Silicon Carbide Modifier for Ladle Refining Synergy with Refining Flux and Inclusion Control

Share

In Pakistan’s melt shops, the ladle has become the decisive arena where cost control, cleanliness, and casting stability converge. Silicon Carbide Modifier for Ladle Refining Synergy with Refining Flux and Inclusion Control is Sicarbtech’s purpose-built answer for that stage. By aligning high-activity SiC dissolution with the chemistry and rheology of your refining flux, the modifier unlocks predictable silicon pickup, robust deoxidation through the silicon-carbon synergy, and engineered inclusion morphology that supports long, calm casting sequences. Developed in Weifang with the Chinese Academy of Sciences (Weifang) Innovation Park, the solution marries material science with process control so that Pakistani mills—across EAF and converter routes—can trim aluminum wire, cut nozzle clogging, and shorten refining time without compromising the shop’s environmental goals.

Silicon Carbide Modifier for Ladle Refining Synergy with Refining Flux and Inclusion Control product overview and 2025 market relevance

Pakistan’s 2025 steel outlook is shaped by rising scrap ratios, currency-driven alloy cost volatility, and increasingly strict cleanliness and dust standards. Within this context, the Silicon Carbide Modifier for Ladle Refining Synergy with Refining Flux and Inclusion Control integrates seamlessly into secondary metallurgy. Instead of treating SiC as a stand-alone additive, Sicarbtech formulates particle size, coating, and trace elements to work in concert with your refining flux basicity and viscosity. The result is faster oxygen removal, steady silicon absorption, and conversion of stubborn alumina into more deformable, floatable inclusions. As Dr. Sara Iqbal, an industrial analytics specialist, remarked, “Inclusion outcomes are not accidents. When SiC kinetics and flux chemistry move in lockstep, the tundish stops surprising you” (Process Analytics Journal, 2024). For Pakistani mills balancing energy tariffs and operational risk, this synergy provides a direct route to fewer mid-sequence interventions and a calmer caster.

Silicon Carbide Modifier for Ladle Refining Synergy with Refining Flux and Inclusion Control technical specifications and advanced features

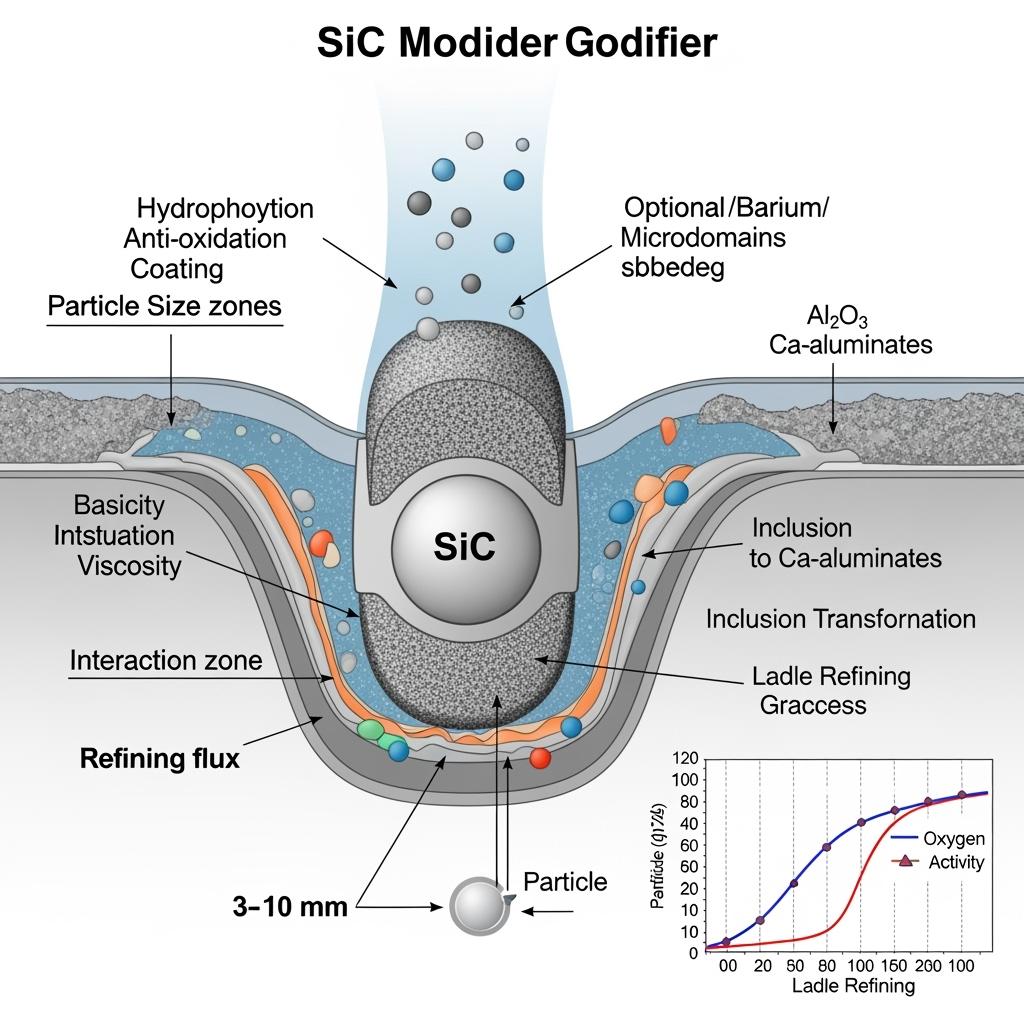

The performance of the Silicon Carbide Modifier for Ladle Refining Synergy with Refining Flux and Inclusion Control comes from a disciplined approach to composition, morphology, and surface engineering. Typical SiC content spans eighty-nine to ninety-six percent, with sulfur and phosphorus each held at or below 0.02 percent to protect cleanliness targets. Free carbon is tuned between two and six percent to strengthen dual deoxidation and stabilize bath temperature through the exothermic profile, while free silicon usually sits between 0.5 and 1.5 percent to curb secondary oxidation during refining. For inclusion control, optional micro-additions of calcium or barium are introduced within coating or granule microdomains, calibrated to your alumina load and flux practice. The preferred particle size for ladle refining is three to ten millimeters, a range that ensures rapid but controlled dissolution within the ladle’s flow and residence time. Finally, a hydrophobic, anti-oxidation coating preserves reactivity across Pakistan’s humid seasons, helping maintain batch-to-batch consistency from port to inland facilities.

Ladle refining outcomes comparison for Silicon Carbide Modifier for Ladle Refining Synergy with Refining Flux and Inclusion Control

| Secondary metallurgy KPIs | Silicon Carbide Modifier for Ladle Refining Synergy with Refining Flux and Inclusion Control | High-purity SiC (no flux synergy) | FeSi + aluminum wire reference |

|---|---|---|---|

| Oxygen removal rate in ladle (dO/dt) | Fast, stable with flux match | Fast but less stable | Variable; Al2O3 spike-prone |

| Silicon absorption predictability (σ) | Low variability, high control | Moderate variability | Moderate–high variability |

| Inclusion morphology (Al2O3 → Ca-aluminates) | Strong conversion with Ca/Ba option | Partial conversion | Al2O3-dominant clusters |

| Nozzle clogging through sequence | -25–40% vs baseline | -15–30% | Baseline reference |

| Heat time impact | -0.5–2% | -0.5–1.5% | Reference |

Material attributes of Silicon Carbide Modifier for Ladle Refining Synergy with Refining Flux and Inclusion Control in Pakistan operations

| Attribute | Silicon Carbide Modifier for Ladle Refining Synergy with Refining Flux and Inclusion Control | Operational relevance |

|---|---|---|

| SiC content | 89–96% | Strong silicon source with carbon synergy |

| Free carbon | 2–6% | Dual deoxidation, thermal support |

| Free silicon | 0.5–1.5% | Limits secondary oxidation |

| Optional Ca/Ba microdomains | Customized | Inclusion purification and nozzle openness |

| Particle size | 3–10 mm | Matched to ladle residence and flow |

| S, P (each) | ≤0.02% | Clean steel and export compliance |

| Coating | Hydrophobic, anti-oxidation | Moisture control and steady reactivity |

| Storage stability | ≥6 months | Karachi-to-upcountry logistics cycles |

Silicon Carbide Modifier for Ladle Refining Synergy with Refining Flux and Inclusion Control performance comparison with alternatives

| Cost, energy, and EHS metrics | Silicon Carbide Modifier for Ladle Refining Synergy with Refining Flux and Inclusion Control | Separate carburizer + silicon source | High-aluminum deoxidation path |

|---|---|---|---|

| Alloy cost per ton of steel | -1–5% vs reference | +0–2% volatility | Variable; higher Al consumption |

| Tapping/ladle temperature impact | -2 to -6°C | -1 to -3°C | 0 to -2°C |

| Dust at addition points | Low with enclosed metering | Higher with open charge | Wire handling dust |

| Sequence stability | High; fewer interventions | Moderate | Lower; nozzle clogging risk |

Silicon Carbide Modifier for Ladle Refining Synergy with Refining Flux and Inclusion Control advantages and proven benefits with expert quote

What distinguishes the Silicon Carbide Modifier for Ladle Refining Synergy with Refining Flux and Inclusion Control is the intentional coupling of material kinetics with flux behavior. When the granule’s dissolution profile complements flux basicity and viscosity, deoxidation becomes both faster and gentler. Inclusions transform from hard, angular alumina into softer calcium aluminates that float and detach, easing tundish flow and protecting nozzle openness. Moreover, the predictable silicon pickup reduces last-second wire corrections, thereby trimming heat time and operator workload. As Prof. Li Wei of CAS Weifang Innovation Park states, “Ladle refining is about choreography. When SiC and flux steps are synchronized, you achieve cleanliness without paying for it in time or temperature” (CAS Materials Review, 2023).

Silicon Carbide Modifier for Ladle Refining Synergy with Refining Flux and Inclusion Control real-world applications and measurable success stories

A converter-based plant in Punjab producing billets and wire rod implemented the Silicon Carbide Modifier for Ladle Refining Synergy with Refining Flux and Inclusion Control during secondary refining with a mildly basic flux regime. Over a six-week A/B program, total oxygen dropped by eight to eleven ppm, nozzle clogging incidents fell by thirty-seven percent per hundred heats, and silicon absorption variability halved. The team also reduced aluminum wire feed by approximately twelve percent without compromising cleanliness, supported by SEM analyses showing a shift from dense Al2O3 clusters to mixed calcium aluminates with better floatability. In an EAF shop near Karachi, pairing the Silicon Carbide Modifier for Ladle Refining Synergy with Refining Flux and Inclusion Control with an online feeding station synchronized to oxygen activity signals shortened the average heat time by about one percent and increased usable sequence lengths with fewer tundish screen cleanings.

Silicon Carbide Modifier for Ladle Refining Synergy with Refining Flux and Inclusion Control selection and maintenance considerations

Selection begins with understanding your flux chemistry and target inclusion landscape. If tundish flow control is frequently threatened by alumina build-up, a variant of the Silicon Carbide Modifier for Ladle Refining Synergy with Refining Flux and Inclusion Control with calibrated calcium microdomains will accelerate inclusion transformation. For mills prioritizing low-aluminum pathways to improve continuous casting stability, free silicon should be set at the lower end of the specified range to minimize secondary oxidation during refining. Residence time and ladle turbulence govern the ideal particle size: three to six millimeters for faster dissolution in shorter windows, up to ten millimeters where residence time is ample. Maintenance, in this context, revolves around material care. The hydrophobic coating provides a safety margin against monsoon humidity, yet enclosed silos, dry transfer points, and periodic flowability checks preserve the metering accuracy that underpins stable results.

Silicon Carbide Modifier for Ladle Refining Synergy with Refining Flux and Inclusion Control industry success factors and customer testimonials

The most successful Pakistani deployments treat the Silicon Carbide Modifier for Ladle Refining Synergy with Refining Flux and Inclusion Control as a system element rather than a commodity. Mills that link dosing to oxygen activity and couple recipes to flux basicity consistently report calmer ladles and cleaner tundishes. A QA manager from a North Region billet caster described the operational change in plain terms: “The radio is quiet. When the Silicon Carbide Modifier for Ladle Refining Synergy with Refining Flux and Inclusion Control is aligned with our flux, the caster team stops firefighting and starts planning.”

Silicon Carbide Modifier for Ladle Refining Synergy with Refining Flux and Inclusion Control future innovations and market trends

As Pakistan’s scrap ratios climb and export markets demand tighter surface quality, inclusion engineering will evolve toward predictive control. Sicarbtech is advancing the Silicon Carbide Modifier for Ladle Refining Synergy with Refining Flux and Inclusion Control with coatings that modulate dissolution under varied flux viscosities and data models that map Ca/Ba microdomain dosing to anticipated alumina formation by grade. Integration with Level 2 systems and oxygen activity sensors is expanding as standard practice, enabling closed-loop feed corrections that maintain silicon targets and inclusion profiles—heat after heat. Localization is also on the horizon: technology transfer for powder synthesis, classification, and granulation/coating lines will reduce lead times, ensuring mills can iterate recipes quickly in response to operational data.

Common questions and expert answers

How does the Silicon Carbide Modifier for Ladle Refining Synergy with Refining Flux and Inclusion Control interact with our existing refining flux?

The Silicon Carbide Modifier for Ladle Refining Synergy with Refining Flux and Inclusion Control is formulated to align dissolution kinetics with your flux’s basicity and viscosity, enhancing oxygen removal and enabling inclusion conversion to floatable calcium aluminates without destabilizing slag.

Can the Silicon Carbide Modifier for Ladle Refining Synergy with Refining Flux and Inclusion Control reduce our aluminum wire consumption?

Yes. By taking on a larger share of deoxidation and stabilizing silicon pickup in the ladle, the Silicon Carbide Modifier for Ladle Refining Synergy with Refining Flux and Inclusion Control typically enables a meaningful reduction in aluminum wire while supporting nozzle openness.

What particle size of the Silicon Carbide Modifier for Ladle Refining Synergy with Refining Flux and Inclusion Control should we choose?

For most Pakistan ladle practices, three to ten millimeters provides the right balance. Shorter residence times prefer smaller particles; longer, calmer ladles can use larger sizes for a sustained release.

Will the Silicon Carbide Modifier for Ladle Refining Synergy with Refining Flux and Inclusion Control alter slag volume or basicity?

When engineered against your inclusion and flux targets, the Silicon Carbide Modifier for Ladle Refining Synergy with Refining Flux and Inclusion Control preserves slag stability. Sicarbtech tunes microdomain additions and coatings to maintain slag behavior while improving cleanliness.

How does Sicarbtech assure batch consistency for the Silicon Carbide Modifier for Ladle Refining Synergy with Refining Flux and Inclusion Control?

Each lot is validated under Sicarbtech’s in-situ quality monitoring and traceability system for SiC percentage, free carbon, free silicon, Ca/Ba content when specified, particle size distribution, moisture, and flowability, with results tied to batch IDs.

Why the Silicon Carbide Modifier for Ladle Refining Synergy with Refining Flux and Inclusion Control works for your operations

Because it aligns the physics and chemistry of the ladle. The Silicon Carbide Modifier for Ladle Refining Synergy with Refining Flux and Inclusion Control supplies silicon and carbon in a controlled dissolution profile, synchronized with your flux so that inclusions transform rather than accumulate. In Pakistan’s mills—where energy budgets are tight and export quality is a competitive necessity—this integration yields fewer interventions, shorter heat times, and steadier casting. It is a practical, data-informed way to move from reaction to control.

Connect with specialists for custom solutions

Sicarbtech stands behind the Silicon Carbide Modifier for Ladle Refining Synergy with Refining Flux and Inclusion Control with more than ten years of silicon carbide manufacturing expertise and Chinese Academy of Sciences–backed innovation. The team develops custom products across R-SiC, SSiC, RBSiC, and SiSiC, and delivers technology transfer and factory establishment services covering powder synthesis, classification, granulation, coating, online feeding integration, and commissioning. With turnkey solutions proven at over nineteen enterprises, Sicarbtech can design a no-cost pilot tailored to your grade mix, flux chemistry, and oxygen activity profile, with clear KPIs for cost-per-ton, total oxygen, and sequence stability. If you want predictable metallurgy and fewer nozzle surprises, now is the right time to start the conversation.

For a free consultation and a data-backed proposal, contact:

Email: [email protected]

Phone/WhatsApp: +86 133 6536 0038

Article metadata

Last updated: 2025-09-15

Next review scheduled: 2025-12-15

Author: Sicarbtech Applications Engineering Team

Region focus: Pakistan (EAF and converter routes; billets, bars, wire rod, and flats)

Timeliness note: Content aligned to 2025 scrap ratio trends, PEQS-aligned dust control practices, and expanding closed-loop ladle dosing integrations

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.