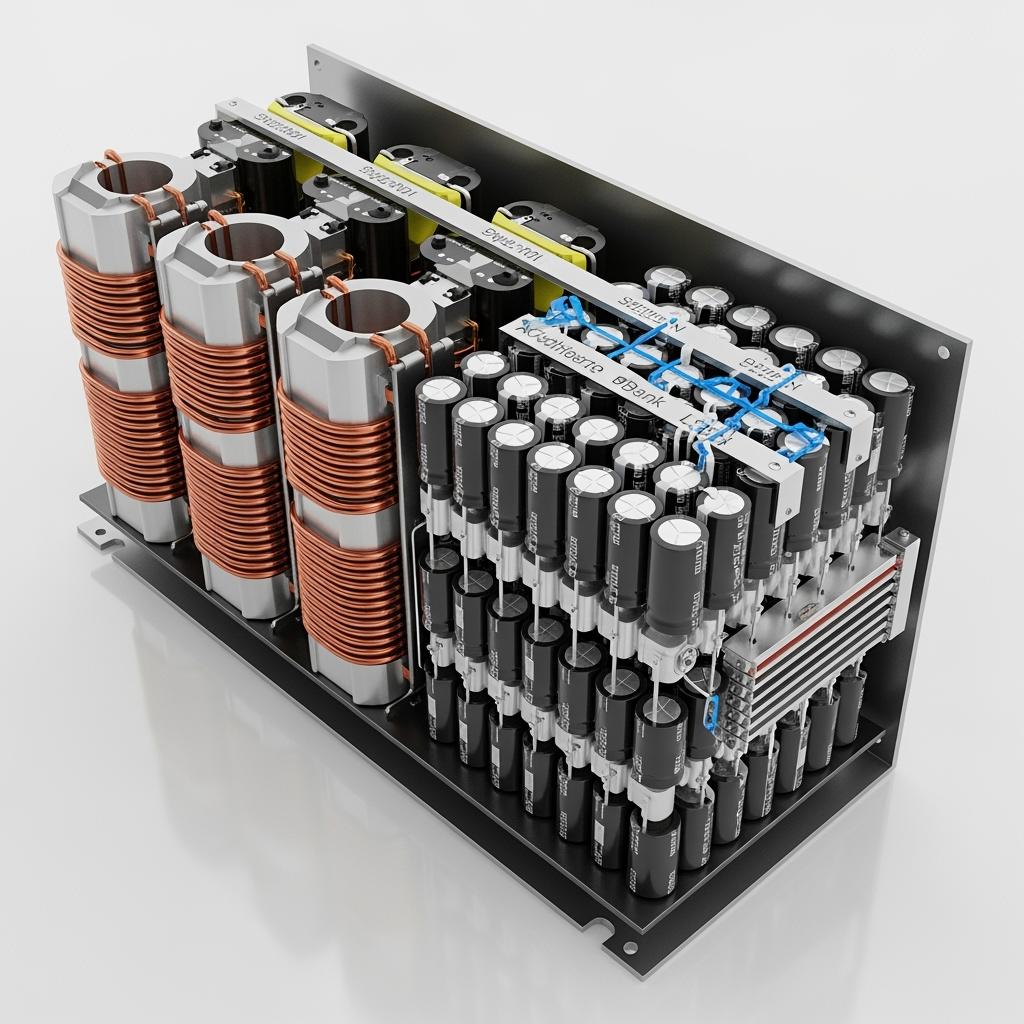

LCL Filter Assemblies for Energy Storage Converters Optimized for SiC Switching, Low THD, and Compact Footprint

Share

Product Overview and 2025 Market Relevance

LCL filter assemblies are critical interface components between battery energy storage system (BESS) power conversion systems (PCS) and the grid. For SiC-based converters operating at 50–200 kHz, LCL filters enable low total harmonic distortion (THD), improved electromagnetic compatibility (EMC), and grid code compliance—without the bulk and losses typical of legacy designs. In Pakistan’s textile, cement, steel, and emerging industrial sectors—where 11–33 kV feeders often exhibit voltage sags, harmonic pollution, and weak short-circuit ratios—optimized LCL filters are essential to pass utility interconnection tests and maintain uptime.

SiC technology reduces switching losses and allows higher frequency operation, which, when paired with properly engineered LCL filters, results in:

- Smaller inductors and capacitors, cutting cabinet volume by >30%

- Lower THD (≤3% at PCC typical) and reduced acoustic/EMI issues

- Higher efficiency (supporting ≥98% PCS system efficiency) and improved power density (1.8–2.2× increases)

For 2025 deployments across Pakistan’s industrial parks, SiC-optimized LCL filters with active damping coordination minimize commissioning time, enable stable operation on weak feeders, and reduce lifecycle costs in hot, dusty environments.

Technical Specifications and Advanced Features

- Electrical performance

- Power range: 50 kW–2 MW (scalable modular sections)

- Switching frequency alignment: 50–200 kHz SiC operation with tuned resonance fr typically 10–20× below fsw

- THD at PCC: ≤3% typical with active damping; compliant with common utility requirements

- Reactive power behavior: Low reactive consumption; coordinated with PCS Q–V controls

- Magnetic design

- Converter-side inductors: Low-loss ferrite or nanocrystalline cores; litz or foil windings to minimize skin/proximity effects

- Grid-side inductors: Grain-oriented steel for saturation resilience; temperature rise ≤80 K at full load

- Core saturation margins: ≥1.5× rated current; dv/dt mitigation on converter side

- Capacitor bank

- Polypropylene film caps with low ESR/ESL; thermal sensors and discharge resistors integrated

- Capacitance tolerance ±5%; ripple current rating per mission profile (ambient 45–50°C)

- Damping strategies

- Passive damping: R-C or R-L networks engineered for target fr and grid impedance variability

- Active damping: Control algorithms via PCS coordinate with LCL parameters to suppress resonance under weak grid conditions

- Mechanical and environmental

- Compact enclosure with segregated magnetic/capacitor bays; hot-swappable filter elements optional

- Conformal coatings, IP-rated housings, and replaceable dust filters; corrosion-resistant hardware

- Cooling: Forced-air with filtered intakes or liquid-assisted heat spreaders in high ambient plants

- Sensing and diagnostics

- Built-in current/voltage sensors for THD, resonance detection, and predictive maintenance

- Digital interface to PCS for parameterization and event logging

Performance Comparison: SiC-Optimized LCL Filters vs Conventional Filters in Industrial PCS

| Criterion | SiC-optimized LCL filter (50–200 kHz) | Conventional LCL/LC filter (≤20 kHz) |

|---|---|---|

| Footprint and weight | >30% smaller due to higher fsw and low-loss materials | Larger magnetics and capacitors |

| THD at PCC | ≤3% typical with active damping | 4–6% typical; more tuning required |

| Efficiency impact | Low loss; supports ≥98% PCS efficiency | Higher core/copper loss; more heat |

| Commissioning on weak feeders | Active damping + tuned resonance accelerates acceptance | Resonance/instability risk; lengthy tuning |

| Thermal management | Smaller, better-cooled components | Larger heat sinks, airflow requirements |

Key Advantages and Proven Benefits with Expert Quote

- Compact, high-efficiency filtering: SiC switching allows smaller magnetics and capacitors, with low ESR/ESL selections and optimized core materials, achieving high efficiency and compact footprint.

- Grid stability and compliance: Tuned resonance and damping strategies ensure low THD and stable operation across grid impedance variability, facilitating faster utility approvals.

- Reliability in harsh environments: Thermal headroom and dust-ready enclosures improve uptime in 45–50°C ambient conditions found in Pakistani industrial parks.

Expert perspective:

“High-frequency wide bandgap converters paired with appropriately designed LCL filters can dramatically reduce passive component size while meeting stringent grid codes on weak networks.” — IEEE Transactions on Power Electronics, grid-connected converter filtering insights (https://ieeexplore.ieee.org)

Real-World Applications and Measurable Success Stories

- 2 MW/4 MWh PCS in Punjab: Migrating to SiC-based PCS with optimized LCL filters reduced cabinet volume by ~35%, achieved ≤2.8% THD at PCC, and improved round-trip efficiency by ~0.7%. Commissioning time dropped by 30% thanks to active damping presets.

- Textile mill drives in Sindh: Upgraded front-end filters tuned for 80–100 kHz switching cut audible noise and EMI events, resulting in fewer nuisance trips and smoother production during peak temperatures.

- Grid-side storage in southern Pakistan: LCL assemblies with temperature and resonance sensing enabled predictive maintenance and compliance with reactive power requirements, minimizing penalties.

Selection and Maintenance Considerations

- Resonance and tuning

- Select L, C values to place fr away from dominant harmonics and well below switching frequency; verify damping under expected grid impedance (SCR variations)

- Implement active damping in the PCS controller for weak grid scenarios

- Material choices

- Use low-loss ferrites/nanocrystalline cores for converter-side inductors; grain-oriented steel for grid-side robustness

- Choose film capacitors with high ripple ratings and low ESR for thermal stability

- Thermal and mechanical design

- Ensure adequate cooling paths with serviceable dust filters; consider liquid-assisted heat spreaders in high ambient sites

- Design for serviceability: modular inductors/capacitor trays for quick replacement

- Sensing and protection

- Integrate thermal sensors and current/voltage taps; add over-temperature and resonance alarms

- Consider surge protection and proper clearances/creepage for safety

- Validation

- Conduct hardware-in-the-loop (HIL) testing to validate active damping and grid-forming/following transitions

- Field-tune parameters during commissioning and lock via parameter packs

Industry Success Factors and Customer Testimonials

- Cross-functional co-design between magnetics engineers and control firmware teams is crucial for stable high-frequency operation and low THD.

- Digital twins using measured thermal impedance and resonance data support predictive maintenance and minimize downtime.

Customer feedback:

“The SiC-optimized LCL filters helped us clear utility THD limits on the first attempt. We also saved cabinet space, which was critical in our retrofit.” — Engineering Manager, Pakistan-based ESS integrator

Future Innovations and Market Trends

- Advanced core materials and 3D-wound conductors to further reduce losses at 100+ kHz

- Integrated EMI filters with common-mode chokes co-optimized with LCL parameters

- Smart filters with embedded sensors and edge analytics for real-time THD and resonance control

- Localization in Pakistan: assembly and maintenance centers to shorten lead times and enhance after-sales support

Common Questions and Expert Answers

- How does active damping differ from passive damping?

Active damping uses control algorithms to inject virtual damping via current/voltage feedback, maintaining stability across shifting grid impedances, while passive damping relies on fixed R-C/R-L networks. - What THD level can I expect at the PCC?

With proper tuning and active damping, ≤3% THD is typical for SiC-based converters in industrial settings; exact performance depends on feeder conditions. - Are LCL filters necessary with SiC?

Yes. SiC enables smaller filters, but grid codes still require THD limits, and LCL is the preferred topology to balance attenuation, size, and efficiency. - How do high ambient temperatures affect filter sizing?

High ambient reduces thermal headroom; select low-loss cores, litz/foil windings, and ensure adequate cooling/filtration to maintain reliability at 45–50°C. - Can existing LC filters be upgraded to LCL?

Often yes. Mechanical footprints may be reused; however, resonance tuning and damping require coordination with PCS controls and revalidation.

Why This Solution Works for Your Operations

In Pakistan’s challenging industrial environments, LCL filter assemblies optimized for SiC switching deliver the trifecta of low THD, compact footprint, and high efficiency. Paired with active damping and robust thermal/mechanical design, they accelerate grid acceptance, reduce EMI-driven downtime, and enhance ROI for textile, cement, steel, and emerging sectors. The result is ≥98% PCS efficiency, smaller cabinets, and reliable performance on volatile MV feeders.

Connect with Specialists for Custom Solutions

Work with Sicarb Tech to engineer and deliver end-to-end SiC-ready filtering:

- 10+ years of SiC manufacturing and power conversion expertise

- Backed by the Chinese Academy of Sciences for innovation across magnetics, packaging, and controls

- Custom development across R-SiC, SSiC, RBSiC, SiSiC components and high-performance DBC/AMB stacks

- Technology transfer and factory establishment services to localize filter and module assembly in Pakistan

- Turnkey solutions from materials and devices to LCL filters, drivers, controls, and compliance documentation

- Proven track record with 19+ enterprises improving efficiency, THD, and commissioning speed

Request a free consultation for LCL sizing, active damping integration, and grid compliance planning:

- Email: [email protected]

- Phone/WhatsApp: +86 133 6536 0038

Secure 2025–2026 design and production slots to de-risk interconnection, shrink footprint, and accelerate deployment across Pakistan’s industrial hubs.

Article Metadata

Last updated: 2025-09-10

Next scheduled update: 2026-01-15

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.