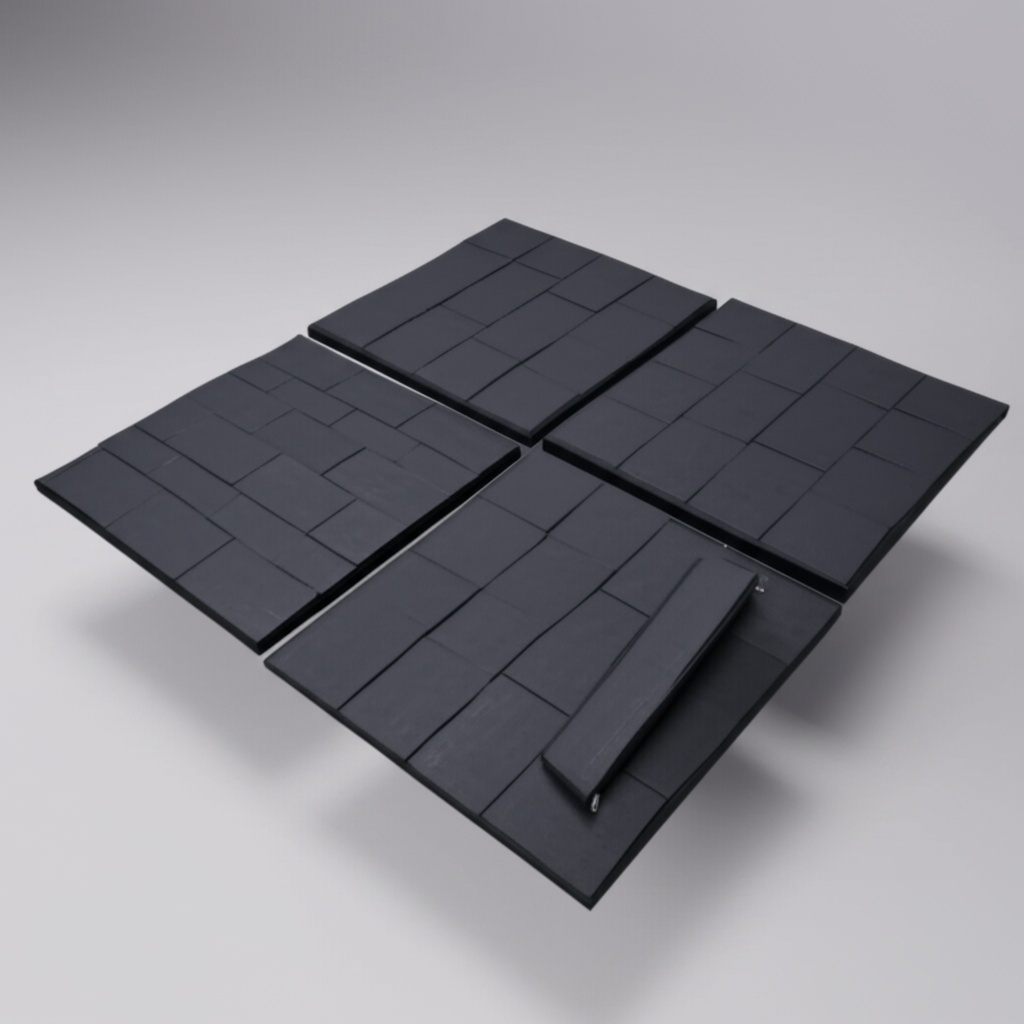

SiC Wear Liners: Maximum Equipment Protection

Share

SiC Wear Liners: Maximum Equipment Protection

In the relentless pursuit of operational efficiency and equipment longevity, industries across the globe face a common adversary: wear and tear. From abrasive slurries in mining to high-temperature environments in semiconductor fabrication, components are constantly subjected to conditions that degrade performance and necessitate costly downtime. This is where custom silicon carbide (SiC) wear liners emerge as an indispensable solution, offering unparalleled protection and extending the lifespan of critical machinery.

As a leading provider of custom silicon carbide products and equipment, we understand the intricate demands of modern industrial processes. Our expertise lies in engineering advanced ceramic solutions that not only withstand extreme conditions but also optimize system performance. This blog post delves into the transformative power of SiC wear liners, exploring their applications, advantages, and the crucial factors in their design and procurement.

The Unyielding Power of Silicon Carbide: Why SiC Wear Liners?

Silicon carbide (SiC) is a technical ceramic renowned for its exceptional properties, making it an ideal material for wear applications. When formed into wear liners, SiC provides a protective barrier that significantly outperforms traditional materials. Its unique combination of hardness, thermal stability, and chemical inertness translates directly into tangible benefits for industrial operations.

Main Applications of SiC Wear Liners Across Industries

The versatility of SiC wear liners makes them critical components across a diverse range of high-performance industrial applications. Their ability to resist abrasion, corrosion, and high temperatures makes them indispensable in environments where other materials fail.

- Semiconductor Manufacturing: Protecting critical process equipment like wafer handling systems, chemical mechanical planarization (CMP) components, and etching tools from abrasive slurries and corrosive chemicals.

- Automotive Industry: Enhancing the durability of brake components, clutch systems, and engine parts, especially in electric vehicles and high-performance cars, due to SiC’s thermal management capabilities.

- Aerospace & Defense: Used in lightweight, high-temperature components for jet engines, rocket nozzles, and missile systems, where extreme thermal and abrasive conditions are prevalent.

- Power Electronics: Improving the efficiency and reliability of power modules, inverters, and converters through superior thermal conductivity and electrical insulation properties.

- Renewable Energy: Protecting components in solar energy systems (e.g., concentrated solar power mirrors) and wind turbines (e.g., gearbox bearings) from environmental degradation and wear.

- Metallurgy & Mining: Lining chutes, hoppers, cyclones, and other equipment exposed to highly abrasive ores and slags, significantly extending operational life.

- Chemical Processing: Providing corrosion resistance in pumps, valves, and piping handling aggressive acids, alkalis, and solvents.

- LED Manufacturing: Ensuring precision and longevity in process equipment due to SiC’s high purity and resistance to etching chemistries.

- Industrial Machinery: Protecting critical wear surfaces in pumps, fans, mixers, and conveying systems in various manufacturing processes.

- Telecommunications: Utilized in high-frequency applications and components requiring excellent dielectric properties and thermal stability.

- Oil and Gas: Enhancing the durability of downhole tools, drilling equipment, and piping in highly abrasive and corrosive environments.

- Medical Devices: For components requiring biocompatibility, high wear resistance, and the ability to withstand sterilization processes.

- Rail Transportation: Improving the lifespan of brake systems and other critical wear parts.

- Nuclear Energy: Used in components requiring neutron absorption, thermal stability, and corrosion resistance in demanding reactor environments.

Advantages of Custom SiC Wear Liners

Choosing custom SiC wear liners offers a multitude of benefits that directly impact operational efficiency and cost savings for technical procurement professionals and engineers.

| Advantage | Description | Benefit for Your Operations |

|---|---|---|

| Extreme Hardness & Wear Resistance | SiC is one of the hardest materials known, second only to diamond, providing superior resistance to abrasion, erosion, and impact. | Significantly extended equipment lifespan, reduced replacement costs, and minimal downtime. |

| Excellent Thermal Stability | Maintains its mechanical properties at temperatures exceeding 1,300°C (2,372°F), ideal for high-temperature processing. | Reliable performance in extreme thermal environments, preventing thermal degradation and component failure. |

| Superior Chemical Inertness | Highly resistant to attack from acids, alkalis, and other corrosive chemicals. | Long-term durability in harsh chemical processing environments, ensuring process integrity. |

| High Thermal Conductivity | Efficiently dissipates heat, preventing hot spots and improving thermal management in critical applications. | Enhanced performance and reliability in power electronics and high-power density systems. |

| Low Thermal Expansion | Minimizes dimensional changes under thermal cycling, reducing stress and improving component longevity. | Improved dimensional stability and reduced risk of cracking in thermal shock applications. |

| Lightweight (Low Density) | Offers an excellent strength-to-weight ratio compared to many metals. | Reduced system weight, beneficial for aerospace and automotive applications, leading to improved fuel efficiency or performance. |

Recommended SiC Grades and Compositions

The performance of SiC wear liners is heavily influenced by their specific grade and composition. Understanding the distinctions between these types is crucial for optimal material selection.

- Reaction-Bonded Silicon Carbide (RBSC): Known for its high strength, excellent abrasion resistance, and good thermal shock properties. It’s often used in larger, complex shapes and offers a cost-effective solution for many industrial applications.

- Sintered Silicon Carbide (SSiC): Offers superior purity, higher strength, and improved corrosion resistance compared to RBSC. Ideal for highly demanding applications requiring extreme wear resistance and chemical inertness.

- Nitride-Bonded Silicon Carbide (NBSC): Provides a balance of strength, thermal shock resistance, and good chemical resistance, often used in applications with moderate temperatures and abrasive wear.

- Recrystallized Silicon Carbide (ReSiC): Characterized by exceptional purity and thermal shock resistance, making it suitable for very high-temperature and chemically aggressive environments, particularly in semiconductor and furnace applications.

Design Considerations for SiC Products

Effective design is paramount when working with advanced ceramics like SiC to maximize performance and manufacturability. Engineers and OEMs must consider several key factors:

- Geometry Limits: SiC is a hard and brittle material. Avoid sharp internal corners, abrupt thickness changes, and deep, narrow features that can lead to stress concentrations during manufacturing and operation.

- Wall Thickness: Aim for consistent wall thicknesses to ensure uniform heating and cooling during sintering, reducing the risk of warpage or cracking.

- Stress Points: Identify potential stress points during design, especially where components interface or undergo external forces. Design to distribute stress evenly.

- Mounting & Fastening: Consider how the SiC liner will be integrated into the larger assembly. Design appropriate mounting features that accommodate SiC’s rigidity, potentially incorporating compliant layers to absorb stress.

- Surface Area: Maximize the contact surface area in wear applications to distribute load and reduce localized wear.

- Taper & Draft Angles: Incorporate appropriate taper and draft angles for easier removal from molds during manufacturing, especially for complex shapes.

Tolerance, Surface Finish & Dimensional Accuracy

Achieving precise dimensions and surface finishes in SiC components is crucial for their performance. While SiC is extremely hard, advanced machining techniques allow for high levels of accuracy.

- Achievable Tolerances: Precision grinding and lapping can achieve tolerances in the micron range, depending on the component’s size and complexity. It’s vital to specify realistic tolerances that meet functional requirements without incurring unnecessary manufacturing costs.

- Surface Finish Options: Surface finishes can range from as-fired (rougher) to highly polished (mirror-like) depending on the application’s needs for friction, wear, and chemical inertness. Smooth finishes typically offer better wear resistance and chemical inertness.

- Dimensional Accuracy: Silicon carbide is a ceramic, and some shrinkage occurs during firing. Experienced manufacturers account for this shrinkage to ensure the final product meets specified dimensions.

Post-Processing Needs for SiC Wear Liners

While SiC offers exceptional inherent properties, certain post-processing steps can further enhance its performance and durability.

- Grinding: Precision grinding is often necessary to achieve tight tolerances and desired surface finishes, especially for mating surfaces or critical dimensions.

- Lapping & Polishing: For applications requiring extremely smooth surfaces (e.g., sealing surfaces, semiconductor equipment), lapping and polishing can reduce friction and improve wear resistance.

- Sealing/Impregnation: In some cases, SiC can be impregnated with silicon or other materials to reduce porosity and improve impermeability for specific chemical applications.

- Coating: While SiC is inherently resistant, specialized coatings can be applied for unique properties, such as enhanced lubricity or even greater chemical resistance in specific media.

Common Challenges and How to Overcome Them in SiC Applications

Despite its remarkable properties, SiC does present certain challenges that need to be addressed during design and application.

- Brittleness: Like most ceramics, SiC is brittle and susceptible to fracture under sudden impact or tensile stress.

- Mitigation: Design to minimize tensile stress and incorporate compressive stress where possible. Use generous radii in corners, avoid sharp edges, and ensure proper mounting and support to distribute loads.

- Machining Complexity: SiC’s extreme hardness makes it difficult and expensive to machine.

- Mitigation: Design parts with geometries that minimize the need for extensive post-sintering machining. Work closely with your supplier to understand their machining capabilities and design within those constraints.

- Thermal Shock: While SiC has good thermal shock resistance, rapid and extreme temperature fluctuations can still induce stress.

- Mitigation: Implement controlled heating and cooling ramps in processes. Select SiC grades with higher thermal shock resistance for demanding thermal cycling applications.

- Cost: Custom SiC components can have a higher initial cost compared to traditional materials.

- Mitigation: Focus on the total cost of ownership (TCO). The extended lifespan, reduced downtime, and improved performance of SiC often lead to significant long-term savings that far outweigh the initial investment.

How to Choose the Right SiC Supplier

Selecting a reliable and experienced SiC supplier is crucial for the success of your project. Look for partners who demonstrate technical expertise, quality assurance, and a commitment to customer service.

- Technical Capabilities: Evaluate their R&D capabilities, material science expertise, and ability to engineer custom solutions tailored to your specific application.

- Material Options: Ensure they offer a wide range of SiC grades and compositions to meet diverse performance requirements.

- Manufacturing Processes: Inquire about their manufacturing processes, quality control measures, and ability to achieve the required tolerances and surface finishes.

- Certifications: Look for certifications such as ISO 9001, which demonstrate a commitment to quality management systems.

- Experience & Track Record: Choose a supplier with a proven track record in your industry or similar demanding applications. Ask for case studies or references.

- Customization Support: A strong supplier will offer comprehensive design support, from concept to final product, assisting with material selection and optimization.

When it comes to custom silicon carbide products, we at Sicarb Tech stand out as a trusted partner. We are proud to be part of the vibrant silicon carbide manufacturing hub in Weifang City, China, which accounts for over 80% of the nation’s total SiC output. Since 2015, Sicarb Tech has been instrumental in introducing and implementing advanced SiC production technologies, assisting local enterprises in achieving large-scale production and technological advancements. We have truly witnessed the emergence and ongoing development of this thriving industry.

As an entrepreneurial park that collaborates closely with the National Technology Transfer Center of the Chinese Academy of Sciences , Sicarb Tech leverages the robust scientific and technological capabilities and talent pool of the Chinese Academy of Sciences. This unique position allows us to serve as a bridge, facilitating the integration and collaboration of crucial elements in the transfer and commercialization of scientific and technological achievements. We offer more reliable quality and supply assurance within China, possessing a domestic top-tier professional team specializing in customized production of silicon carbide products. With our support, over 368 local enterprises have benefited from our technologies, encompassing material, process, design, measurement, and evaluation expertise. This integrated approach, from materials to products, enables us to meet diverse customization needs and offer you higher-quality, cost-competitive customized silicon carbide components in China.

Furthermore, if you are looking to establish a professional silicon carbide products manufacturing plant in your own country, Sicarb Tech can provide comprehensive technology transfer for professional silicon carbide production. Our full-range services (turnkey project) include factory design, procurement of specialized equipment, installation and commissioning, and trial production. This ensures a more effective investment, reliable technology transformation, and a guaranteed input-output ratio, allowing you to own a professional silicon carbide products manufacturing plant with confidence. Learn more about our capabilities and commitment to quality on our About Us page or explore our technology transfer services.

Cost Drivers and Lead Time Considerations for SiC Components

Understanding the factors that influence the cost and lead time of custom SiC components is essential for effective project planning and procurement managers.

| Cost Driver | Description | Impact |

|---|---|---|

| Material Grade & Purity | Higher purity SiC (e.g., SSiC, ReSiC) and specialized compositions are more expensive. | Increases raw material cost, but may offer superior performance. |

| Component Complexity | Intricate geometries, tight tolerances, thin walls, and complex internal features. | Requires more advanced manufacturing techniques and machining, driving up production costs and lead times. |

| Volume | Smaller batch sizes often have higher unit costs due to setup and tooling expenses. | Larger volumes typically benefit from economies of scale, reducing per-unit cost. |

| Post-Processing Needs | Extensive grinding, lapping, polishing, or specialized coatings. | Adds to labor and machine time, increasing overall cost. |

| Design & Engineering Support | Extensive R&D, custom tooling, and engineering consultation. | May add to initial project cost, but often saves significant expense in the long run by optimizing design and preventing failures. |

Lead times are influenced by similar factors, with complex designs, specialized materials, and smaller production runs generally requiring longer lead times. It’s crucial to communicate your project timelines early with your supplier to ensure realistic expectations and timely delivery.

Frequently Asked Questions (FAQ) about SiC Wear Liners

Here are some common questions we receive regarding silicon carbide wear liners:

- Q1: How long do SiC wear liners typically last compared to steel or alumina?

- A1: SiC wear liners typically offer 5 to 10 times, and often much longer, the lifespan of traditional materials like hardened steel or alumina in abrasive and corrosive environments. The exact lifespan depends heavily on the specific application conditions, but the improvement is substantial, leading to significant reductions in maintenance and replacement costs.

- Q2: Can SiC wear liners be repaired or refurbished?

- A2: While SiC is extremely durable, individual SiC wear liners are typically replaced rather than repaired if damaged. However, in modular designs, individual worn liners can be replaced without replacing the entire system. Proper initial design and material selection minimize the need for frequent replacement.

- Q3: What are the temperature limitations for SiC wear liners?

- A3: SiC wear liners can withstand extremely high temperatures, maintaining their mechanical properties up to 1,300°C (2,372°F) and even higher in certain grades. This makes them ideal for high-temperature furnaces, combustion systems, and other thermal processing applications where metals would deform or melt.

Conclusion: Investing in Durability with SiC Wear Liners

In today’s demanding industrial landscape, the choice of materials can make or break an operation. Custom silicon carbide wear liners represent a pivotal investment in the longevity, efficiency, and reliability of your equipment. Their unparalleled hardness, thermal stability, and chemical inertness provide maximum equipment protection, significantly reducing downtime and lowering overall operational costs.

By partnering with a knowledgeable and experienced SiC manufacturer like Sicarb Tech, you gain access to cutting-edge material science, precision engineering, and a commitment to delivering tailor-made solutions for your most challenging applications. Embrace the power of advanced ceramics and unlock new levels of performance and durability for your industrial processes. Contact us today to discuss your specific requirements and discover how custom SiC wear liners can transform your operations.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.