Unlocking Superior Performance: A Comprehensive Guide to Custom Silicon Carbide Rings

Share

In the ever-evolving landscape of industrial technology, the demand for materials that can withstand extreme conditions is paramount. Components must not only survive but excel in environments characterized by high temperatures, corrosive chemicals, and severe abrasion. Among the advanced technical ceramics, silicon carbide (SiC) has emerged as a frontrunner, and custom silicon carbide rings stand out as critical components enabling breakthroughs in a multitude of high-performance industrial applications. These are not mere off-the-shelf parts; they are precision-engineered solutions tailored to meet the unique challenges of each application, offering unparalleled durability, thermal stability, and chemical resistance where conventional materials falter. This guide will delve into the world of custom SiC rings, exploring their diverse applications, the distinct advantages of bespoke designs, material selection intricacies, critical engineering considerations, and how to partner with the right supplier, such as Sicarb Tech, to unlock their full potential. Whether you are an engineer designing next-generation equipment, a procurement manager sourcing resilient components, or a technical buyer seeking a competitive edge, understanding the strategic value of custom SiC rings is essential.

Versatile Applications: How Industries Leverage Custom Silicon Carbide Rings

The unique cylindrical geometry of rings, combined with the exceptional properties of silicon carbide, makes custom SiC rings indispensable across a wide spectrum of industries. Their ability to perform reliably under duress translates directly into enhanced operational efficiency, reduced downtime, and improved product quality.

In semiconductor manufacturing, the demand for ultra-high purity and exceptional thermal stability is non-negotiable. Custom SiC rings find use in critical components like edge rings or support rings within plasma etch chambers and chemical vapor deposition (CVD) systems. Their resistance to corrosive plasma environments and minimal particle generation are vital for maintaining wafer integrity and yield.

The high-temperature processing and furnace industries rely heavily on materials that can endure extreme thermal cycling and maintain structural integrity at elevated temperatures. SiC rings are employed as kiln furniture, support structures for heating elements, and components within industrial burners and nozzles. Their excellent thermal shock resistant ceramics properties and high-temperature strength ensure longevity and consistent performance.

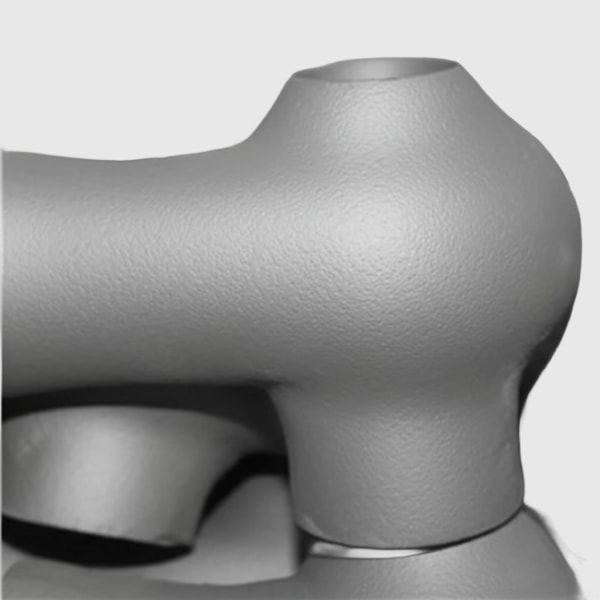

Aerospace and defense applications push materials to their limits. Custom SiC rings are utilized in lightweight, high-stiffness bearing components and sophisticated SiC mechanical seals for auxiliary power units (APUs), hydraulic systems, and fuel pumps operating in demanding environments. Their low density compared to traditional high-performance metals also contributes to weight savings, a critical factor in aerospace design.

The energy sector, encompassing power generation, oil and gas exploration, and petrochemical processing, frequently encounters abrasive and corrosive media at high pressures and temperatures. Wear-resistant SiC rings are the gold standard for mechanical seal faces in pumps, compressors, and mixers, preventing leakage and ensuring the reliability of critical rotating equipment. Their ability to withstand harsh downhole conditions in oil and gas extraction tools further highlights their robustness.

In broader industrial manufacturing, including chemical processing, pharmaceuticals, and pulp and paper, the need for components that resist aggressive chemicals and abrasive slurries is constant. Custom SiC rings serve as crucial elements in pumps (seal faces, bushings, sleeves), valves (seats, stems), and various other fluid handling systems. The chemical resistant SiC components, particularly those made from Sintered Silicon Carbide (SSiC), offer unmatched performance in these challenging applications.

Below is a table summarizing some key applications:

| Industry Sector | Typical SiC Ring Applications | Key Benefits Provided by Custom SiC Rings |

|---|---|---|

| Semiconductor | Edge rings, Chamber components, Wafer chucks | High purity, Plasma resistance, Thermal stability, Dimensional precision |

| High-Temperature | Kiln furniture, Burner nozzles, Support rings | High-temperature strength, Thermal shock resistance, Creep resistance |

| Aerospace & Defense | Mechanical seals, Bearing components | Wear resistance, Low friction, Lightweight, High stiffness |

| Energy (Oil & Gas, Power) | Mechanical seals, Pump components, Valves | Abrasion resistance, Corrosion resistance, High pressure tolerance |

| Chemical Processing | Mechanical seals, Pump sleeves, Bearings | Extreme chemical inertness, Wear resistance, Contamination prevention |

| Industrial Manufacturing | Wear parts, Nozzles, Bearings | Extended service life, Reduced maintenance, Improved reliability |

The versatility of custom silicon carbide rings underscores their importance as enabling components in processes that define modern industrial capability.

Why Customization Matters: Unlocking Peak Performance with Tailored SiC Rings

While standard SiC components offer significant advantages, the ability to procure custom silicon carbide rings tailored to specific operational needs unlocks a new echelon of performance and reliability. Generic solutions may suffice for some applications, but when facing unique challenges or striving for optimal efficiency, customization becomes a critical differentiator. This bespoke approach allows engineers and designers to move beyond the constraints of off-the-shelf parts and achieve a truly optimized system.

One of the primary drivers for customization is enhanced thermal management. The geometry of a ring can be meticulously designed for optimal heat dissipation in applications like high-performance seals or adapted for maximum heat retention where required. Furthermore, the selection of specific SiC grades with tailored thermal conductivity, coupled with custom designs, ensures that the component performs predictably under fluctuating thermal loads, enhancing the lifespan of the entire assembly. This focus on thermal shock resistant ceramics through design is crucial.

Superior wear resistance is another key benefit. In dynamic applications such as SiC mechanical seals or bearings, even minute imperfections or suboptimal designs can lead to premature failure. Customization allows for the creation of ring profiles that minimize friction, optimize lubrication film formation (if applicable), and withstand specific abrasive or erosive media. Material compositions can also be fine-tuned; for instance, incorporating graphite into the SiC matrix can improve tribological properties for dry-running seal applications. This results in significantly longer service life and reduced maintenance intervals for wear-resistant SiC rings.

For industries dealing with highly corrosive substances, uncompromised chemical inertness is paramount. Custom SiC rings, particularly those fabricated from high-purity Sintered Silicon Carbide (SSiC), can be designed to eliminate crevices or features that might trap reactive chemicals, thus preventing localized corrosion. The choice of the SiC grade itself is a critical customization parameter, ensuring compatibility with the most aggressive acids, alkalis, or solvents. This makes chemical resistant SiC components a reliable choice.

Beyond thermal and chemical considerations, optimized mechanical performance is a significant advantage of custom designs. Dimensions, tolerances, and surface finishes can be specified with exacting precision to ensure perfect mating with other components, critical for achieving effective sealing or precise alignment. Stress concentrations can be minimized through thoughtful design, such as incorporating specific radii or chamfers, thereby enhancing the ring’s ability to withstand mechanical loads and vibrations inherent in its operating environment. This level of custom SiC manufacturing ensures the component is perfectly suited for its intended purpose.

Ultimately, the decision to opt for custom SiC rings contributes to improved system efficiency and lifespan. By addressing the specific nuances of an application, these tailored components help maximize Overall Equipment Effectiveness (OEE), reduce unscheduled downtime, minimize the risk of catastrophic failures, and often lead to lower total cost of ownership despite a potentially higher initial investment compared to standard parts.

Key advantages of opting for custom SiC rings include:

- Application-Specific Design: Geometries and features engineered precisely for the intended function and environment.

- Optimized Material Grade Selection: Choice of SiC type (RBSiC, SSiC, etc.) and composition to match thermal, chemical, and mechanical demands.

- Precision Tolerances and Finishes: Ensuring exact fit and superior performance, especially in sealing and high-precision alignment applications.

- Enhanced Component Lifespan: Reduced wear, corrosion, and risk of thermal shock failure leading to longer operational life.

- Improved Overall System Reliability: Contributing to the stability and efficiency of the larger equipment or process.

- Potential for Miniaturization or Integration: Custom designs can accommodate complex assemblies or space-constrained applications.

By partnering with a knowledgeable supplier capable of intricate OEM SiC parts customization, industries can leverage these benefits to achieve superior performance and a distinct competitive advantage.

Choosing Your Material: An Engineer’s Guide to SiC Grades for Rings

The exceptional performance of silicon carbide rings stems from the inherent properties of SiC, but not all SiC is created equal. Various manufacturing processes yield different grades of silicon carbide, each with a unique combination of characteristics. Selecting the appropriate SiC grade is a critical step in designing or specifying custom silicon carbide rings to ensure optimal performance, longevity, and cost-effectiveness for a given application. Engineers and procurement professionals must understand these distinctions to make informed decisions.

Reaction-Bonded Silicon Carbide (RBSiC), also known as Silicon Infiltrated Silicon Carbide (SiSiC): RBSiC is produced by infiltrating a porous preform, typically made of SiC grains and carbon, with molten silicon. The silicon reacts with the carbon to form additional SiC, which bonds the original SiC grains.

- Properties: RBSiC offers a good balance of mechanical strength, excellent thermal shock resistance, and high thermal conductivity. It exhibits near-net-shape manufacturing capabilities, often reducing the need for extensive post-sintering machining. A key characteristic is the presence of some residual free silicon (typically 8-15%) within the microstructure. This free silicon can limit its use in extremely high temperatures (above 1350∘C) or in contact with certain aggressive chemicals like strong alkalis or hydrofluoric acid.

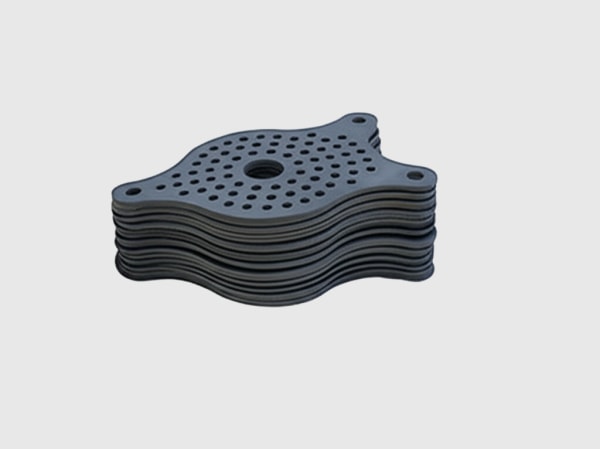

- Typical Applications for RBSiC/SiSiC Rings: Due to its cost-effectiveness and good all-around properties, RBSiC rings and SiSiC rings are widely used in applications such as mechanical seal faces for general industrial pumps, bearings, nozzles, and kiln furniture where extreme chemical purity is not the primary concern.

Sintered Silicon Carbide (SSiC): SSiC is produced by sintering fine SiC powders at very high temperatures (typically above 2000∘C), often with the aid of non-oxide sintering additives like boron and carbon (solid-state sintered SSiC) or oxide additives (liquid-phase sintered SSiC).

- Properties: SSiC is characterized by its very high purity (typically >98-99% SiC), leading to exceptional corrosion resistance against a wide range of chemicals, including strong acids and bases. It boasts superior hardness, high strength (even at elevated temperatures), and excellent wear resistance. Its thermal conductivity is generally lower than RBSiC but still good.

- Typical Applications for SSiC Rings: The outstanding chemical inertness and wear resistance make SSiC rings the preferred choice for demanding applications such as mechanical seals in highly corrosive chemical pumps, bearings in aggressive media, semiconductor processing equipment components, and any application requiring maximum material purity and durability.

Nitride-Bonded Silicon Carbide (NBSiC): NBSiC is manufactured by bonding SiC grains with silicon nitride (Si3N4). This is typically achieved by nitriding a mixture of SiC powder and silicon powder.

- Properties: NBSiC provides good thermal shock resistance, good wear resistance, and notable resistance to wetting by molten non-ferrous metals. Its strength is generally lower than SSiC or RBSiC, but it offers good performance in specific environments.

- Typical Applications for NBSiC Rings: Nitride-bonded SiC rings are often found in applications involving molten aluminum and other non-ferrous metals, such as thermocouple protection tubes, and certain types of kiln furniture or wear components where its specific combination of properties is advantageous.

Other Specialized Options: While RBSiC and SSiC are the most common grades for ring applications, other specialized forms or treatments exist:

- Graphite-Loaded SiC: Small amounts of graphite can be incorporated into SiC (often SSiC) to improve its tribological properties, particularly for dry-running mechanical seals, by acting as a solid lubricant.

- CVD SiC (Chemical Vapor Deposition SiC): This process produces an ultra-pure, dense SiC coating or freestanding component. While expensive, it offers the highest purity and corrosion resistance, sometimes used for critical semiconductor parts. For rings, CVD SiC might be used as a coating on another SiC grade to enhance surface properties.

The selection process involves a careful evaluation of the operating conditions. A comparative overview is presented below:

| SiC Grade | Key Properties | Advantages | Disadvantages | Typical Ring Applications |

|---|---|---|---|---|

| RBSiC / SiSiC | Good strength, Excellent thermal shock resistance, High thermal conductivity, Good wear resistance | Cost-effective, Near-net-shape capability, Good machinability (pre-infiltration) | Contains free silicon (limits temp. to ~1350∘C & chemical resistance) | General purpose mechanical seals, Bearings, Kiln furniture, Nozzles |

| SSiC (Solid-State/Liquid Phase) | Highest purity, Excellent corrosion resistance, High hardness & strength, Good high-temp. performance | Superior in aggressive chemical environments, Longest wear life | Higher cost, More challenging to machine | Chemical pump seals, Semiconductor parts, High-performance bearings |

| NBSiC | Good thermal shock resistance, Good wear resistance, Molten metal resistance | Good for specific non-ferrous metal contact, Moderate cost | Lower strength than RBSiC/SSiC, Porosity can be a factor | Molten metal handling, Specialised kiln furniture, Some wear parts |

Understanding these material nuances is crucial for any technical ceramic procurement process. Consulting with experienced SiC component suppliers like Sicarb Tech can provide invaluable guidance in selecting the optimal SiC grade to ensure your custom rings deliver the desired performance and longevity.

Precision Engineering: Critical Design, Tolerance, and Finishing Considerations for SiC Rings

The exceptional intrinsic properties of silicon carbide are only fully realized when coupled with precision engineering throughout the design and manufacturing process of custom SiC rings. Attention to detail in design for manufacturability, achievable tolerances, surface finish specifications, and appropriate post-processing are all critical to producing a component that performs reliably and meets the exacting demands of its application.

Design for Manufacturability (DfM): Collaborating with SiC specialists, such as the expert team at Sicarb Tech, early in the design phase is paramount. This ensures that the proposed ring design is not only functional but also manufacturable in a cost-effective and reliable manner.

- Geometric Complexity: While SiC can be formed into intricate shapes, overly complex geometries for rings can increase manufacturing challenges and costs. Simple bands, stepped rings, and rings with specific grooves or chamfers are common. The manufacturing process (e.g., pressing, slip casting, green machining before sintering) will dictate some geometric limitations.

- Wall Thickness: Adequate wall thickness is crucial to prevent stress concentrations, ensure structural integrity during manufacturing (especially handling in the “green” state), and withstand operational loads. Thin, delicate sections are prone to damage and can be difficult to produce consistently.

- Avoiding Stress Raisers: Sharp internal corners should be avoided wherever possible; incorporating radii can significantly improve the ring’s strength and resistance to chipping or cracking. External edges may benefit from chamfers or radii to prevent chipping during handling or assembly.

Tolerances & Dimensional Accuracy: Silicon carbide is an extremely hard material, which makes achieving tight tolerances a specialized and often costly process.

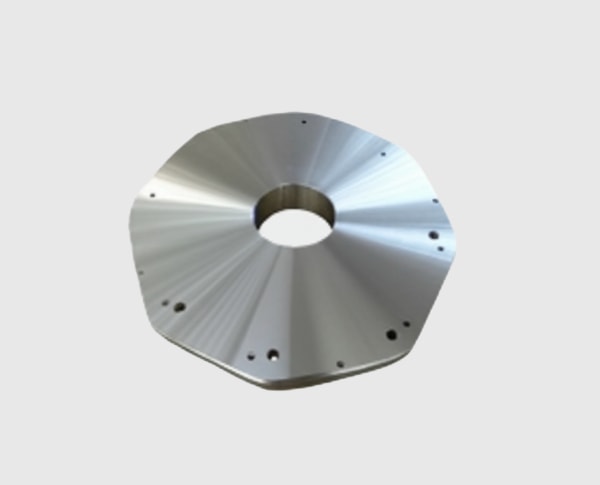

- Achievable Tolerances: “As-sintered” tolerances for SiC rings can vary depending on the SiC grade, manufacturing route, and part size. While processes like Reaction-Bonded SiC (RBSiC) offer good near-net-shape capabilities, achieving very tight tolerances typically requires post-sintering diamond grinding. Precision ground SiC rings can achieve dimensional tolerances in the range of $\pm 0.005$mm to $\pm 0.025$mm, and in some cases, even tighter for critical features like flatness or parallelism in seal faces.

- Influencing Factors: The final dimensional accuracy is influenced by the chosen material grade (SSiC typically shrinks more and less predictably than RBSiC during sintering), the complexity of the ring’s geometry, and the overall size of the component.

- Clear Specifications: It is vital for engineers to clearly define and communicate all critical dimensions and their required tolerances on engineering drawings. Over-specifying tolerances unnecessarily can significantly increase costs.

Surface Finish Options: The required surface finish of a SiC ring is highly dependent on its application.

- As-Fired Finish: The surface of a SiC ring after sintering will have a certain inherent roughness. For some applications, such as kiln furniture or general wear parts, an as-sintered finish may be acceptable.

- Grinding, Lapping, and Polishing: For applications like SiC mechanical seals, bearing races, or components requiring precise mating, smooth surfaces are essential. Diamond grinding can achieve surface roughness (Ra) values typically around $0.2 \mu$m to $0.8 \mu$m. Lapping can further improve this to $R_a < 0.2 \mu$m, and polishing can achieve mirror-like finishes with $R_a < 0.05 \mu$m, critical for dynamic sealing faces to ensure minimal leakage and low friction.

- Impact on Performance: Surface finish directly impacts friction, wear rates, sealing efficiency, and the potential for particle generation. Smoother, well-finished surfaces generally lead to superior performance in dynamic applications.

Post-Processing Needs: Beyond initial forming and sintering, several post-processing steps may be necessary to meet the final specifications for custom SiC rings:

- Precision Grinding and Lapping: As mentioned, these are the most common and critical post-processing steps for achieving tight dimensional tolerances and fine surface finishes on hard SiC materials.

- Edge Treatment: Edge chamfering or radiusing can prevent chipping and improve handling safety and component durability.

- Coatings (Specialized Cases): While SiC itself offers excellent properties, in some niche applications, coatings like Diamond-Like Carbon (DLC) might be applied to SiC rings to further reduce friction or enhance wear resistance in specific counter-material pairings.

- Cleaning and Packaging: For high-purity applications, such as in the semiconductor or pharmaceutical industries, rigorous cleaning procedures and specialized packaging are essential to prevent contamination.

Engineering Tips for Custom SiC Rings:

- Engage with your SiC supplier early to discuss design feasibility.

- Clearly define critical-to-function dimensions and tolerances. Avoid over-tolerancing non-critical features.

- Specify surface finish requirements based on the application (e.g., flatness and roughness for seal faces).

- Consider the operating environment (temperature, chemicals, loads) when selecting material and designing the ring.

- Inquire about the supplier’s capabilities in precision SiC machining and quality control.

By carefully considering these engineering aspects, companies can ensure that their custom SiC manufacturing projects result in components that deliver exceptional performance and reliability.

Overcoming Hurdles & Selecting Your SiC Ring Supplier: A Buyer’s Guide

While custom silicon carbide rings offer remarkable advantages, their specification, procurement, and implementation are not without potential challenges. Understanding these hurdles and knowing how to select a capable and reliable SiC component supplier are crucial for technical buyers, procurement professionals, and engineers aiming to integrate these advanced materials successfully.

Common Challenges in SiC Ring Production & Use:

- Brittleness: Silicon carbide, like most technical ceramics, is inherently brittle. This means it has low fracture toughness compared to metals. Improper design (e.g., sharp corners, stress concentrations), mishandling during assembly, or severe impact can lead to chipping or catastrophic fracture. Mitigation strategies include careful design (incorporating radii, chamfers), controlled assembly procedures, and selecting grades with optimized toughness where possible.

- Machining Complexity & Cost: The extreme hardness of SiC (second only to diamond and boron carbide) makes it very difficult and time-consuming to machine. Specialized diamond grinding tools, rigid machinery, and experienced technicians are required. This precision SiC machining adds significantly to the cost of finished SiC components compared to metals or softer ceramics. Minimizing machining by designing for near-net-shape manufacturing is often a key cost-control strategy.

- Thermal Shock Susceptibility (Relative): While SiC generally exhibits excellent thermal shock resistance due to its high thermal conductivity and relatively low thermal expansion, extremely rapid and severe temperature changes can still induce cracks, especially in complex shapes or larger components. Material selection (RBSiC often has better thermal shock resistance than SSiC due to higher thermal conductivity and a more heterogeneous microstructure) and careful operational design can mitigate this.

- Cost Justification: Custom SiC rings are typically more expensive upfront than components made from conventional materials like stainless steel, hardened alloys, or even some other ceramics like alumina. The higher initial cost must be justified by the significantly longer service life, reduced downtime, improved performance in aggressive environments, and lower total cost of ownership that SiC offers.

- Joining to Other Materials: Integrating SiC rings into assemblies with metallic or other ceramic components can be challenging due to differences in coefficients of thermal expansion (CTE). Techniques like brazing, shrink-fitting, or adhesive bonding require careful design and process control to avoid stress buildup and ensure a durable bond.

How to Choose the Right SiC Ring Supplier:

Selecting a competent supplier is perhaps the most critical step in ensuring the success of your custom SiC ring project. Consider the following criteria:

- Technical Expertise & Experience: Look for a supplier with a proven track record in manufacturing custom SiC components, particularly rings, for your specific industry or a similar demanding application. Their engineers should be able to provide design assistance and material selection advice.

- Material Options & Quality Control: The supplier should offer a range of relevant SiC grades (RBSiC, SSiC, etc.) and be transparent about their material sourcing and properties. Stringent quality control processes, including material certification, dimensional inspection (using CMMs, optical comparators, etc.), and surface finish verification, are essential.

- Manufacturing Capabilities: Assess their in-house capabilities for powder preparation, forming (pressing, casting, extrusion), sintering, and, crucially, precision diamond grinding and lapping. A vertically integrated supplier often offers better control over quality and lead times.

- Customization Support & DfM: The ideal partner will work collaboratively with you on design for manufacturability (DfM), helping to optimize your ring design for performance and cost-effectiveness. Responsiveness to technical queries is key.

- Certifications & Compliance: Relevant quality certifications (e.g., ISO 9001) demonstrate a commitment to quality management. For specific industries (e.g., aerospace, medical), other compliance standards may be necessary.

- Communication, Lead Time & Cost: Clear and timely communication is vital. Obtain realistic lead time estimates and transparent pricing. While cost is a factor, it should be balanced against quality, reliability, and technical support.

A supplier evaluation checklist can be helpful:

| Evaluation Criterion | Key Questions to Ask / Aspects to Verify |

|---|---|

| Technical Expertise | Experience with SiC rings? Industry-specific knowledge? Design support? |

| Material Quality | Range of SiC grades? Material data sheets? Traceability? Purity? |

| Manufacturing Capabilities | In-house forming, sintering, grinding, lapping? Tolerances achievable? |

| Quality Assurance | ISO certification? Inspection equipment? Testing procedures? Defect rates? |

| Customization & Engineering | DfM support? Prototyping services? Engineering consultation? |

| Supply Chain & Logistics | Lead times (prototype & production)? On-time delivery record? Packaging? |

| Cost & Commercial Terms | Transparent pricing? Payment terms? Volume discounts? |

| References & Reputation | Customer testimonials? Case studies? Market reputation? |

Navigating the complexities of technical ceramic procurement for OEM SiC parts requires due diligence. By understanding potential challenges and carefully evaluating suppliers, businesses can forge partnerships that deliver high-performance, reliable custom silicon carbide rings.

The Sicarb Tech Advantage in Custom SiC Ring Manufacturing

When sourcing custom silicon carbide rings, partnering with a supplier that combines deep material expertise, advanced manufacturing capabilities, and a commitment to customer success is crucial. Sicarb Tech embodies these qualities, offering a distinct advantage to clients worldwide, rooted in its unique position within China’s advanced ceramics landscape.

Hub of China’s SiC Expertise: Sicarb Tech is strategically located in Weifang City, recognized as the hub of China’s silicon carbide customizable parts manufacturing. This region is home to over 40 SiC production enterprises of varying sizes, collectively accounting for more than 80% of the nation’s total silicon carbide output. Since 2015, SicSino has been instrumental in this ecosystem, introducing and implementing advanced silicon carbide production technology. We have actively assisted local enterprises in achieving large-scale production and significant technological advancements in their product processes, witnessing firsthand the emergence and continuous development of this vital industry. This deep immersion provides SicSino with unparalleled insights and access to a robust supply chain.

Backed by the Prestigious Chinese Academy of Sciences: Our credibility and technological prowess are significantly enhanced by our affiliation. Sicarb Tech is part of the Chinese Academy of Sciences(Weifang) Innovation Park, an entrepreneurial park that collaborates closely with the National Technology Transfer Center of the Chinese Academy of Sciences. This park serves as a national-level innovation and entrepreneurship service platform, integrating innovation, entrepreneurship, technology transfer, venture capital, incubation, acceleration, and scientific and technological services. This backing allows SicSino to capitalize on the robust scientific, technological capabilities, and extensive talent pool of the Chinese Academy of Sciences. We serve as a vital bridge, facilitating the integration and collaboration of crucial elements in the transfer and commercialization of scientific and technological achievements. This foundation has enabled us to establish a comprehensive service ecosystem that spans the entire spectrum of the technology transfer and transformation process, ensuring our clients benefit from cutting-edge material science and process innovations.

Unparalleled Customization Capabilities for SiC Rings: At SicSino, we pride ourselves on our domestic top-tier professional team specializing in the customized production of silicon carbide products, including highly precise silicon carbide rings. Our technological support has benefited over ten local enterprises, enhancing their capabilities. Our expertise is comprehensive, encompassing:

- Material Technology: Deep understanding of various SiC grades (RBSiC, SSiC, etc.) and their nuanced properties.

- Process Technology: Mastery over forming, sintering, and advanced machining processes tailored for SiC.

- Design Technology: Collaborative design and DfM services to optimize ring performance and manufacturability.

- Measurement & Evaluation Technology: State-of-the-art inspection and testing to ensure every ring meets stringent specifications. This integrated process, from raw materials to finished custom SiC manufacturing products, allows us to meet the most diverse and demanding customization needs for silicon carbide rings.

Benefits for Our Global Clientele: Choosing Sicarb Tech for your custom SiC rings translates into tangible benefits:

- Higher-Quality, Cost-Competitive Components: Leveraging our technological efficiencies and the economies of scale within the Weifang SiC cluster, we offer premium quality custom SiC rings at highly competitive prices.

- Reliable Quality and Supply Assurance: Our deep roots in China’s SiC industry and our Chinese Academy of Sciences backing ensure consistent quality and a dependable supply chain, critical for OEM production schedules.

- Deep Understanding of Customization: We don’t just manufacture parts; we provide solutions. Our team works closely with clients to understand their specific application challenges and deliver rings that are truly fit-for-purpose.

Beyond Components – Technology Transfer Services: SicSino is also committed to fostering global SiC production capabilities. For clients looking to establish their own specialized silicon carbide products manufacturing plant, we offer comprehensive technology transfer services. This turnkey solution includes factory design, procurement of specialized equipment, installation and commissioning, and trial production support. This unique offering enables businesses to develop their own professional SiC production facilities with a more effective investment, reliable technology transformation, and a guaranteed input-output ratio.

When your applications demand the utmost in performance from silicon carbide rings, Sicarb Tech stands ready as your trusted partner, offering a potent combination of Chinese manufacturing prowess, Chinese Academy of Sciences-backed innovation, and a profound commitment to delivering customized excellence.

Frequently Asked Questions (FAQ) about Custom Silicon Carbide Rings

Navigating the specifics of advanced materials like silicon carbide often brings questions to the forefront for engineers, designers, and procurement specialists. Here are answers to some common queries regarding custom silicon carbide rings:

Q1: What are the primary advantages of SiC rings over tungsten carbide or ceramic-coated metal rings in abrasive environments? A: Silicon carbide rings, particularly Sintered SiC (SSiC), offer several key advantages over tungsten carbide (WC) and ceramic-coated metals in highly abrasive environments:

- Higher Hardness (in some grades): While WC is very hard, certain grades of SiC (especially SSiC) can exhibit comparable or even superior hardness, leading to excellent abrasion resistance.

- Lower Density: SiC is significantly lighter than WC (typically around 3.1−3.2g/cm3 for SiC vs. 14−15g/cm3 for WC). In dynamic applications like high-speed mechanical seals, lower mass reduces inertial forces, allows for better tracking of mating faces, and can lead to reduced power consumption and wear.

- Superior Corrosion Resistance: SiC, especially SSiC, is virtually chemically inert to a much wider range of corrosive media, including strong acids and alkalis, where WC (which uses a metallic binder like cobalt or nickel) can corrode. Ceramic coatings on metal rings can provide protection, but if the coating is breached through wear or impact, the underlying metal is susceptible to attack. SiC offers bulk corrosion resistance.

- Better High-Temperature Stability: SiC maintains its strength and corrosion/oxidation resistance at much higher temperatures than most WC grades or metal-based components.

- Thermal Properties: SiC generally has good thermal conductivity and excellent thermal shock resistance, allowing it to manage heat effectively in high-friction applications. These factors often translate to significantly longer service life, reduced risk of product contamination (as SiC does not leach metallic ions), and more reliable performance for wear-resistant SiC rings in challenging abrasive and corrosive duties.

Q2: How tight can tolerances be for custom SiC rings, and what surface finish is achievable for applications like mechanical seals? A: The achievable tolerances and surface finishes for custom SiC rings depend on the manufacturing process (as-sintered vs. machined) and the specific SiC grade.

- Tolerances: For as-sintered parts, tolerances are generally wider. However, for applications requiring precision, post-sintering diamond grinding is employed. With precision grinding and lapping, dimensional tolerances can be very tight. For critical dimensions such as inner/outer diameters, thickness, parallelism, and flatness (especially for SiC mechanical seals), tolerances can typically be held within $\pm 0.005$mm to $\pm 0.025$mm (i.e., 5μm to 25μm). In some ultra-precision applications, even tighter tolerances are possible but come at an increased cost. Sicarb Tech possesses the advanced machining capabilities to meet such demanding specifications.

- Surface Finish: For mechanical seal faces, an extremely smooth and flat surface is critical for effective sealing and minimizing friction. Standard ground finishes might be around Ra=0.2 to 0.4μm. Lapped finishes can achieve Ra<0.2μm, and polished SiC seal faces can reach Ra<0.05μm or even down to Ra≈0.02μm. Flatness values can be controlled to within a few helium light bands (HLB). These ultra-smooth surfaces ensure a robust fluid film and minimize leakage.

Q3: What information do I need to provide to get an accurate quote for custom SiC rings from SicSino? A: To receive the most accurate and timely quotation for your custom silicon carbide rings from Sicarb Tech, please provide as much of the following information as possible:

- Detailed Engineering Drawings: These should clearly specify all dimensions, required tolerances for each dimension, geometric tolerances (e.g., flatness, parallelism, perpendicularity, concentricity), and any critical features.

- Material Grade Specification: Indicate the desired type of silicon carbide (e.g., RBSiC/SiSiC, SSiC – specifying purity if known, or other types). If unsure, describe the application environment.

- Required Quantity: Specify the number of rings needed for prototypes, initial production runs, and estimated annual usage, as quantity significantly impacts pricing.

- Application Details: A description of how and where the ring will be used is very helpful. This includes:

- Operating temperature (continuous and peak).

- Chemical environment (specific chemicals, concentrations).

- Mechanical loads or pressures involved.

- Nature of any abrasive media or wear conditions.

- For seals: mating face material, PV value (Pressure x Velocity), fluid being sealed.

- Surface Finish Requirements: Specify the required surface roughness (Ra) for different surfaces, and any flatness or parallelism requirements, especially for sealing faces.

- Testing and Certification: Any specific testing (e.g., leak testing, material analysis) or certifications (e.g., material compliance certs) required.

- Target Price & Delivery Schedule (if applicable): While not always necessary upfront, this can help guide the quoting process. The more comprehensive the information you provide, the better we can understand your needs and offer a precise, competitive quotation for your OEM SiC parts.

Conclusion: The Strategic Value of Custom SiC Rings in Advanced Industries

In the demanding theatre of modern industrial operations, the strategic selection of high-performance materials is no longer a mere consideration but a fundamental pillar of success. Custom silicon carbide rings represent a pinnacle of material engineering, offering an unparalleled combination of hardness, wear resistance, thermal stability, and chemical inertness that empowers industries to push beyond conventional limitations. From the ultra-clean environments of semiconductor fabrication to the punishing conditions of chemical processing and high-temperature furnaces, these bespoke components are not just parts; they are enabling solutions that drive efficiency, enhance reliability, and extend the operational lifespan of critical equipment.

The journey through understanding SiC grades, appreciating the nuances of precision design and manufacturing, and selecting a knowledgeable supplier underscores that the true value of custom SiC rings lies in their tailored nature. The ability to specify exact dimensions, tolerances, surface finishes, and material compositions transforms a standard component into a strategic asset, precisely optimized for its intended application. This level of customization, as offered by expert manufacturers like Sicarb Tech with their deep technological expertise and advantageous position within China’s SiC manufacturing hub, ensures that businesses are not just acquiring a product, but a performance guarantee.

Investing in high-quality, custom-engineered silicon carbide rings is an investment in long-term operational excellence. It’s a decision that mitigates risk, reduces costly downtime, and contributes to safer, more productive industrial processes. As industries continue to innovate and face ever more challenging operational environments, the demand for superior material solutions like custom silicon carbide products will only escalate.

We encourage engineers, procurement managers, and technical buyers to explore the transformative potential of custom SiC rings for their specific needs. To discuss your unique requirements and discover how Sicarb Tech can deliver cost-effective, high-performance silicon carbide solutions tailored to your applications, we invite you to reach out to our team of experts. Let us help you unlock the strategic value that these remarkable technical ceramics can bring to your most demanding industrial challenges.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.