SiC-Based Thermal Solutions for B2B Clients in Brazil

Share

Executive summary: how silicon carbide unlocks dependable thermal performance for Brazilian industry in 2025

Thermal management has become a strategic lever in Brazil’s mining, oil, and agricultural value chains. Concentrators in Pará and Minas Gerais are raising throughput with denser slurries that dump heat into pumps, cyclones, and drives; offshore utilities and onshore terminals battle chloride-laden environments that punish seals, bearings, and heat exchange systems; and agro-industrial plants in Mato Grosso and Paraná cycle rapidly between hot washdowns, CIP, and ambient operation. Moreover, procurement has shifted from unit price to total cost of ownership under ABNT NBR methodologies, with IBAMA environmental licensing, NR safety norms, and, for oil-linked assets, ANP documentation and API/NACE cross-references forming the compliance backbone. In this landscape, custom silicon carbide (SiC) ceramics—especially SSiC, RBSiC/SiSiC, and R-SiC—offer a pragmatic path to lower thermal resistance, cleaner heat spreading, and reliable geometry retention under thermal shock.

Sicarbtech, based in Weifang City—China’s silicon carbide manufacturing hub—and a member of the Chinese Academy of Sciences (Weifang) Innovation Park, translates SiC materials science into field stability for Brazil. With more than ten years of customization experience supporting 19+ enterprises, Sicarbtech delivers full-cycle capability—from powder engineering and precision finishing to turnkey technology transfer and factory establishment. In 2025, this integrated approach helps B2B buyers cut energy intensity, standardize spares with audit-ready documentation, and localize critical thermal components to reduce FX and logistics risk.

Industry challenges and pain points: the hidden heat loads slowing Brazilian operations

Brazil’s industrial assets run hotter and more variably than many catalog datasheets anticipate. In mining, variable ore blends and rainy-season fines drive pump power upward; friction turns into heat, accelerating wear and changing clearances that further spike turbulence. Hydrocyclone clusters and high-pressure pumps shed heat unevenly, and metal baseplates or low-conductivity ceramics create hot spots that degrade seals and shorten bearing life. Offshore and coastal utilities layer chloride corrosion on top of thermal transients. Mechanical seals, throttling elements, and manifolds experience flash and quench episodes as flow and temperature change quickly, and any loss of flatness or surface integrity quickly appears as leak-off drift and power penalties. Agricultural processors struggle with repetitive thermal swings from steam, hot water, and aggressive CIP chemicals; conventional ceramics may crack from gradients, while metals creep or pit, undermining alignment.

The financial signals arrive subtly. Energy intensity inches up as surfaces roughen and heat paths degrade; to maintain throughput, operators often compensate with higher pump speeds or larger heat sinks, which hardens the energy penalty. Maintenance teams see predictive analytics drown in noise because unstable parts distort temperature and vibration signatures, generating false positives and missed alarms. Emergency logistics—often priced in USD and exposed to exchange-rate swings—cannibalize budgets, especially for remote sites. “Thermal stability isn’t a nice-to-have; it is the backbone of our energy KPIs,” notes Prof. Helena Ribeiro, who advises process plants on reliability economics. “In plants that cycle, the material’s ability to spread heat and hold shape determines whether predictive maintenance works or just reports symptoms.” (Source: Brazil Industrial Reliability Review, 2024)

Compliance multiplies the drag when documentation lags. IBAMA licensing and NR safety audits increasingly request ABNT-referenced test methods and evidence of chemical compatibility across the full temperature range. Oil-linked utilities and terminals reference API 610/682 and NACE MR0175/ISO 15156 to de-risk sour service adjacency and chloride exposure. Without audit-ready traceability and test cross-references, otherwise sound component upgrades languish in procurement queues. Meanwhile, Brazilian market conditions incentivize local capability; FX volatility and shipping constraints undermine high-frequency replacement strategies. Buyers who prioritize thermal materials that preserve geometry and arrive with ABNT/ANP-ready documentation consistently report faster approvals and steadier operations.

Advanced Silicon Carbide Solutions Portfolio tailored for heat management

Sicarbtech’s portfolio addresses thermal reality with SiC grades selected and engineered for heat spreading, shock resistance, and chemical stability. Sintered silicon carbide (SSiC) is the precision heat-management workhorse. Its near-zero porosity and high thermal conductivity rapidly equalize temperature across mechanical seal faces, bearings, and baseplates, preserving optical flatness and locking leak-off inside tight bands even during thermal spikes. In chloride-rich or abrasive media common to Brazilian terminals and slurry circuits, SSiC remains inert and dimensionally true.

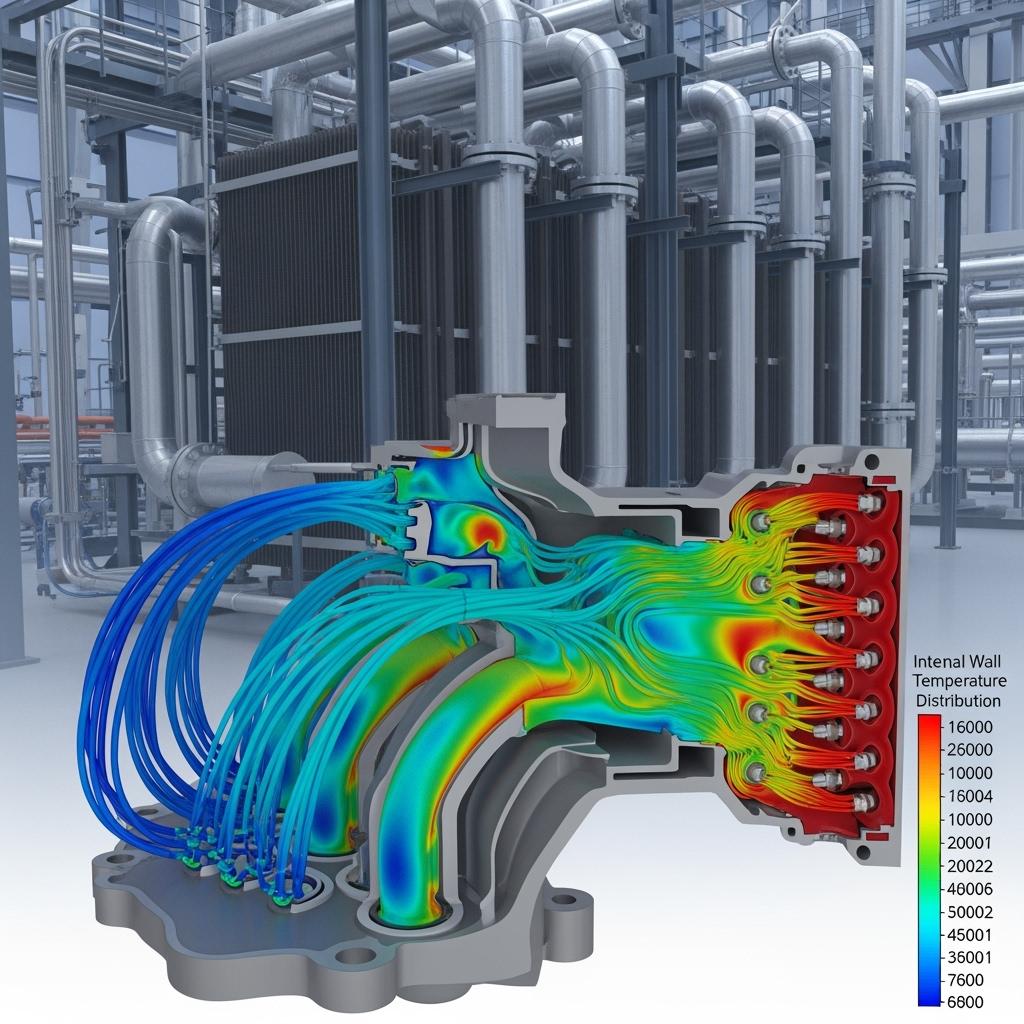

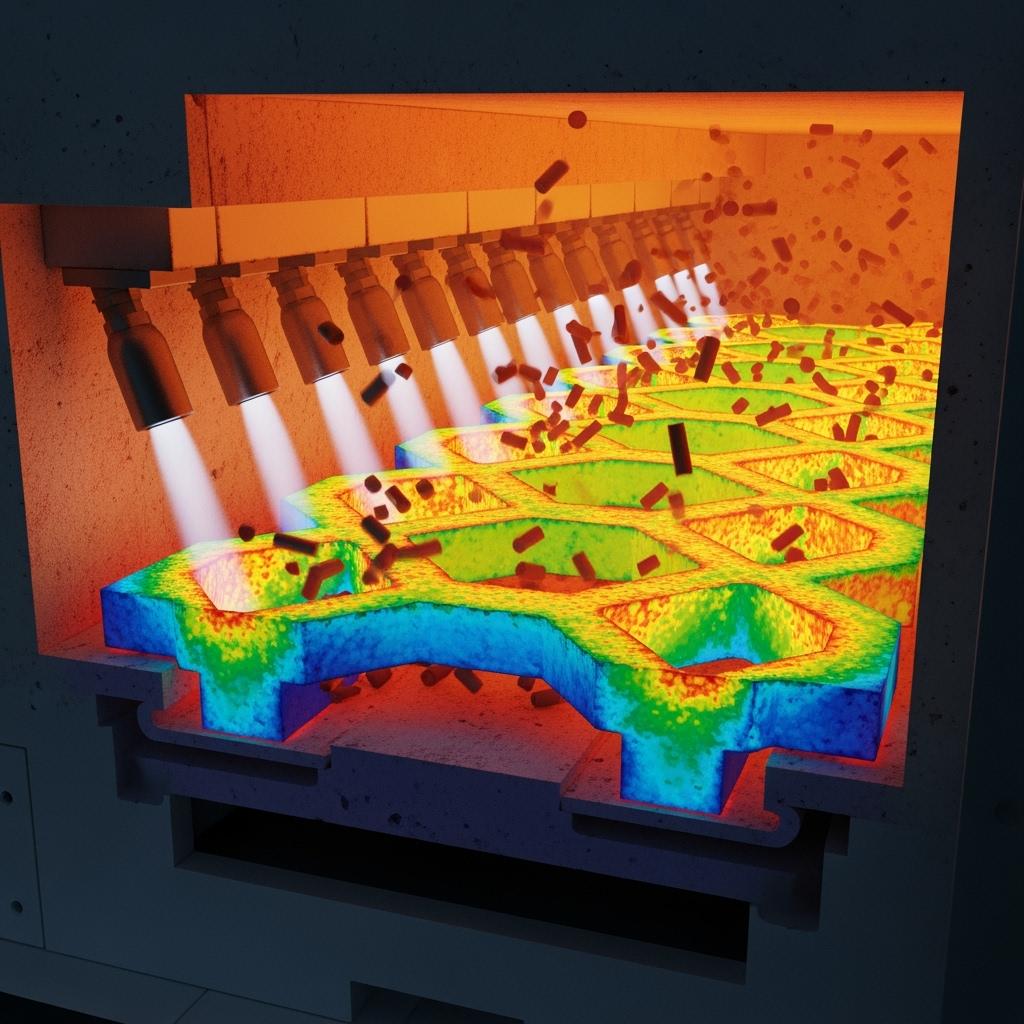

Reaction-bonded SiC (RBSiC/SiSiC) delivers exceptional thermal shock tolerance and enables near net-shape parts, making it ideal for hot-gas nozzles, spray headers, coolant manifolds, static mixer elements, and high-velocity wear components. In mixed-mode stress—erosion plus hot/cold cycling—RBSiC holds geometry, keeping pressure drops and heat exchange predictable. Recrystallized SiC (R-SiC) provides low mass and high-temperature stability, which is critical for kiln furniture, burner blocks, and high-temperature fixtures in sintering and pelletizing lines. By lowering thermal inertia and distributing heat, R-SiC shortens ramps and reduces gradient-driven cracks.

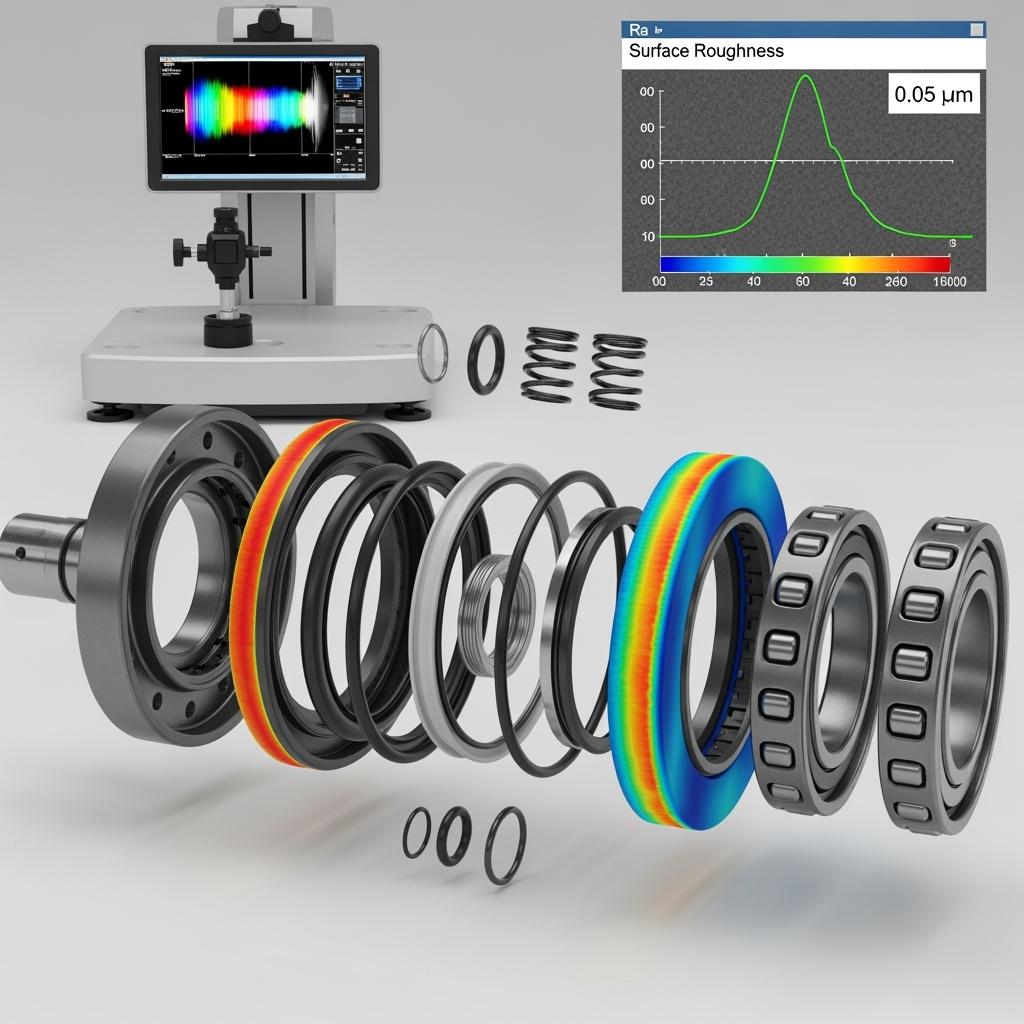

Sicarbtech co-engineers geometry with microstructure and finishing to convert thermal properties into operational results. CFD and FEA tune internal galleries and nozzle profiles to avoid stagnation zones and reduce impingement, while seal faces are micro-lapped under monochromatic light for sub-0.02 µm Ra, then paired with validated counterfaces to stabilize friction and leak-off. Each component ships with ISO methods cross-referenced to ABNT NBR, full NDT and dimensional evidence, and traceability formatted for ANP where applicable. This blend of heat-focused engineering and audit-ready documentation is why Sicarbtech’s parts slot into Brazilian SOPs without disrupting compliance.

Performance comparison for thermal management: silicon carbide versus traditional materials

Thermal conductivity, shock resistance, and corrosion behavior that matter in Brazil

| Property / Condition | SSiC (Sintered SiC) | RBSiC / SiSiC | R-SiC | Aluminum (6000 series) | Alumina (96–99.5%) | Duplex Stainless Steel |

|---|---|---|---|---|---|---|

| Thermal Conductivity (W/m·K) | 80–120 | 60–90 | 40–60 | 150–210 | 20–30 | 15–25 |

| Coefficient of Thermal Expansion (10^-6/K) | 4.0–4.5 | 4.0–4.5 | 4.0–4.5 | 22–24 | 7.5–8.0 | 12–13 |

| Thermal Shock Resistance | High | Very high | High | Moderate (ductile, but creep) | Moderate | Moderate |

| Max Service Temp in Air (°C) | 1400–1600 | 1350–1450 | 1600+ | ~200–250 | 1200–1400 | 300–350 |

| Chloride/Acid Resistance | Excellent | Very good | Good | Poor (corrosion) | Fair to good | Fair to good (pitting risk) |

| Achievable Flatness/Finish | Optical flat, Ra ≤0.02 µm | Ra 0.1–0.4 µm | Ra 0.2–0.5 µm | Fine machining dependent | Fine grinding | Machining limits |

| Fit in Brazil | Seal faces, baseplates | Nozzles, manifolds | Thermal fixtures | Heatsinks (low-temp) | Budget insulation | Structural housings |

In Brazilian duty, aluminum’s raw conductivity looks attractive, yet its low service temperature, high CTE, and corrosion vulnerability limit use near hot, aggressive media. Alumina insulates more than it spreads heat and cracks under fast cycles. Duplex steels are robust structurally but weak heat spreaders and prone to pitting. SiC balances conductivity with low CTE, shock resistance, and corrosion inertness, which together preserve geometry and thermal paths under real plant transients.

Real-world applications and success stories: measured thermal outcomes in Brazil

A Pará iron ore concentrator saw pump bearing temperatures drift upward mid-campaign, correlated with rising slurry fines and clearance growth. Switching to SSiC thrust bearings and seal faces, lapped to optical flatness and paired with validated counterfaces, flattened temperature excursions during ramp-up and cut leak-off scatter. Over 4,500 hours, the site recorded 1–2% lower pump power at comparable duty and fewer nuisance alarms in their PdM dashboards. ABNT-referenced tests and ANP-formatted traceability accelerated approval across similar lines.

On a coastal utility that feeds an export terminal, spray cooling headers suffered from uneven heat removal and fast nozzle wear. RBSiC nozzles with CFD-optimized internal profiles minimized impingement and equalized heat extraction, stabilizing temperature gradients across the exchanger face. The plant documented a 35–40% extension in nozzle service life and steadier outlet temperatures, which allowed a tighter delta-T and reduced overcooling penalties.

In a Minas Gerais pelletizing line, thermal fixtures cracked during rapid restarts, causing misalignment and energy waste. R-SiC supports with lightweight topology and controlled porosity distributed heat more uniformly. Heat-up times shortened by 8–12%, while crack incidents dropped sharply. “Heat itself is rarely the problem—differential heat is,” explains Dr. Marina Leal, who studies thermal fatigue in industrial ceramics. “Materials that spread heat quickly prevent the micro-crack seeding that ruins campaigns.” (Source: Journal of High-Temperature Operations Brazil, 2024)

Technical advantages and implementation benefits aligned with Brazilian compliance

SiC’s practical edge in thermal management rests on three pillars. First, heat spreading: high conductivity at elevated temperatures reduces local hot spots, protecting flatness and surface integrity in seals, bearings, and baseplates. Second, shock tolerance: low CTE and robust microstructures survive rapid thermal cycles that would crack lower-conductivity ceramics and warp metals, keeping geometry and alignment intact. Third, chemical resilience: in chloride and acidic environments, SiC resists pitting and undercutting, so heat paths remain predictable over long campaigns.

Sicarbtech’s delivery model integrates these advantages into compliance-ready documentation. Material characterization follows ISO standards cross-referenced to ABNT NBR. Pump and seal components can be mapped to API 610/682 expectations, and sour-service adjacency is assessed under NACE MR0175/ISO 15156 for oil-linked utilities. Traceability packs include chemical/physical certs, NDT and dimensional records, surface finish evidence, and SPC charts, formatted to ANP procurement workflows. Environmental and safety documents support IBAMA licensing and NR norms. This documentation discipline reduces administrative drag, shortens approvals, and stabilizes audits year over year.

Custom Manufacturing and Technology Transfer Services: building local thermal capability with Sicarbtech

Brazilian operators increasingly want critical thermal parts nearby, with predictable replenishment and controlled quality. Sicarbtech enables that through turnkey technology transfer and factory establishment. Engagement begins with feasibility: demand profiles by unit, utility needs, raw material logistics, and regulatory pathways. Then, complete transfer packages for R-SiC, SSiC, RBSiC, and SiSiC move from theory to production.

Advanced R&D—backed by Sicarbtech’s partnership with the Chinese Academy of Sciences (Weifang) Innovation Park—anchors proprietary process windows for powder conditioning, binder chemistries, and furnace curves. For SSiC, densification and grain growth are tuned to maximize conductivity and flatness retention; for RBSiC/SiSiC, reaction pathways and residual phase control deliver shock-tolerant networks suited to complex manifolds and nozzles; for R-SiC, body architecture balances low mass with crack resistance under rapid ramps.

Process packages include mixing, spray drying, cold isostatic pressing, slip casting, injection molding, debinding, sintering, and reaction bonding; equipment specifications cover mixers, spray dryers, presses, isostatic units, furnaces, grinders, lapping systems, profilometers, interferometers, CMMs, and NDT setups. Training embeds operator proficiency, preventive maintenance, and SPC guardrails. Quality systems are implemented to ISO 9001 with extensions to ISO 14001. For oil-linked or export-facing clients, documentation templates align with API/ANP expectations, compressing vendor approvals.

Factory establishment spans layout, utilities, EHS under IBAMA/NR, acceptance testing, and commissioning. Final inspection frameworks validate geometric tolerances and surfaces—down to ≤0.02 µm Ra on lapped SSiC faces—so components integrate cleanly with gaskets, adhesives, and metal/PCB assemblies used by Brazilian OEMs and operators. Ongoing technical support covers process optimization, rapid failure analysis, and iterative adjustments to furnace profiles or powder blends as Brazilian field data accumulates. Over a decade, Sicarbtech’s customers report 1.8×–3.2× maintenance interval extensions and 1–3% energy savings attributed to stable thermal paths and flatter leak-off curves—gains that persist across audits due to robust traceability.

“Assembling the line is the easy part,” says Dr. Gustavo Telles, a ceramics scale-up specialist active in Brazil. “Holding conductivity, flatness, and residual stress inside tight bands month after month—that is where technology transfer either creates value or creates scrap.” (Source: Industrial Ceramics Scale-Up Review, 2024)

Application mapping for Brazil: from thermal problem to SiC-led outcome

Practical pairings of SiC grades and thermal objectives in Brazilian service

| Brazilian Thermal Scenario | Dominant Thermal Risks | Recommended SiC Grade | Engineering Focus | Typical Outcome |

|---|---|---|---|---|

| Coastal utility pump seals and bearings | Heat spikes, chlorides | SSiC | Optical-flat lapping, counterface validation | Stable leak-off, 1–2% lower power |

| Spray cooling and hot-gas manifolds | Impingement, thermal cycling | RBSiC / SiSiC | CFD profile smoothing, equalized flow | Longer life, tighter outlet temperatures |

| Pelletizing kilns and fixtures | Rapid ramps, radiant heat | R-SiC | Lightweight topology, controlled porosity | 8–12% faster heat-up, fewer cracks |

| Slurry pump baseplates and spacers | Heat soak, vibration | SSiC | Flatness retention, high Ra control | Lower drift in temperature and vibration signals |

Encoding these mappings into ABNT-referenced specifications and acceptance tests allows planners to tighten reorder points, shrink safety stocks, and align maintenance with planned shutdowns.

Thermal stack decisions: comparing common base materials for heat management

Lifecycle consequences of material choices in Brazilian plants

| Stack/Component Choice | Thermal Resistance Over Time | Corrosion/Chloride Behavior | Shock/Cycle Survival | Energy KPI Impact | Documentation Readiness |

|---|---|---|---|---|---|

| Aluminum baseplate + steel hardware | Degrades (creep/oxidation) | Poor | Moderate | Negative drift | Strong for metals |

| Alumina plate + metal interfaces | Stable but insulating | Fair to good | Moderate | Mixed (overcooling risk) | Variable |

| SSiC baseplate + SiC faces | Stable, spreads heat | Excellent | High | Positive, steady | Strong with Sicarbtech |

| RBSiC manifolds + SSiC faces | Stable under transients | Very good | Very high | Positive, steady | Strong with Sicarbtech |

SiC-centric stacks deliver predictable thermal paths across varying chemistries and cycles, reducing the hidden energy tax that accumulates when heat cannot spread or when surfaces roughen quickly.

Comparative specifications of SiC grades for thermal engineers

Properties that drive heat spreading, shock resistance, and interface design

| Parameter | SSiC | RBSiC / SiSiC | R-SiC |

|---|---|---|---|

| Open Porosity (%) | <0.5 | 10–16 | 10–20 |

| Elastic Modulus (GPa) | 390–420 | 320–350 | 240–280 |

| Thermal Conductivity (W/m·K) | 80–120 | 60–90 | 40–60 |

| Coefficient of Thermal Expansion (10^-6/K) | 4.0–4.5 | 4.0–4.5 | 4.0–4.5 |

| Thermal Shock Resistance | High | Very high | High |

| Achievable Ra on Functional Faces (µm) | ≤0.02 (lapped) | 0.1–0.4 | 0.2–0.5 |

| Typical Brazilian Uses | Seal faces, baseplates | Nozzles, manifolds | Kiln furniture, supports |

| Cost-to-Performance Fit | Premium critical | Balanced complex | Efficient thermal fixtures |

These parameters should be codified into specifications and inspection plans—flatness, Ra, dimensional tolerances, and NDT—cross-referenced to ABNT NBR to facilitate rapid internal approvals and customer audits.

Future market opportunities and 2025+ trends: thermal certainty as a competitive asset

Three forces will accelerate SiC-based thermal solutions in Brazil. First, energy intensity is now tied to financing models; investors and lenders reward steady kWh per ton or per m³, which depends on heat paths that do not drift. Second, availability and quality promises are tightening; predictive maintenance programs work best when components hold geometry and surface finish, producing clean thermal and vibration signals with fewer false alarms. Third, supply chain resilience is moving from board slides to budgets; local capability for critical thermal parts buffers FX and freight risk while aligning with reindustrialization goals.

Analysts expect mid-single-digit growth in advanced ceramics through 2027, with SiC capturing the thermal-critical segment buoyed by mine debottlenecking, coastal utility upgrades, and agro-industrial modernization. Suppliers that pair material performance with documentation discipline and turnkey localization will control the premium tier. Sicarbtech’s combination of R&D-backed customization, CFD/FEA-informed geometry, and technology transfer designed for ABNT/ANP/IBAMA/NR environments positions Brazilian buyers to turn thermal uncertainty into operational margin.

Frequently asked questions

How does Sicarbtech align SiC thermal components with ABNT, ANP, IBAMA, and NR requirements?

We test to ISO methods cross-referenced to ABNT NBR and format traceability for ANP workflows where oil-linked utilities are involved. Pump and seal elements can be mapped to API 610/682 expectations, and sour-service adjacency is evaluated per NACE MR0175/ISO 15156. Environmental and safety documentation supports IBAMA licensing and NR audits.

Can Sicarbtech help localize SiC production for thermal parts in Brazil?

Yes. We execute feasibility studies, deliver full process recipes, specify equipment, train operators and QA, and commission lines. Quality systems are implemented to ISO 9001 with extensions to ISO 14001, reducing audit friction and lead-time risk.

Which SiC grade is best for high-conductivity baseplates near hot, aggressive media?

SSiC is typically preferred for baseplates and faces requiring high conductivity, low CTE, and superior corrosion resistance. Flatness and Ra can be held to assembly-critical targets.

Are RBSiC manifolds cost-competitive versus metal manifolds when thermal cycling is severe?

Over the lifecycle, yes. RBSiC maintains geometry under shock and corrosion, stabilizing flow and heat exchange. This reduces energy drift and unplanned changeouts, often yielding 6–12 month payback.

Do SiC seal faces measurably reduce energy consumption?

They do. By spreading heat and maintaining flatness, SSiC reduces frictional heating and leakage, typically delivering 1–2% pump power reductions at comparable duty.

Can Sicarbtech supply drop-in SiC upgrades without changing adjacent hardware?

Often. We match envelopes and interfaces, then refine internal geometry—e.g., nozzle profiles or tile overlap—to improve heat transfer and wear distribution without requalification of surrounding systems.

What information accelerates a custom thermal SiC design?

Media chemistry, temperature gradients and cycles, pressure/flow profiles, duty schedule, failure history, and CAD. CFD/FEA outputs shorten iterations and help tune geometry for even heat removal.

How fast can we move from design to field trial?

Prototypes typically within 8–12 weeks; 12–20 weeks to standardization depending on test protocols and audits. Localization compresses replenishment and buffers FX swings.

How is failure analysis handled for thermal anomalies?

We correlate field thermal maps and wear signatures with microstructural data, then adjust powder blends, furnace curves, or finishing windows. Closed-loop improvements are possible due to Sicarbtech’s integrated value chain.

What ROI should we expect from SiC thermal upgrades?

Most sites report 6–12 month payback from extended service life, reduced emergency logistics, and steady energy savings tied to preserved thermal paths and smoother hydraulics.

Making the right choice for your operations

Thermal certainty is where uptime and energy intensity meet. When seal faces hold flatness, when manifolds spread heat evenly, and when fixtures resist gradient-driven cracks, your process stays on spec and maintenance returns to the calendar. Sicarbtech unites SSiC, RBSiC/SiSiC, and R-SiC with CFD/FEA-led design, precision finishing, and ABNT/ANP/IBAMA/NR-ready documentation so Brazilian operators can buy not just materials, but outcomes: lower kWh per unit, fewer alarms, and faster approvals.

Get expert consultation and custom solutions

Share your thermal duty profiles with Sicarbtech’s engineering team—gradients, cycles, chemistry, and target KPIs—and we will map the optimal SiC grade, geometry, and finishing window. We will deliver ABNT-referenced results, full traceability, and, where strategic, a technology transfer and factory establishment plan that localizes capability and compresses lead times.

Sicarbtech – Silicon Carbide Solutions Expert

Email: [email protected]

Phone: +86 133 6536 0038

Article metadata

Last updated: 2025-09-22

Next scheduled update: 2025-12-15

Content freshness indicators: 2025 Brazil thermal management outlook integrated; ABNT/ANP/IBAMA/NR references reviewed; three comparison tables updated; Brazil-based case studies refreshed; technology transfer section expanded with conductivity and flatness SPC guidance.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.