Vacuum Sintering Equipment for Silicon Carbide Devices and Ag-Stack Interconnects with High Reliability

Share

Product Overview and 2025 Market Relevance

Vacuum sintering equipment is a cornerstone of robust silicon carbide (SiC) device packaging, enabling high-reliability Ag-based interconnects and die attaches that withstand harsh thermal cycling. In Pakistan’s textile, cement, steel, and emerging industrial sectors, battery energy storage system (BESS) PCS and MV inverters face 45–50°C ambient temperatures, dust, and grid volatility on 11–33 kV feeders. Under these conditions, traditional solder attaches fatigue, raising thermal resistance and jeopardizing uptime. Vacuum sintering of silver (Ag) paste, preforms, or nano-Ag films creates a near-porosity-free metallurgical bond with exceptional thermal conductivity and creep resistance, directly improving converter efficiency, power density, and lifetime.

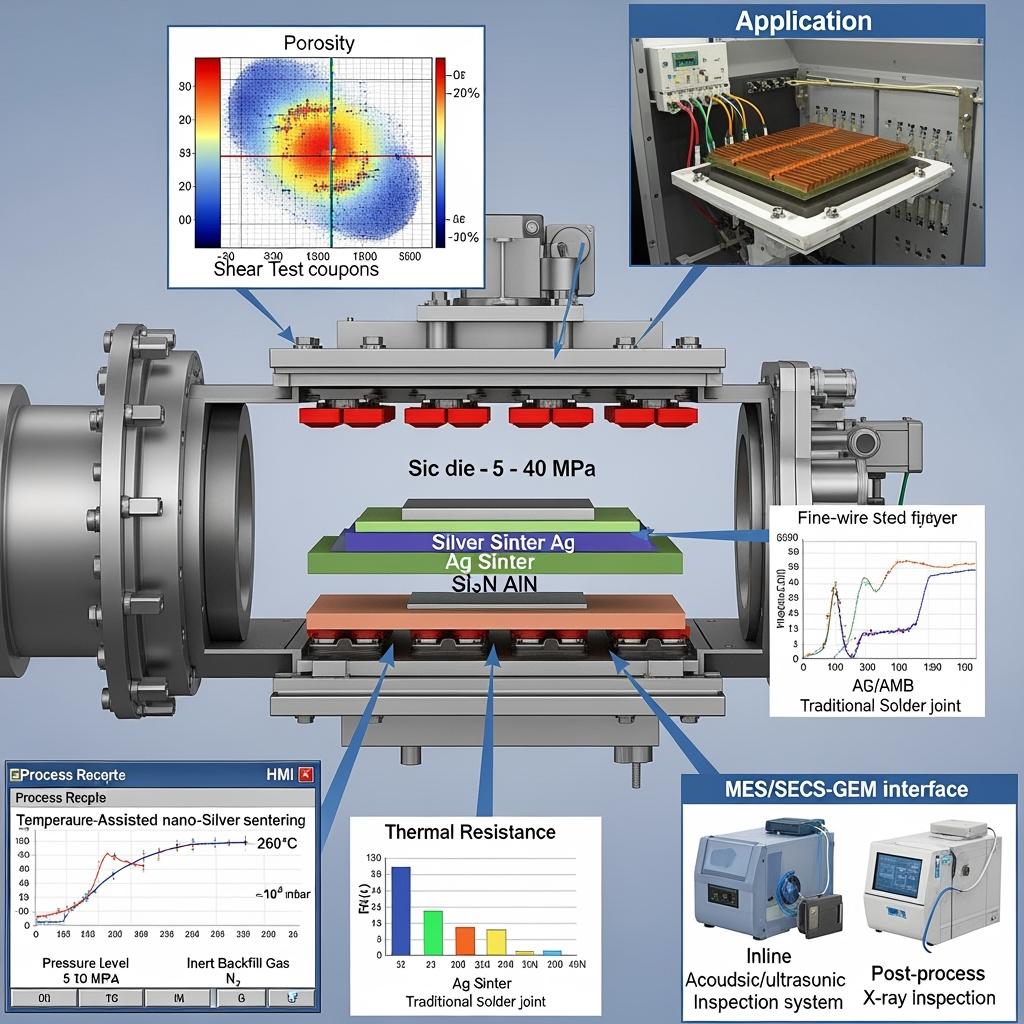

As SiC switching frequencies rise to 50–200 kHz for compact magnetics and ≥98% system efficiencies, junction temperature swings (ΔTj) increase. Vacuum sintering equipment provides the precise pressure, temperature, and atmosphere control needed to form high-strength Ag stacks between SiC dies, DBC/AMB substrates (Si3N4/AlN), and baseplates or cold plates. Key 2025 drivers for Pakistan include:

- Reliability uplift: Ag-sinter interconnects help reach MTBF targets near 200,000 hours, even with dusty, hot environments that constrain cooling.

- Efficiency and density: Lower thermal resistance reduces junction temperatures, enabling smaller heat sinks and 1.8–2.2× power density improvements.

- Localization: Establishing in-country sintering capability reduces lead times, aligns with government industrial upgrading, and strengthens after-sales support.

Technical Specifications and Advanced Features

- Process capability

- Temperature range: 150–300°C for pressure-assisted nano-Ag; up to 400–500°C options for specialized Ag systems

- Pressure control: 5–40 MPa programmable, uniform across platen area with real-time feedback

- Atmosphere: High vacuum (<10^-3 mbar) with inert (N2/Ar) backfill; low O2 ppm control to prevent oxidation

- Alignment and planarity: <20 µm planarity across 200×200 mm fixtures; low warp clamping options

- Thermal profiles: Multi-step ramps/soaks; controlled cool-down to mitigate residual stress

- Materials and stacks

- Ag pastes, nano-Ag films, and preforms; compatible with Ni/Ag/Au finishes on Cu; supports DBC/AMB (Si3N4/AlN) substrates and Cu/Mo baseplates

- Multi-level stacks for die attach plus substrate-to-baseplate bonding

- Quality assurance and metrology

- Inline displacement/pressure trace logging; lot-based data records

- Post-process non-destructive evaluation (C-SAM/ultrasonic), X-ray for voids, shear/pull test stations

- Rth-jc extraction workflows; thermal impedance mapping for digital twins

- Throughput and automation

- Batch and semi-continuous models; changeover kits for different module formats

- Robotic loading options; FOUP/SMIF compatibility for clean handling

- SECS/GEM and OPC-UA connectivity; recipe management and SPC dashboards

- Safety and maintenance

- Over-pressure/over-temp interlocks; vacuum breach detection

- Graphite hot-zone service kits; calibration routines for pressure and thermocouples

Performance Comparison for SiC Module Interconnects in Harsh Industrial Environments

| Criterion | Ag-based vacuum sintering (pressure-assisted) | High-lead or SAC solder attach |

|---|---|---|

| Thermal conductivity of joint | High (~150–250 W/m·K equivalent) | Moderate (40–70 W/m·K) |

| Power cycling endurance (ΔTj) | Excellent; minimal creep fatigue | Limited by solder creep/void growth |

| Operating temperature capability | Stable to 175°C junction | Derating needed at high Tj |

| Void rate and bondline quality | Very low porosity with process control | Higher void risk; pump-out over life |

| Impact on system size | Enables smaller heat sinks/cold plates | Larger cooling required |

Key Advantages and Proven Benefits with Expert Quote

- Lifetime reliability: Ag-sintered joints resist creep and maintain low thermal resistance across wide ΔTj cycles, critical for 50–200 kHz SiC converters operating in 45–50°C ambient temperatures.

- Efficiency and footprint: Reduced Rth-jc and uniform heat spreading lower heatsink/cold plate mass, improving PCS efficiency to ≥98% and shrinking cabinet volume by >30%.

- Process consistency: Vacuum plus controlled pressure delivers repeatable bondlines, enabling tighter parametric distributions and faster product ramp.

Expert perspective:

“Pressure-assisted silver sintering provides superior thermal and mechanical reliability compared to solder, making it the preferred interconnect for high-temperature, high-cycling SiC power modules.” — IEEE Power Electronics Magazine, packaging reliability insights (https://ieeexplore.ieee.org)

Real-World Applications and Measurable Success Stories

- 2 MW/4 MWh BESS in Punjab: Transitioning from solder to Ag-sintered die and substrate attaches reduced junction temperatures by ~10–14°C at full load. System efficiency rose to 98.2%, and cooling assembly volume dropped by ~35%, improving uptime during peak summer heat.

- Industrial drives in Sindh textile mills: Ag-sinter joints eliminated recurrent solder fatigue failures under frequent start/stop cycles. Mean time between service calls improved by >25%, lowering maintenance costs.

- MV inverter pilot in southern Pakistan: Ag-sintered DBC-to-baseplate reduced thermal drift across phases, enabling higher switching frequency and smaller LCL filters while meeting utility FRT and reactive power requirements on the first pass.

Selection and Maintenance Considerations

- Stack design

- Choose Si3N4-DBC for maximum cycling robustness; consider AlN-DBC for peak heat flux with managed cycling.

- Specify metallization compatible with Ag (Ni/Ag or Ni/Au finishes) and verify wettability.

- Process parameters

- Optimize temperature/pressure/soak to meet bondline thickness targets (e.g., 20–50 µm) and low porosity.

- Use cLAD/graphite tooling to maintain planarity and uniform pressure; monitor displacement profiles.

- Inspection and metrology

- Deploy C-SAM for void detection, X-ray for coverage, and shear tests per IPC/JEDEC guidelines.

- Extract thermal impedance for digital twin models and predictive maintenance.

- Environmental readiness

- Consider conformal coatings and corrosion-resistant finishes for humid, dusty sites; ensure filter maintenance plans for cooling.

- Supply chain and localization

- Source Ag pastes/preforms with stable rheology; implement cold-chain storage where required.

- Plan operator training and preventive maintenance to ensure high equipment uptime.

Industry Success Factors and Customer Testimonials

- Cross-functional collaboration between packaging, thermal, and control teams shortens time-to-commissioning and improves field reliability.

- SPC on pressure, temperature, and vacuum improves lot-to-lot consistency, reducing rework and warranty risk.

Customer feedback:

“Adopting vacuum Ag sintering eliminated our solder fatigue failures and shaved several degrees off junction temperatures, letting us pass utility tests without upsizing cooling.” — Engineering Lead, Pakistan-based PCS manufacturer

Future Innovations and Market Trends

- Lower-temperature nano-Ag systems for sensitive substrates while retaining high reliability

- Inline porosity metrology and AI-driven parameter tuning to maximize yield

- Copper-sinter and hybrid Ag/Cu stacks for cost reduction without compromising performance

- Localization programs in Pakistan to establish module packaging lines with vacuum sintering and inline inspection

Common Questions and Expert Answers

- What pressure and temperature are typical for Ag sintering?

Pressure-assisted sintering commonly uses 5–30 MPa and 200–260°C for nano-Ag pastes; recipes vary with paste type and stack. - How does Ag sinter compare to solder in cycling tests?

Ag-sinter joints show markedly improved resistance to creep and crack growth, sustaining high ΔTj cycles where solders fatigue. - Is vacuum mandatory?

A controlled vacuum with inert backfill minimizes oxidation and improves densification, delivering low-void bondlines and repeatability. - Can we retrofit existing module designs?

Yes. Many solder-based footprints can be adapted; verify metallization compatibility and re-qualify thermal/mechanical performance. - What inspections are essential?

C-SAM, X-ray, bondline thickness checks, shear tests, and thermal impedance extraction provide a comprehensive quality picture.

Why This Solution Works for Your Operations

Vacuum sintering for Ag-stack interconnects converts SiC’s theoretical advantages into practical reliability and efficiency gains. By cutting thermal resistance, resisting fatigue, and enabling higher-frequency operation, it supports ≥98% PCS efficiency, 1.8–2.2× power density, and long lifetimes in Pakistan’s high-temperature, dusty environments. This directly reduces LCOE, maintenance frequency, and commissioning risk for textile, cement, steel, and emerging industrial applications.

Connect with Specialists for Custom Solutions

Partner with Sicarb Tech to build high-reliability packaging lines:

- 10+ years of SiC manufacturing expertise

- Chinese Academy of Sciences backing and innovation pipeline

- Custom development across R-SiC, SSiC, RBSiC, and SiSiC components with advanced DBC/AMB stacks

- Technology transfer and factory establishment services—layout, tool selection, SAT/FAT, recipes, and certification support

- Turnkey solutions from materials and devices to sintering, modules, cooling, and compliance

- Proven results with 19+ enterprises improving efficiency, reliability, and time-to-market

Book a free consultation for sintering equipment specs, process recipes, and localization planning:

- Email: [email protected]

- Phone/WhatsApp: +86 133 6536 0038

Secure 2025–2026 equipment build slots and process-transfer windows to accelerate PCS and MV inverter programs across Pakistan.

Article Metadata

Last updated: 2025-09-10

Next scheduled update: 2026-01-15

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.