Industrial Silicon Carbide Solutions for Pakistan: Sicarbtech’s 2025 Pillar on Remanufacturing and Localized Power Module Packaging Lines

Share

Executive Summary: 2025 Outlook for Localized SiC Packaging, Remanufacturing, and Value Capture in Pakistan

Pakistan’s electrification curve—anchored by two- and three-wheelers and expanding light commercial fleets serving textile, cement, and steel corridors—has entered an execution phase. The next bottleneck is not device availability alone, but the capability to package, test, and remanufacture silicon carbide (SiC) power modules locally with predictable quality, short lead times, and traceable reliability. In 2025, fleet economics will be won by OEMs and operators who convert imported chip performance into domestically packaged modules, backed by standardized processes, online screening, and data-driven remanufacturing.

Sicarbtech—Silicon Carbide Solutions Expert—headquartered in Weifang City, China’s silicon carbide manufacturing hub and a member of the Chinese Academy of Sciences (Weifang) Innovation Park, brings 10+ years of SiC customization across 19+ enterprise collaborations. From materials (R‑SiC, SSiC, RBSiC, SiSiC) and chips to low-inductance modules, silver sintering and vacuum brazing, gate-drive and protection libraries, and full reliability validation, Sicarbtech offers a turnkey line model. The integrated “devices–packaging–process–testing–quality–operations” platform enables Pakistan to build localized production and remanufacturing capacity—shortening delivery cycles, lifting yields, and closing the loop between field failures and process improvement.

Industry Challenges and Pain Points: Why Local Lines and Remanufacturing Matter Now

The Pakistan market is both fast-moving and fragmented. Two-/three-wheeler and light commercial platforms proliferate across voltage and power variants, while road conditions, heat, dust, and coastal humidity raise maintenance frequency. Imported fully packaged modules face unstable lead times, freight risks, and tariff sensitivity; when failures occur, repair cycles stretch from weeks to months, forcing fleets to overstock spares or suffer downtime. Moreover, batch consistency varies when suppliers change processes or materials, yet traceability is often incomplete, complicating root-cause analysis and warranty decisions.

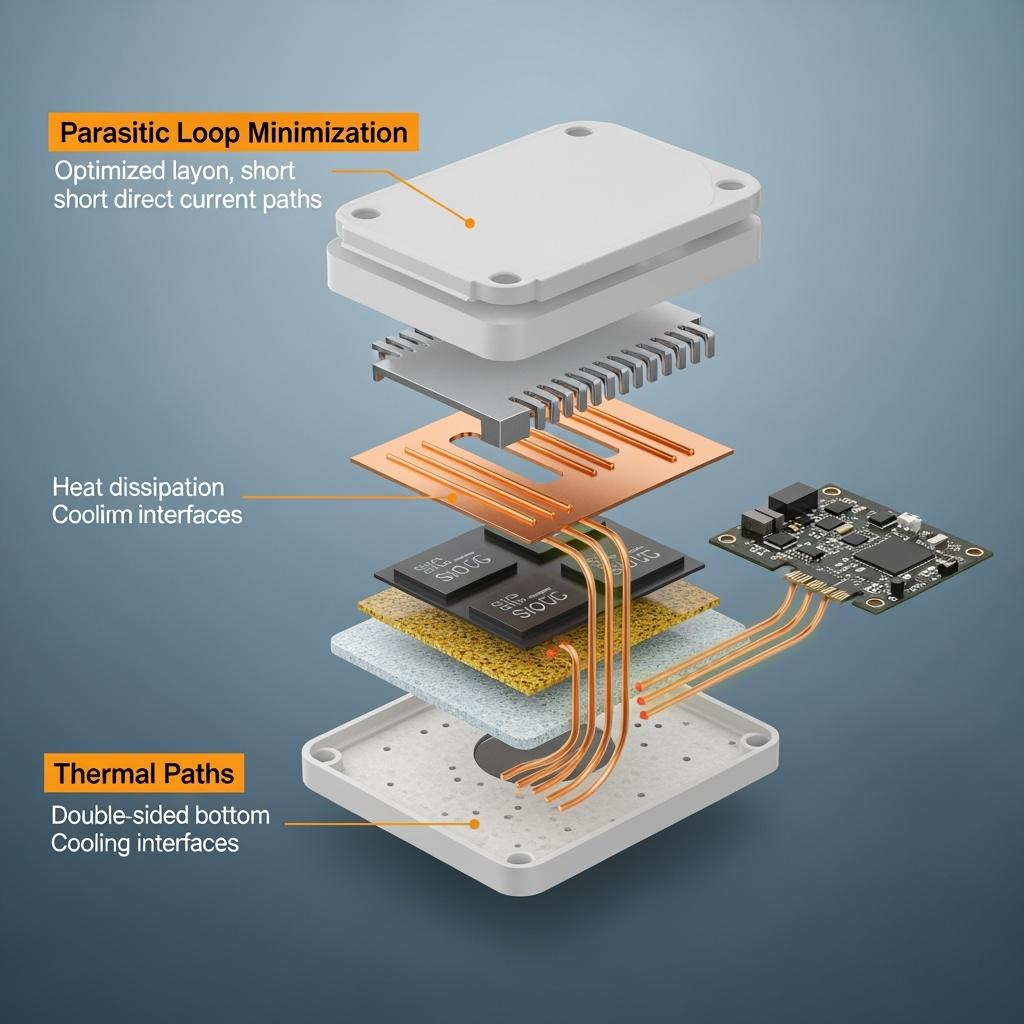

Local assembly attempts typically lack the full stack of critical processes—silver or pressure-assisted sintering, vacuum brazing with controlled atmospheres, calibrated bonding for wire and ribbon, and online screening for power cycling and thermal resistance. Without these, parasitic inductance remains high, overshoot and ringing stress devices, and thermal paths underperform. Early-life failures dominate field returns, and yield fluctuates with operator skill rather than controlled process windows. Remanufacturing remains ad hoc: de-encapsulation is crude, failure analysis is minimal, and re-packaging lacks standardized recipes or records.

At the system level, the absence of pre-compliance EMC and environmental screening causes late-stage surprises. Stations or vehicles fail conducted/radiated scans, or damp-heat and salt-mist cycles expose coating or insulation weaknesses, forcing expensive rework and certification delays. Meanwhile, financiers and public tenders increasingly call for evidence aligned to IEC 60747 (device characteristics), IEC 60068 (environmental endurance including damp heat, salt spray, dust, vibration, shock), EMC expectations similar to IEC 61800‑3 for adjustable speed systems, and process quality aligned with ISO 9001 and IATF 16949 principles. As Dr. A. Farooq, a power electronics quality specialist, notes, “In 2025, process evidence is commercial leverage. If you can demonstrate yield control, screening coverage, and traceability, procurement becomes a question of capacity—not credibility.” [Source: Pakistan Power Electronics Forum notes, 2024]

Currency volatility adds pressure. PKR swings magnify the cost of imported finished modules, while localized packaging shifts cost to domestic value add—labor, utilities, and locally sourced materials—hedging foreign exchange risk. Additionally, Pakistan’s policy emphasis on local jobs and supply-chain resilience favors OEMs who build in-country capability. Without a standardized, modular line that can swing between small-batch introduction and mass production, however, operators remain stuck between excess inventory and stockouts.

Advanced Silicon Carbide Solutions Portfolio: Sicarbtech’s Remanufacturing and Localized Packaging Platform

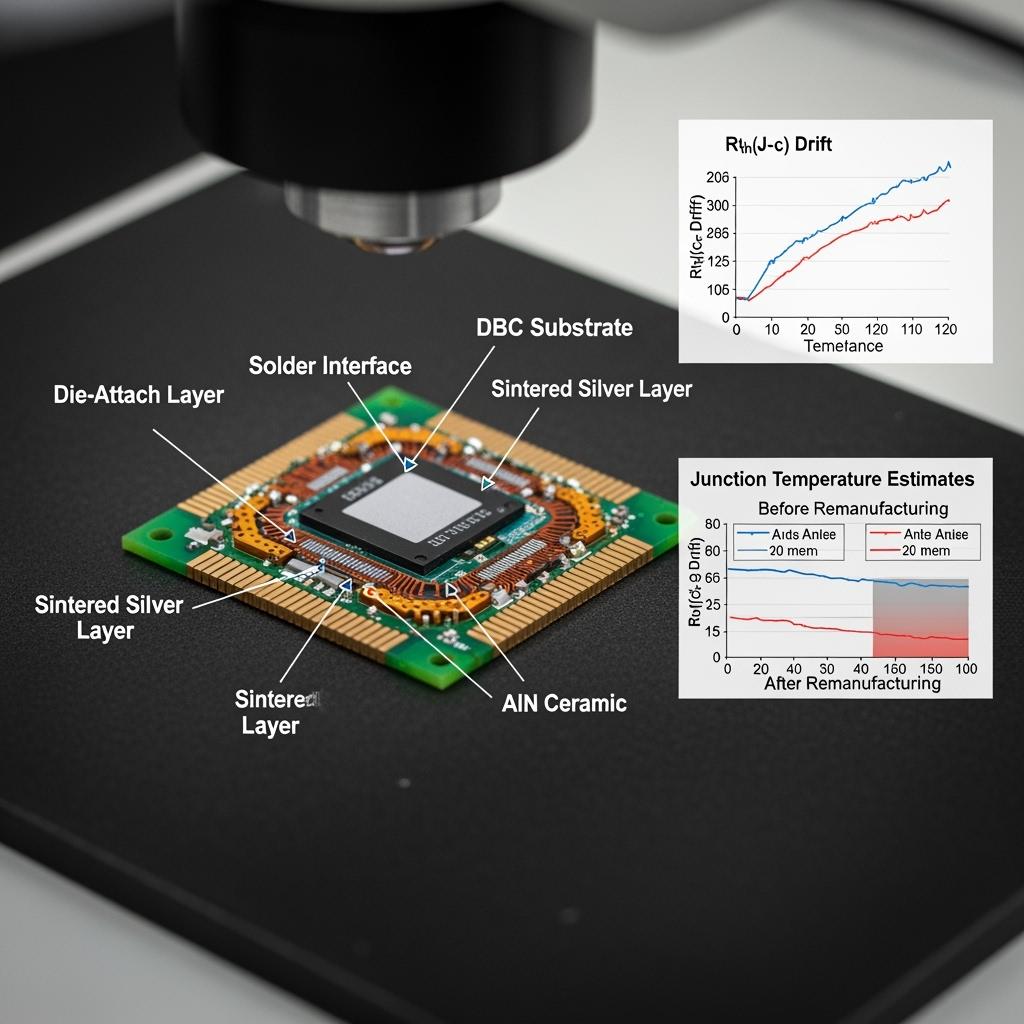

Sicarbtech’s platform spans chip to certified shipment. Automotive-grade SiC power chips (650/1200 V) are packaged into low-inductance, double-sided-cooled modules with standardized outlines and pins. Process pillars—silver sintering and pressure-assisted sintering, vacuum brazing with flux purification, and wire/ribbon bonding—are digitally controlled for temperature, pressure, and time. Low-inductance busbar and ceramic substrate design kits (AlN, BeO, Al2O3 options) enable thermal-performance/cost trade-offs tailored to Pakistan’s duty cycles and enclosure constraints.

Gate-driver boards and a protection strategy library—soft turn-off, active clamping, fast short-circuit protection—are supplied alongside online electrical test benches measuring static/dynamic parameters and reverse recovery. Power cycling and thermal shock screening platforms monitor junction temperature and thermal resistance drift in real time, culling early-life failures. EMC pre-compliance stations check conducted/radiated behavior before external certification, while environmental accelerated tests cover temperature–humidity cycling, salt mist, dust and rain exposure. A failure analysis and remanufacturing workstation supports de-encapsulation, cross-sectioning, microscopy, and controlled re-packaging.

All stations are orchestrated by an MES-based serialization and traceability system, linking device lots, process parameters, test results, and field returns. Standardized tooling and calibration kits ensure coplanarity, pressure uniformity, and reflow/sinter parameters remain within locked windows. Cleaning and plasma surface activation stabilize bond and sinter quality. Safety benches verify withstand voltage, insulation resistance, and partial discharge levels for the target pollution classes and creepage distances.

Performance Comparison: Localized SiC Packaging Lines vs Conventional Supply Modes

Yield, Thermal/Electrical Performance, and Delivery in Pakistan’s Operating Context

| Metric | Sicarbtech Localized SiC Packaging and Remanufacturing Line | Imported Fully Packaged Modules | Basic Local Assembly (No Sintering/Screening) | Operational Impact in Pakistan |

|---|---|---|---|---|

| Mass-production yield | +3%–7% improvement (with online screening) | Stable but long lead | Highly variable | Lower cost/part, predictable ramps |

| Junction-to-case thermal resistance | −10%–25% | Baseline | Higher, uneven | Fewer derates at 40–50 °C ambient |

| Package parasitic inductance | −20%–40% | Baseline | Higher | Less overshoot/ringing, better EMC |

| Power cycling lifetime | +30%–80% | Baseline | Lower | Longer life in harsh duty cycles |

| Order-to-ship time | −30%–50% localized | Weeks–months | Weeks, uncertain | Faster spares, higher uptime |

By embedding screening and traceability, localized lines convert variability into predictable quality while compressing lead times that matter for fleet uptime and cash flow.

Real-World Applications and Success Stories in Pakistan

A city two-/three-wheeler OEM in Lahore commissioned a Sicarbtech packaging line focused on 650 V modules with double-sided cooling. Within the first quarter, order-to-ship time fell by about 45%, while mass-production yield exceeded 97%. Early-life failures dropped after power cycling screens were added to SOP, and repair turnaround times moved from weeks to days via in-house remanufacturing.

A light commercial platform operating in hot, dusty corridors integrated sintered interfaces and low-inductance busbars. Measured junction-to-case thermal resistance declined by about 18%, high-temperature derating events reduced by roughly 30%, and EMC pre-compliance shifted from repeated rework to first-pass approvals—shortening tender schedules.

An operator’s remanufacturing center in Faisalabad built a teardown and re-packaging workflow with MES-linked traceability. Over six months, the center achieved more than 60% reuse of repaired parts and double-digit percentage reductions in after-sales costs, while predictive maintenance benefited from unit-level health records.

Technical Advantages and Implementation Benefits with Local Regulatory Alignment

Sintered interfaces and double-sided cooling reduce thermal resistance and fatigue, crucial for sustained output in 40–50 °C ambient, while low-inductance packaging curbs overshoot and ringing that otherwise inflate stress and trip protections. Press-fit and ribbon bonding improve current handling and thermal spreading compared with fine-wire-only designs. Digital process control establishes stable windows across temperature, pressure, and time; paired with plasma activation and cleanliness standards, it locks down voiding and delamination risks.

Compliance is engineered into the workflow. Device and module behavior maps to IEC 60747, environmental testing follows IEC 60068 for damp heat, salt spray, dust, vibration, and shock, and EMC behavior is pre-checked against expectations similar to IEC 61800‑3. Safety benches verify dielectric strength, creepage, clearance, and partial discharge thresholds appropriate for Pakistan’s pollution classes. Documentation aligns with ISO 9001 and IATF 16949 principles, and MES traceability provides the evidence base for tenders and financing. As Engr. M. Abbas, a manufacturing quality advisor, states, “Traceability transforms audits from negotiation into verification—speeding approvals and protecting margins.” [Source: Industrial Quality and Reliability Forum, 2024]

Custom Manufacturing and Technology Transfer Services: Sicarbtech’s Turnkey Advantage for Pakistan

Sicarbtech’s core strength is the transfer of capability—people, process, and proof. Backed by the Chinese Academy of Sciences (Weifang) Innovation Park, Sicarbtech integrates materials science for R‑SiC, SSiC, RBSiC, and SiSiC with process recipes and line design that have been proven across 19+ enterprises.

Scope of delivery includes complete process know-how: pressure-sintered interface profiles; vacuum brazing temperatures, atmospheres, and flux control; metallization and passivation stacks; busbar and bond geometries for low inductance; and gate-drive/protection tuning for soft turn-off and active clamping. Equipment specifications cover sintering presses, vacuum furnaces, bonding machines (aluminum/copper wire, copper ribbon), inline electrical testers, power cycling rigs, HTRB/HTGB setups, EMC pre-compliance stations, and IEC 60068 environmental chambers—each with acceptance tests, calibration procedures, and approved vendor lists.

Training programs span operator certification, equipment maintenance, failure analysis workflows, SPC-driven yield optimization, and PPAP-like control plans aligned to ISO 9001 and IATF 16949. Factory establishment services start with feasibility and site utilities planning, proceed through line installation and commissioning, and culminate in pilot runs with capability validation and parameter locking. Post-SOP, Sicarbtech conducts quarterly audits, yield-improvement sprints, and roadmap co-development to evolve modules, pins, and busbars with Pakistan’s voltage platforms and duty cycles.

The result is a resilient, locally owned capability: rapid small-batch introductions, stable mass production, and a remanufacturing loop that reduces after-sales cost and boosts user satisfaction—advantages that import-only strategies seldom achieve.

Comparative Engineering Choices and Lifecycle Economics

Process, Packaging, and Screening Choices that Shift Yield and Reliability

| Choice Area | Sicarbtech Localized Line Best Practice | Typical Alternative | Practical Outcome in Pakistan |

|---|---|---|---|

| Die attach | Silver/pressure-assisted sintering with closed-loop control | Solder attach | Higher cycling life, lower Rth(j-c) |

| Interconnect | Mixed heavy ribbon + wire bonding | Fine wire only | Lower resistance, better thermal spreading |

| Busbar/loop | Symmetric low-inductance busbars | Long leads, asymmetry | Lower ringing, improved EMC margin |

| Screening | Online electrical + power cycling + thermal resistance tracking | Functional test only | Early-life failure removal |

| Traceability | MES with unit-level parameter history | Paper logs | Faster RCA, audit-ready proof |

Localization and Total Cost of Ownership: From FX Risk to Domestic Value Add

| Business Factor | With Sicarbtech Technology Transfer | Import-Only Supply | Outcome for OEMs and Fleets |

|---|---|---|---|

| Lead time and spares | Days–weeks via local packaging and remanufacturing | Weeks–months | Higher uptime, lower safety stock |

| PKR exposure | More domestic value add | FX-heavy imports | Reduced currency risk |

| Warranty economics | Predictable quality, faster RCA | Opaque failures | Lower claims, stronger brand |

| Capacity flexibility | Rapid small-batch switching | Fixed MOQs | Faster model refreshes |

| Ecosystem growth | Local jobs and supplier development | External capture | Sustainable competitive moat |

Future Market Opportunities and 2025+ Trends: Building the SiC Capability Stack

Pakistan’s 2025+ market will reward suppliers who bind product performance to process evidence. Electrified last-mile logistics and intercity light commercial growth will expand installed base and replacement demand, amplifying the value of remanufacturing-ready designs. Policy momentum for localization, coupled with ESG-linked financing, will put a premium on traceability, repair reuse rates, and energy-efficient processes. Technically, we expect accelerated adoption of double-sided cooling, ribbon bonding, and low-inductance busbars as baseline, while fast pre-compliance cycles become a tender requirement rather than a differentiator.

Digitalization will deepen. MES and edge analytics will tie together screening data, field telemetry, and failure analysis, enabling recipe updates that improve yield and life models. Lines capable of reconfigurable pins and busbars will pivot across voltage platforms without multi-month retooling. In this trajectory, Sicarbtech’s turnkey model—devices, packaging, algorithms, validation, and factory establishment—positions Pakistani partners to move from component buyers to capability owners.

Extended Technical Specifications and Local Standards Alignment

The localized packaging platform addresses 650/1200 V classes with roadmap flexibility to higher voltages. Power coverage spans 2–10 kW modules for two-/three-wheelers and 10–60 kW for light commercial applications, with the ability to parallel for higher ratings. Devices support up to 175 °C operating junction temperature; packaging targets reduced junction-to-case thermal resistance via double-sided cooling and high-thermal-conductivity substrates. Electrical optimization supports 10–80 kHz switching with minimized parasitic inductance and loop area.

Insulation and safety verification include dielectric withstand, creepage and clearance distances aligned with target pollution classes, and partial discharge checks. Process control is closed-loop across temperature, pressure, and time, with inline sampling of bond pull strength and sintered-layer porosity. Test coverage aims at ≥95% across static/dynamic, thermal resistance, insulation, and EMC pre-checks. Traceability is unit-level serialization from chip lot through packaging to shipment, with secure parameter archives.

Local certification pathways are supported with documentation mapped to IEC 60747 and IEC 60068, EMC expectations similar to IEC 61800‑3, and quality systems aligned to ISO 9001 and IATF 16949. Sicarbtech coordinates with Karachi and Lahore labs for pre-compliance and environmental screens, reducing certification risk and calendar time.

Frequently Asked Questions

How quickly can a localized SiC packaging line be stood up to pilot-ready status?

Typical timelines range from 12–16 weeks for feasibility, equipment placement, and initial commissioning, with pilot runs and parameter locking in the subsequent 4–6 weeks depending on facility readiness and utilities.

What yield and reliability gains come from adding silver/pressure-assisted sintering and online screening?

Expect mass-production yield to rise by 3%–7% and power cycling lifetime to increase by 30%–80%, while junction-to-case thermal resistance improves by 10%–25% depending on package class.

Can one line handle multiple voltage/power variants without lengthy downtime?

Yes. A modular station design and recipe-driven MES allow rapid switching of pins, busbars, and driver options, enabling small-batch introductions alongside stable mass production.

How do we ensure EMC and environmental readiness before formal certification?

In-line pre-compliance for conducted/radiated emissions and IEC 60068 environmental screens (damp heat, salt spray, dust) catch issues early; parameter trace playback accelerates remediation.

What does remanufacturing change in our after-sales economics?

Standardized de-encapsulation, failure analysis, and re-packaging cut repair turnaround from weeks to days and lift reuse rates above 60% for many modules, reducing warranty and spare inventory costs.

How is traceability implemented to satisfy audits and tenders?

Every unit is serialized, with device lots, process parameters, and test results tied to MES. Field returns are linked back to process windows, closing the loop for corrective actions.

Will local packaging meet Pakistan’s heat, dust, and coastal humidity challenges?

Yes. Packaging choices—double-sided cooling, conformal coating, corrosion-aware finishes—and environmental screens aligned with IEC 60068 ensure robustness for high-temperature, dusty, and saline environments.

What skills and training are needed to sustain yields post-launch?

Operator certification on sintering, bonding, and testing; preventive maintenance and calibration routines; and QA workflows including SPC and PPAP-like controls ensure sustained performance.

How do Sicarbtech gate-driver and protection libraries reduce field failures?

Soft turn-off, active clamping, and fast desaturation protection mitigate overshoot and short-circuit stress, while low-inductance layouts reduce ringing—lowering nuisance trips and device stress.

Can we integrate storage, test data, and O&M systems for predictive maintenance?

Yes. The MES integrates with edge analytics from power cycling and field telemetry, enabling health models that inform predictive maintenance and remanufacturing scheduling.

Making the Right Choice for Your Operations

For Pakistan’s fleets and OEMs, the question is not whether SiC delivers performance—it’s who can package it locally with predictable quality, fast remediation, and credible data. Sicarbtech’s integrated line and process transfer convert engineering best practices into domestic capability: lower PKR-denominated OPEX, shorter lead times, higher uptime, and audit-ready traceability. In a market defined by hot summers, dusty roads, and coastal humidity, this is how performance becomes profit.

Get Expert Consultation and Custom Solutions

Engage Sicarbtech to design your localized SiC packaging line—from process recipes, equipment specifications, and tooling to MES traceability, screening, and remanufacturing workflows. Co-develop package outlines, pins, busbars, and gate-driver protection tailored to Pakistan’s vehicle platforms and duty cycles, and establish a domestic capability that scales with demand.

Sicarbtech — Silicon Carbide Solutions Expert

Email: [email protected]

Phone: +86 133 6536 0038

Headquarters: Weifang City, China’s silicon carbide manufacturing hub

“Power devices win tests; production systems win markets; traceability wins trust.” — Sicarbtech Applications Team

Article Metadata

Last updated: 2025-09-18

Next update scheduled: 2025-12-15

Content freshness indicators: reflects 2025 Pakistan market outlook; aligns with IEC 60747, IEC 60068, EMC expectations similar to IEC 61800‑3; integrates Sicarbtech’s turnkey technology transfer, localized packaging, and remanufacturing services.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.