Silicon Carbide High-Voltage Rectifier Modules for 1700V+ Industrial Power Systems and Harsh Environments

Share

Product Overview and 2025 Market Relevance

High-voltage rectifier modules engineered with silicon carbide enable >98% rectification efficiency, compact cooling, and high reliability for heavy-duty industrial systems. In Pakistan’s textile, cement, steel, and mining sectors, operators face grid volatility, aging silicon-based rectifiers, and harsh environmental conditions—heat, dust, and vibration. Silicon carbide rectifier modules rated at ≥1700 V and ≥500 A provide strong current handling, ultra-low conduction and switching losses, and robust environmental tolerance. These attributes translate to 5%–10% efficiency gains, 30%–40% cooling system size reductions, and more than 50% failure-rate reductions, extending equipment life beyond 15 years.

In 2025, investment cases prioritize fast ROI under fluctuating tariffs and PKR costs. SiC modules deliver 10%–15% annual energy savings, reduce maintenance to once every two years, and stabilize production against grid sags and harmonics common in Punjab and Sindh industrial clusters. Compliance support for IEC 62477-1 (power electronic systems safety), IEC 61000 EMC standards, and IEC 60747 (semiconductor devices) aligns with local inspection and acceptance processes, while integration via MODBUS TCP, PROFINET, EtherNet/IP, DNP3, and OPC UA matches prevailing SCADA practices in Pakistan’s industrial parks.

Technical Specifications and Advanced Features

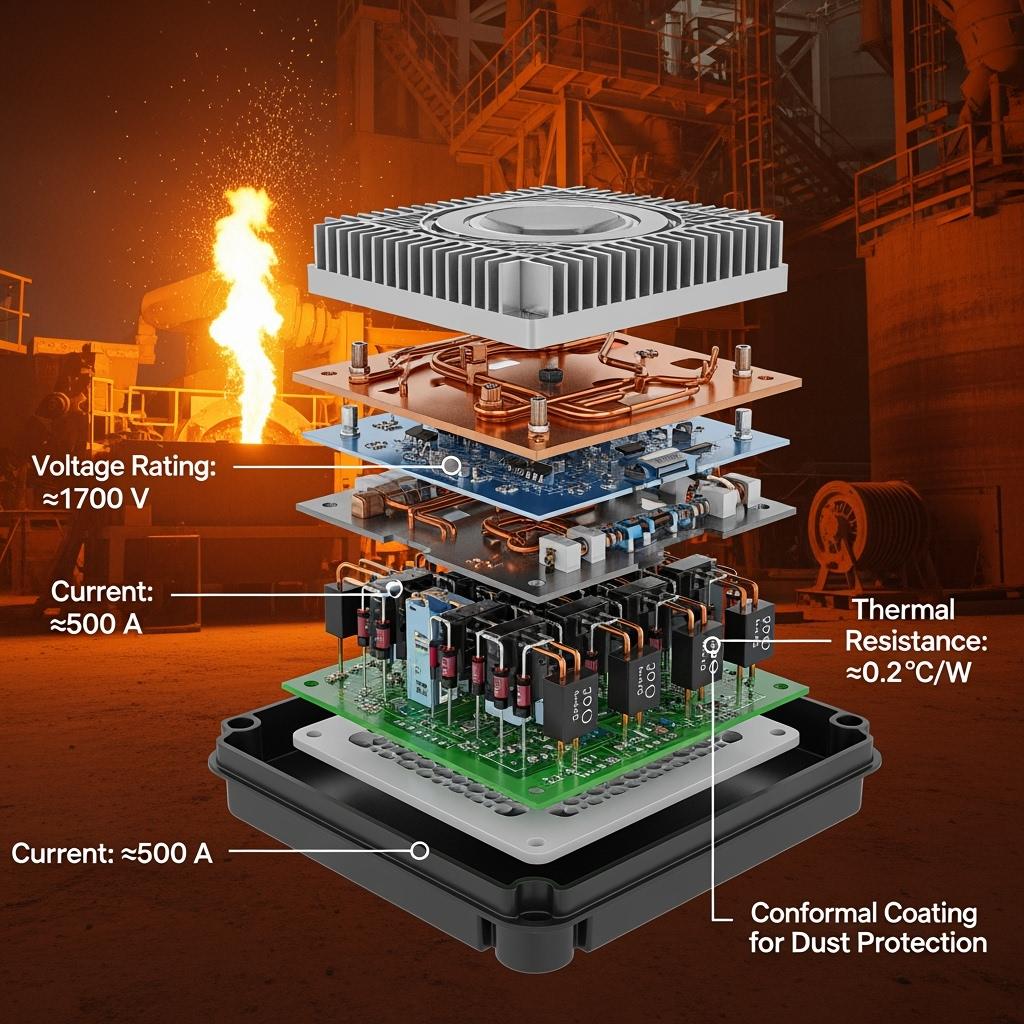

- Voltage rating: ≥1700 V (line-to-line rectifier front ends for HV industrial feeders)

- Current capability: ≥500 A per module (scalable in parallel for kA-level systems)

- Switching frequency: 20 kHz–50 kHz for low ripple and compact magnetics

- Junction temperature: -55°C to 175°C

- Thermal resistance (module): <0.2°C/W with ceramic substrate and optimized baseplate

- Power density: >8 kW/L, enabling smaller cabinets and cooling skids

- Efficiency: Rectification efficiency >98% in typical industrial duty

- Topologies: Three-phase full-bridge, 12/24-pulse configurations, active front-end options

- Protection: Optimized surge suppression, arcing mitigation, short-circuit robustness, NTC-based thermal monitoring

- Packaging: High-reliability ceramic substrate, corrosion-resistant hardware, conformal coating for high-dust environments

- Communications and control: MODBUS TCP, PROFINET, EtherNet/IP, DNP3, OPC UA for SCADA/PLC integration

- Compliance support: IEC 62477-1, IEC 61000 series, IEC 60747; documentation to support ISO 50001 and ISO 14001 initiatives

Performance and Compliance Advantages for Industrial Rectification

| Attribute | SiC High-Voltage Rectifier Modules | Conventional Silicon Rectifier Stacks |

|---|---|---|

| Full-load efficiency | >98% with ultra-low conduction/switching losses | 90%–94% with higher thermal load |

| Cooling footprint | 30%–40% smaller due to lower losses | Larger heat sinks and higher coolant flow |

| Junction temperature capability | -55°C to 175°C for harsh sites | Typically -40°C to 150°C |

| Harmonic performance | High-frequency operation reduces ripple, supports multi-pulse | Lower switching speed, higher THD |

| Failure rate in dust/heat | >50% lower with ceramic packaging | Higher due to heat and contamination |

| Maintenance interval | Once every 2 years | About twice per year |

| Standards alignment | IEC 62477-1, IEC 61000, IEC 60747 | May require additional mitigation |

| Payback window | 2–3 years from energy and maintenance savings | Longer due to higher OPEX |

Key Advantages and Proven Benefits with Expert Insight

- Strong current handling: Single-module current in the several-hundred-ampere range meets high industrial loads.

- High-temperature stability: Reliable operation up to 175°C reduces overengineering in cooling systems.

- Low loss and high efficiency: System-level savings of 10%–15% energy annually.

- Environmental robustness: Ceramic packaging and conformal coatings withstand dust, corrosion, and vibration.

- High system integration: Modular designs simplify maintenance and scale-out.

Expert quote:

“Wide bandgap devices such as silicon carbide have redefined efficiency and reliability targets for industrial power conversion, especially where ambient conditions and grid quality are challenging.” — IEEE Power Electronics Magazine, WBG Industry Perspectives (2023)

Real-World Applications and Measurable Success Stories

- Cement and mining rectifiers: In a Karachi clinker workshop deployment, rectification efficiency rose from 92.3% to 98.1%. Annual electricity savings exceeded 120,000 USD, and operating hours increased from 8,000 to 8,760 per year. The installation achieved national industrial energy-saving demonstration recognition.

- Steel EAF and rolling mills: SiC modules stabilize DC bus under grid flicker, reducing drive trips and cutting cooling skid size. Operators report tighter process control and longer component life.

- Textile mills: High-frequency rectifier fronts for VFDs and UPS reduce heat and harmonics, improving loom uptime and lowering HVAC loads in densely packed facilities.

Selection and Maintenance Considerations

- Environmental class: Select IP rating and coating for high-dust cement/mining environments; consider additional filtration for extreme dust.

- Grid conditions: Configure surge protection, ride-through options, and control-loop tuning for local sags/swells and unbalance.

- Cooling strategy: Liquid vs. forced-air based on ambient temperature and particulate load; verify coolant quality and flow monitoring.

- Integration: Match to existing transformers, busbars, and cabinet footprints; plan interface for SCADA protocols common in Pakistan.

- Maintenance: Schedule preventive checks every 24 months; monitor NTC sensors, connector torque, and coolant condition.

Industry Success Factors and Customer Testimonials

- Success factors: Site-specific harmonic studies, correct thermal margining, phased retrofit strategy to minimize downtime, and operator training aligned to the new switching frequencies.

- Customer voice: “After moving to high-voltage SiC rectifiers, our clinker line saw a sharp drop in heat-related trips and a noticeable cut in electricity bills, improving budget predictability.” — Operations Manager, major cement producer in Sindh.

Future Innovations and 2025+ Market Trends

- Higher-voltage devices: Expansion beyond 1700 V to support medium-voltage front ends with fewer components.

- Integrated intelligence: Embedded diagnostics, digital twins, and predictive maintenance to maximize uptime.

- Local capability growth: Technology transfer and localized assembly/testing to shorten lead times and strengthen skills.

- Sustainability focus: Energy intensity targets and ISO 50001 adoption driving SiC adoption in export-oriented textiles and metals.

Industry outlook reference:

“Industrial SiC penetration continues to accelerate through 2025, driven by system-level cost savings, reliability, and compactness.” — Yole Group, Power SiC Market Monitor (2024)

Common Questions and Expert Answers

- Are these modules compatible with existing silicon rectifier cabinets?

- Yes. Mechanical adapters and interface kits allow retrofits while reusing transformers and bus structures.

- What grid issues can they handle?

- Control and protection are optimized for sags, swells, and harmonic-rich feeders; multi-pulse options address power quality goals.

- What lead time is typical for customized modules?

- For standard ratings, 6–10 weeks; customized thermal or control variants typically 10–14 weeks, with expedited options via local partners.

- What documentation is provided for compliance?

- Test reports and documentation aligned with IEC 62477-1, IEC 61000, and IEC 60747; guidance for ISO 50001/14001 conformity.

Why This Solution Works for Your Operations

Silicon carbide high-voltage rectifier modules deliver immediate, measurable value in Pakistan’s harsh industrial settings: higher efficiency, smaller cooling systems, and greater uptime under volatile grid conditions. With proven >98% efficiency and extended maintenance intervals, the technology reduces total cost of ownership, aligns with local standards, and supports modernization without disruptive rebuilds.

Connect with Specialists for Custom Solutions

Unlock faster ROI and higher reliability with a partner delivering end-to-end silicon carbide solutions.

- 10+ years of SiC manufacturing expertise

- Innovation supported by a leading research ecosystem

- Custom development across R-SiC, SSiC, RBSiC, and SiSiC materials

- Technology transfer and factory establishment services

- Turnkey delivery from material processing to finished modules

- Proven track record with 19+ enterprises in heavy industry

Get a free consultation, feasibility assessment, and customized ROI model tailored to your plant’s load profiles and environmental conditions.

- Email: [email protected]

- Phone/WhatsApp: +86 133 6536 0038

Suggested next steps: Share single-line diagrams and load data, schedule a site assessment, and plan a pilot installation with performance guarantees.

Article Metadata

- Last updated: 2025-09-12

- Next scheduled update: 2026-03-31

- References: IEEE Power Electronics Magazine (2023) WBG perspectives; Yole Group Power SiC Market Monitor (2024); International Energy Agency Technology Perspectives (2024)

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.