Silver Sintering and Vacuum Brazing Packaging Materials and Process Kits for Long‑Life SiC Power Modules

Share

On hot June afternoons in Punjab, when inverter cabinets breathe 50°C air and dust rides every breeze, the longevity of a power module is written not only in silicon but in the invisible layers beneath it. Silver Sintering and Vacuum Brazing Packaging Materials and Process Kits for Long‑Life SiC Power Modules are the quiet authors of that story. In Pakistan’s textile, cement, and steel corridors—where 50–250 kW string inverters and industrial drives are surging—Sicarbtech’s metallurgical stack transforms thermal stress and vibration into predictable, long‑life performance. What changes in the field is deceptively simple: cooler junctions, calmer thermomechanical strain, and modules that keep their promise season after season.

Silver Sintering and Vacuum Brazing Packaging Materials and Process Kits for Long‑Life SiC Power Modules product overview and 2025 market relevance

As the market pivots to 1500 V DC platforms and higher switching frequencies, the mechanical and thermal demands on SiC modules climb steeply. Silver Sintering and Vacuum Brazing Packaging Materials and Process Kits for Long‑Life SiC Power Modules meet this challenge by replacing conventional soldered interfaces with high‑thermal‑conductivity, high‑reliability joints. The silver sinter die‑attach and vacuum‑brazed substrate and baseplate bonds create a low‑impedance heat path and a mechanically compliant stack that resists fatigue from daily thermal swings. For Pakistan’s commercial and industrial rooftops and ground‑mounted distributed plants, this means smaller heat sinks, fewer fans, and stable operation under weak‑grid dynamics without derating.

Sicarbtech packages these advantages as integrated materials and process kits aligned to 1000/1500 V string inverter and ESS/wind converter requirements. From pre‑form paste and sinter foils to braze alloys, surface preparation chemistries, fixtures, and furnace profiles, Silver Sintering and Vacuum Brazing Packaging Materials and Process Kits for Long‑Life SiC Power Modules reduce trial‑and‑error cycles. Moreover, with local capability building increasingly favored in tenders, the kits anchor technology transfer that helps Pakistani partners stand up repeatable, certifiable production.

Silver Sintering and Vacuum Brazing Packaging Materials and Process Kits for Long‑Life SiC Power Modules technical specifications and advanced features

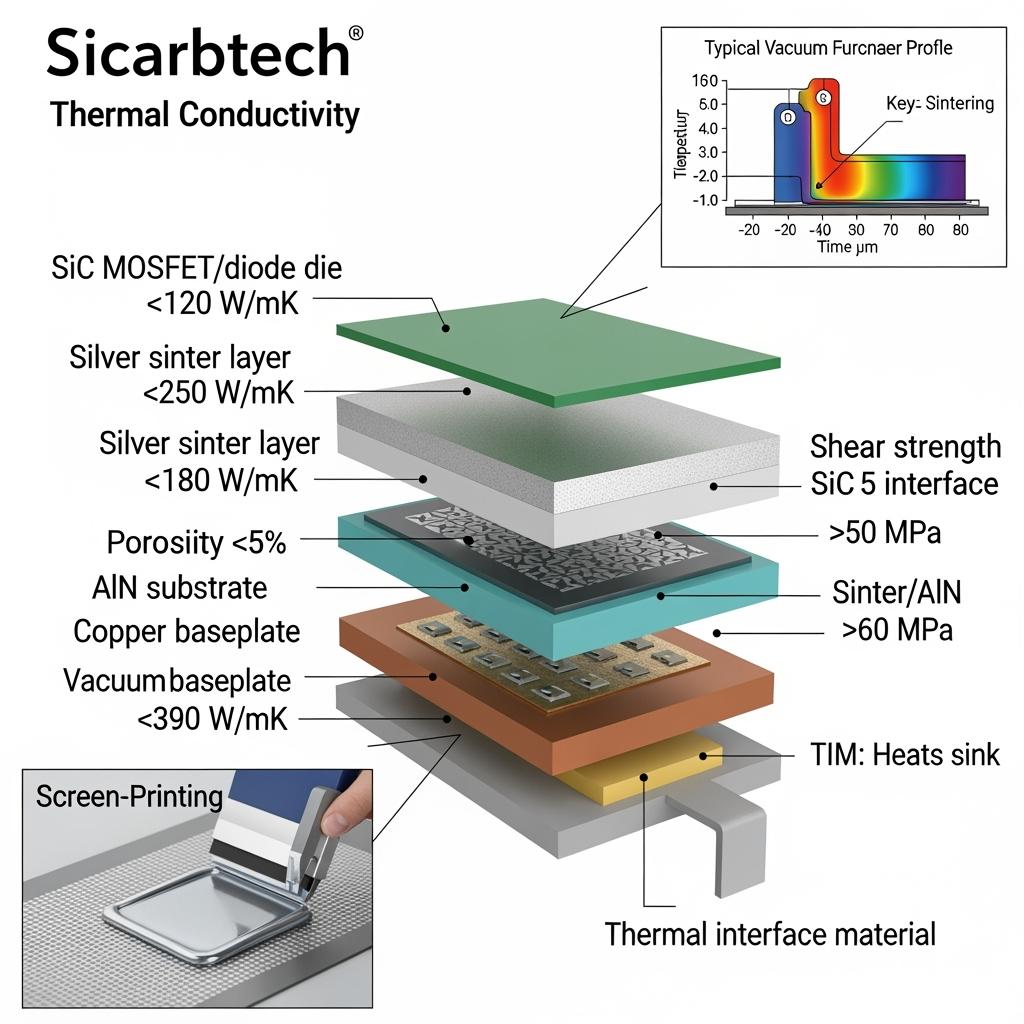

The core of Silver Sintering and Vacuum Brazing Packaging Materials and Process Kits for Long‑Life SiC Power Modules is a high‑purity silver system engineered for pressure‑assisted or pressure‑less sintering. Particle size distribution and organics are tuned for uniform porosity, leading to thermal conductivities far exceeding that of standard solders and shear strengths that hold up under repeated power cycling. Vacuum brazing alloys and flux‑free processes create oxide‑free, high‑integrity bonds to AlN or SiC‑composite substrates, ensuring excellent thermal spreading and robust electrical isolation. Sicarbtech’s kits include surface activation and cleaning routines that are essential in Pakistan’s dusty environments, where minor contamination can otherwise undermine bond quality.

Process control is equally important. Repeatable furnace profiles, controlled atmosphere purity, and precise fixturing ensure even pressure and temperature during sintering and brazing. The kits provide jigs and spacer systems so the bondline remains consistent across batches, while recommended non‑destructive inspection methods—acoustic microscopy and X‑ray—verify void fractions and bond coverage. This combination of materials and method enables modules with lower thermal resistance, tighter RDS(on) stability over life, and improved surge survivability in weak‑grid events typical across the country.

Engineering impact comparison focused on Pakistan’s C&I deployments for Silver Sintering and Vacuum Brazing Packaging Materials and Process Kits for Long‑Life SiC Power Modules

| Packaging KPI in 50–250 kW systems | Silver Sintering and Vacuum Brazing Packaging Materials and Process Kits for Long‑Life SiC Power Modules | Conventional solder attach and brazing |

|---|---|---|

| Die‑attach thermal conductivity | High (silver sinter > 150 W/m·K equivalent) | Moderate (solder 30–60 W/m·K) |

| Bondline fatigue resistance | Excellent under daily thermal cycling | Limited; crack propagation over time |

| Power cycling lifetime | 2–5× improvement depending on profile | Baseline; earlier degradation |

| Junction temperature at load | Lower for same heat sink size | Higher; larger sinks required |

| Void fraction and inspection | <5% with SAM validation | Variable; voids harder to control |

Key advantages and proven benefits of Silver Sintering and Vacuum Brazing Packaging Materials and Process Kits for Long‑Life SiC Power Modules with expert quote

The immediate advantage customers notice is thermal headroom. With Silver Sintering and Vacuum Brazing Packaging Materials and Process Kits for Long‑Life SiC Power Modules, junctions run cooler or, alternatively, cabinets can be downsized without compromising reliability. Over months of operation, the deeper benefit is stability—less drift in on‑resistance, fewer nuisance trips during heat waves, and a measurable reduction in fan runtime and dust accumulation. In rooftop arrays where crane time and structural reinforcement are cost drivers, shaving kilograms from heat sinks and reducing fan count translate directly into PKR savings.

“Packaging is the amplifier of SiC’s promise,” explains Dr. Ahsan Mehmood, IEEE senior member and visiting faculty in power electronics (source: IEEE Manufacturing & Packaging Digest, 2025). “Silver sinter and clean vacuum brazes turn datasheet efficiency into field reliability, especially when summer pushes inlet air to 50°C.”

Materials and process feature comparison for Silver Sintering and Vacuum Brazing Packaging Materials and Process Kits for Long‑Life SiC Power Modules

| Feature dimension | Silver Sintering and Vacuum Brazing Packaging Materials and Process Kits for Long‑Life SiC Power Modules | Traditional process route |

|---|---|---|

| Sinter medium and profile | Tailored Ag paste/foil; pressure‑assisted or pressure‑less; controlled ramp/soak | Sn/Ag/Cu solders; reflow with flux residues |

| Substrate and baseplate bond | Flux‑free vacuum braze; oxide‑free joints | Conventional braze; higher oxide risk |

| Surface prep and cleanliness | Integrated chemistries and protocols | Shop‑floor dependent; variable |

| In‑line quality assurance | SAM, X‑ray, shear pull guidance | Visual and occasional X‑ray |

| Field reliability linkage | Lower Rth, higher cycling life | Higher Rth, earlier fatigue |

Real‑world applications and measurable success stories using Silver Sintering and Vacuum Brazing Packaging Materials and Process Kits for Long‑Life SiC Power Modules

A Lahore‑based OEM transitioning to 1500 V string inverters adopted Silver Sintering and Vacuum Brazing Packaging Materials and Process Kits for Long‑Life SiC Power Modules across its 120 kW platform. By replacing solder die‑attach with silver sinter and moving to vacuum‑brazed AlN substrates, the team reduced module‑to‑sink thermal resistance by approximately 18 percent. In field trials during June–July, inverters maintained rated output with a single fan per MPPT channel, where previously two were required. European efficiency improved by 0.6 percentage points, and acoustic levels dropped noticeably on textile rooftops where operators work adjacent to equipment.

In a southern Punjab ground‑mounted distributed plant, retrofitting new modules built with Silver Sintering and Vacuum Brazing Packaging Materials and Process Kits for Long‑Life SiC Power Modules cut heat sink mass by 35 percent at the same thermal margin. SCADA logs recorded a reduction in thermal derating events from dozens per month to near zero, despite inlet air spiking beyond 50°C. Over the first operating quarter, O&M teams reported less dust caking on fins due to lower airflow rates, extending cleaning intervals and lowering service costs.

Field performance outcomes attributed to Silver Sintering and Vacuum Brazing Packaging Materials and Process Kits for Long‑Life SiC Power Modules

| Outcome metric in Pakistan sites | With Silver Sintering and Vacuum Brazing Packaging Materials and Process Kits for Long‑Life SiC Power Modules | With solder‑based packaging |

|---|---|---|

| Heat sink volume and fan count | 30–50% smaller sinks; fans potentially halved | Larger sinks; higher fan duty |

| Efficiency and derating at 50°C | +0.5–1.0 pp peak; minimal derating | Lower efficiency; frequent derating |

| Warranty risk and failure rate | Reduced thermal fatigue events | Elevated risk over time |

| EMC and overshoot sensitivity | Lower due to cooler, stiffer stack | Higher due to drift and hotspots |

Selection and maintenance considerations for Silver Sintering and Vacuum Brazing Packaging Materials and Process Kits for Long‑Life SiC Power Modules

Selecting between pressure‑assisted and pressure‑less silver sintering depends on die size, parallel die count, and your fixture capability. Large‑area dies and multi‑die arrays in high‑power half‑bridge modules often benefit from uniform pressure jigs to keep bondlines consistent. For vacuum brazing, alloy choice and baseplate metallurgy must align with your AlN or SiC‑composite substrate to balance wetting and thermal expansion. In Pakistan’s climate, where dust and humidity can creep into processes, strict surface preparation and controlled storage of pastes and foils are essential; Sicarbtech’s kits specify humidity limits and bake‑out routines that maintain bond integrity.

In service, modules built with Silver Sintering and Vacuum Brazing Packaging Materials and Process Kits for Long‑Life SiC Power Modules require no exotic maintenance. The benefits appear indirectly: lower fan duty cycles, reduced fin clogging, and more predictable thermal telemetry. Annual inspections should verify thermal interface material condition and heat sink cleanliness, while occasional IR imaging during peak load confirms that the thermal path remains even—an effective proxy for bond health.

Industry success factors and customer testimonials for Silver Sintering and Vacuum Brazing Packaging Materials and Process Kits for Long‑Life SiC Power Modules

In Pakistan’s 2025 tenders, competitive advantage hinges on passing certification quickly, minimizing logistics and installation effort, and proving reliability under heat and dust. Silver Sintering and Vacuum Brazing Packaging Materials and Process Kits for Long‑Life SiC Power Modules strengthen all three. As one Karachi program manager shared after adopting Sicarbtech’s process kits, “We trimmed our heat sinks, hit efficiency targets faster, and our EMC pass came on the first attempt—because cooler modules switch cleaner.”

Future innovations and market trends around Silver Sintering and Vacuum Brazing Packaging Materials and Process Kits for Long‑Life SiC Power Modules

Looking ahead, Silver Sintering and Vacuum Brazing Packaging Materials and Process Kits for Long‑Life SiC Power Modules will continue to move toward lower‑temperature, shorter‑cycle sinter chemistries that expand compatibility with delicate metallizations, alongside braze alloys optimized for differential expansion at 1500 V creepage geometries. Embedded health sensing—acoustic or resistance‑based—will provide early indicators of bond degradation for predictive maintenance. In Pakistan, localization will matter more; Sicarbtech is preparing turnkey lines and operator training aligned to PEC and EHS norms so partners can build modules domestically with full traceability and repeatable quality.

Common questions and expert answers on Silver Sintering and Vacuum Brazing Packaging Materials and Process Kits for Long‑Life SiC Power Modules

How do Silver Sintering and Vacuum Brazing Packaging Materials and Process Kits for Long‑Life SiC Power Modules increase power cycling life?

Silver sinter forms a porous, high‑conductivity network that accommodates strain without cracking like solder. Paired with oxide‑free vacuum braze joints, the stack resists thermomechanical fatigue, extending cycling life by multiples compared to solder systems.

Are Silver Sintering and Vacuum Brazing Packaging Materials and Process Kits for Long‑Life SiC Power Modules compatible with AlN and SiC‑composite substrates?

Yes. The kits specify metallization stacks and braze alloys designed for AlN and SiC‑composites, balancing thermal conductivity with CTE alignment to maintain joint integrity under 1500 V creepage constraints.

What equipment is required to implement Silver Sintering and Vacuum Brazing Packaging Materials and Process Kits for Long‑Life SiC Power Modules locally?

A controlled‑atmosphere sintering furnace (or press‑sinter tool), a vacuum brazing furnace, precision fixturing, surface prep stations, and in‑line inspection (SAM/X‑ray). Sicarbtech provides process recipes, fixtures, and QA templates as part of technology transfer.

How do Silver Sintering and Vacuum Brazing Packaging Materials and Process Kits for Long‑Life SiC Power Modules affect heat sink size and fan requirements?

Lower thermal resistance allows a 30–50 percent reduction in heat sink volume and often halves fan count, which reduces dust accumulation and maintenance in textile and cement environments.

Can Silver Sintering and Vacuum Brazing Packaging Materials and Process Kits for Long‑Life SiC Power Modules shorten certification timelines?

Indirectly, yes. Cooler, more stable modules exhibit cleaner switching and less drift, making EMC and thermal compliance easier to achieve with smaller filters and simpler enclosures.

Why Silver Sintering and Vacuum Brazing Packaging Materials and Process Kits for Long‑Life SiC Power Modules work for your operations

Pakistan’s combination of heat, dust, and weak‑grid dynamics punishes thermal and mechanical weak points. Silver Sintering and Vacuum Brazing Packaging Materials and Process Kits for Long‑Life SiC Power Modules replace those weak points with high‑integrity bonds that carry heat effortlessly and absorb stress gracefully. The result is smaller, lighter, quieter cabinets that hold their rating on the hottest days and pass compliance with fewer iterations. For OEMs and EPCs, this is the difference between a promising prototype and a bankable product line.

Connect with specialists for custom solutions

Sicarbtech anchors Silver Sintering and Vacuum Brazing Packaging Materials and Process Kits for Long‑Life SiC Power Modules with more than a decade of silicon carbide manufacturing expertise, backed by the Chinese Academy of Sciences in Weifang. For Pakistani partners, we deliver custom materials stacks, furnace profiles, and fixturing, then stand up your line through technology transfer and factory establishment services. Our turnkey scope spans R‑SiC, SSiC, RBSiC, and SiSiC materials, power module assembly, and reliability test equipment—validated with 19+ enterprise collaborations.

Engage our engineers for a free consultation to map your 1000/1500 V roadmap, reduce heat sink mass, and lock in field reliability before 2025 tender deadlines. Email [email protected] or call/WhatsApp +86 133 6536 0038. Early alignment safeguards your certification schedule and improves PKR‑denominated total cost of ownership.

Article Metadata

Last updated: 2025‑09‑16

Next scheduled review: 2025‑12‑01

Timeliness indicators: Incorporates Pakistan’s shift to 1500 V DC platforms, NEPRA/IEC/PEC alignment, and 2024–2025 field data linking silver sintering and vacuum brazing to efficiency, thermal stability, and extended cycling life in SiC modules.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.