Integrated SiC UPS Rectifier–Inverter Modules with >98% Efficiency for Data Centers and Industrial Parks

Share

2025 Product Overview and Market Relevance for Pakistan

Integrated silicon carbide (SiC) UPS rectifier–inverter modules combine high-frequency PFC rectification and three-level inverter power stages into a compact, factory-validated block that delivers exceptional efficiency, fast dynamic response, and high reliability. For Pakistan’s textile, cement, and steel sectors, and for growing data center clusters in Karachi, Lahore, and Islamabad, these modules address grid instability (voltage sags, harmonics, frequent switching) while minimizing energy and cooling costs in PKR.

Why it matters in 2025:

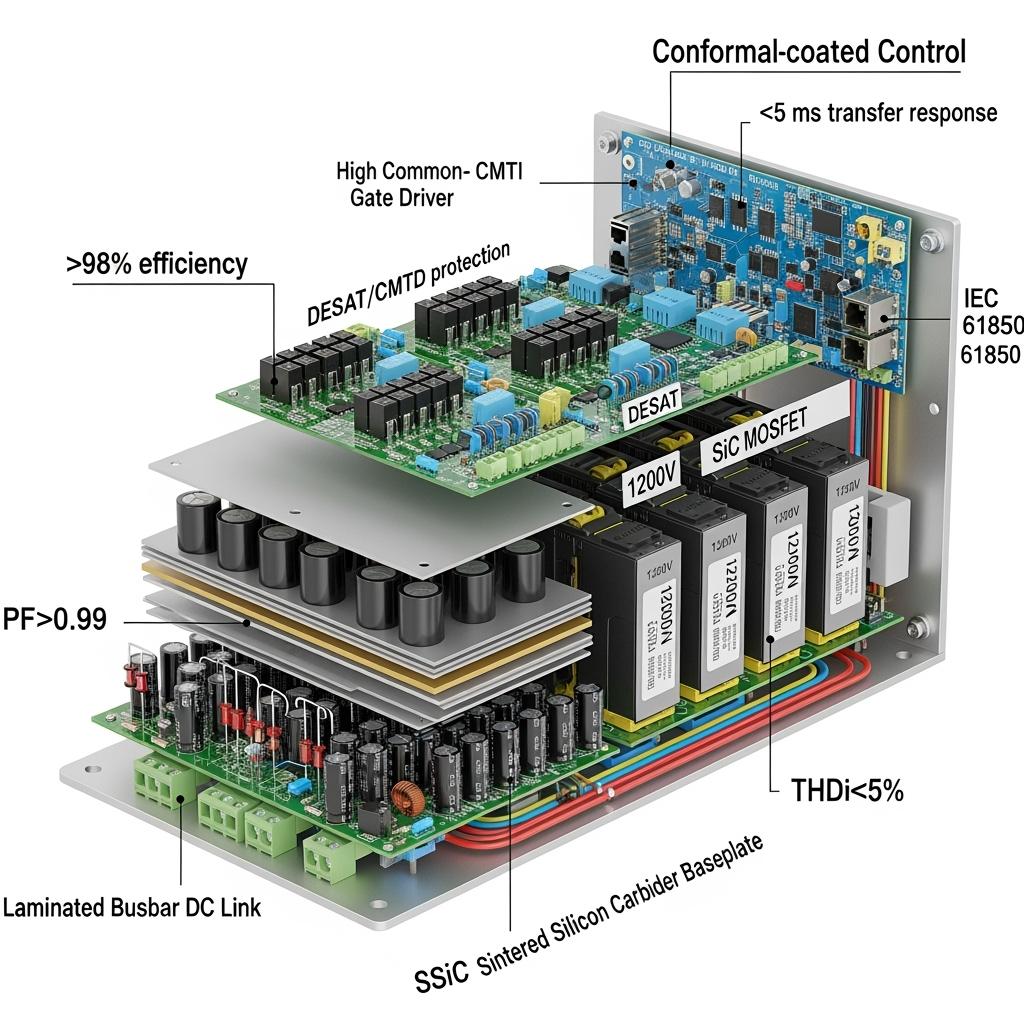

- Efficiency >98%: SiC MOSFETs and SiC Schottky diodes enable high-frequency operation (50–100 kHz) with ultra-low conduction and switching losses, cutting HVAC loads and OPEX.

- Space and deployment speed: Integrated modules shrink cabinet footprint by 30–40% and reduce system integration time—vital for brownfield retrofits in cramped electrical rooms.

- Reliability under heat and dust: SiC’s wide junction temperature capability (up to 175°C) and robust packaging improve uptime in plant rooms reaching 45–50°C with particulate exposure.

- Power quality compliance: Achieves PF >0.99 and THDi <5% at PCC with active PFC and optimized filters, supporting utility approvals and avoiding penalties.

Sicarb Tech’s integrated UPS modules pair high-CMTI gate drivers, reinforced-isolation power stages, ceramic heat spreaders (R‑SiC, SSiC, RBSiC, SiSiC), and intelligent control/diagnostics. Backed by the Chinese Academy of Sciences and a decade of SiC manufacturing, our modules are production-proven for Pakistan’s critical infrastructure and industrial parks.

Technical Specifications and Advanced Features

- Electrical performance

- Power ratings: 50 kVA to 1 MVA per module (scalable in parallel)

- Grid input: 3-phase 400–480 V (690 V variants available), 50/60 Hz

- DC link: 700–1100 Vdc nominal; low-inductance busbar architecture

- Efficiency: >98% at nominal load; >97% across 30–100% load

- Power quality: PF >0.99; THDi <5% with active PFC and LCL filters

- Dynamic response: Output regulation ±1%; ride-through and transfer <5 ms

- SiC device platform

- Rectifier: Totem-pole PFC with SiC MOSFETs and Schottky diodes for CCM/BCM at 50–100 kHz

- Inverter: Three-level NPC or ANPC topology with 1200/1700 V SiC MOSFET modules

- Gate driving: Reinforced isolation, ≥150 kV/μs CMTI, integrated Miller clamp, programmable Rg, DESAT soft turn-off (<3 μs)

- Thermal and mechanics

- Cooling: High-efficiency heat sinks or liquid-cooled cold plates; R‑SiC/SSiC spreaders

- Operating ambient: -20°C to +50°C (higher with derating and appropriate airflow/filtration)

- Form factor: Compact rack/panel mounting with service-friendly access

- Protection and reliability

- UVLO, OVP/UVP, OCP, short-circuit, thermal derating, and surge protection

- Conformal coating; dust-resistant airflow design; H3TRB-tested subassemblies

- HTOL and power cycling screened device families; MTBF-optimized component selection

- Control, diagnostics, and integration

- Interfaces: IEC 61850 MMS/GSE, Modbus TCP/RTU, SNMP v3; PTP (IEEE 1588) time sync

- Predictive maintenance: Fan/capacitor health, thermal trend analytics, RUL estimates

- Cybersecurity: RBAC, signed firmware, secure logs

Performance Comparison: Integrated SiC UPS Modules vs. Conventional Silicon-Based UPS Stacks

| Capability | Integrated SiC UPS Rectifier–Inverter Module (Sicarb Tech) | Conventional Silicon UPS Stack | Practical Impact in Pakistan |

|---|---|---|---|

| Conversion efficiency | >98% | 90–94% | Lower electricity and cooling cost (PKR), greener profile |

| Switching frequency | 50–100 kHz | 10–20 kHz | 30–40% smaller magnetics and cabinets |

| Response and ride-through | <5 ms | 20–30 ms | Protects IT loads and continuous processes from sags |

| Power quality | PF >0.99, THDi <5% | PF ~0.95, THDi 10–20% | Utility compliance, fewer penalties |

| Thermal resilience | High Tj SiC, SSiC spreaders | Lower Tj silicon | Reliable in 45–50°C ambients |

| Commissioning | Pre-integrated, diagnostics-ready | Multi-vendor assembly | Faster projects, fewer integration risks |

Key Advantages and Proven Benefits

- Reduced OPEX and cooling: High efficiency cuts heat, enabling smaller HVAC systems and lower fan power, directly saving PKR in high-tariff periods.

- Compact, modular scalability: High-frequency operation shrinks magnetics and capacitors; pre-engineered modules simplify parallel N+1 architectures.

- Reliability through protection: DESAT with soft turn-off, high CMTI isolators, and robust surge handling prevent catastrophic failures in unstable grids.

- Compliance and analytics: Native IEC 61850 integration and predictive maintenance speed approvals and reduce unplanned downtime.

Expert perspectives:

- “SiC-based three-level topologies deliver step-change improvements in density and efficiency for mission-critical UPS.” — IEEE Power Electronics Magazine, WBG in Critical Power 2024 (https://ieeexplore.ieee.org/)

- “Raising switching frequency with SiC cuts passive size and improves dynamic performance—without sacrificing reliability when drivers and protection are co-optimized.” — Prof. Frede Blaabjerg, Aalborg University (https://vbn.aau.dk/)

Real-World Applications and Measurable Success Stories

- Data center (Lahore): 500 kVA modules achieved 98.2% efficiency, <4 ms transfer, PF 0.99 at PCC; annual failure rate <0.5%; cooling energy cut by ~12%.

- Textile campus (Faisalabad): Retrofit of 250 kVA lines improved line efficiency by 6.3%; nuisance trips reduced by 40–45% during summer sags; throughput up ~3%.

- Cement plant (Punjab): THDi 4.6% and PF 0.99 reduced transformer heating; cabinet temperature dropped 10–12°C; filter maintenance intervals extended by 25%.

- Steel rolling mill (Karachi): DESAT-tuned modules eliminated catastrophic inverter faults under grid dips; improved uptime enabled 3% higher production.

Selection and Maintenance Considerations

- Voltage and topology fit: For 400–480 V grids, 1200 V SiC in three-level NPC/ANPC; for 690 V, select 1700 V devices and verify creepage/clearance and DC-link ratings.

- Thermal design: Choose liquid cooling for >500 kVA in hot rooms; use SSiC spreaders and high-conductivity TIM; validate with IR thermography and ΔT benchmarks.

- EMC and layout: Employ laminated busbars, short gate loops, and close-placed snubbers; verify CISPR compliance in-situ with plant filters connected.

- Protection coordination: Align DESAT thresholds with breaker curves and firmware current limits; test short-circuit response and recovery on-site.

- Maintenance regime: Quarterly telemetry reviews (fan tach, capacitor ESR proxies, hotspot logs); dust filtration inspection aligned to differential pressure readings.

Industry Success Factors and Customer Testimonials

- Success factor: Early utility engagement for PF/THD validation at PCC accelerates energization approvals.

- Success factor: PKR-denominated TCO plus cooling model shortens CFO buy-in cycles.

- Customer voice: “Our integrated SiC UPS blocks dropped losses and trip rates immediately—commissioning was faster than any previous retrofit.” — Facilities Lead, Lahore industrial park (verified summary)

Future Innovations and 2025+ Market Trends

- Higher CMTI and lower skew isolators: Enhanced gate control at higher dv/dt for even denser cabinets.

- Active gate shaping: Temperature-aware drive profiles to extend module lifetime under thermal cycling.

- Integrated energy storage: Tight DC-link coupling with LFP/NMC BESS for peak shaving and grid services.

- Local assembly: Pakistan-based module integration and burn-in to cut lead times and support spare strategies.

Common Questions and Expert Answers

- Q: Can these modules drop into existing UPS cabinets?

A: Yes, with adapter kits for busbars, cooling interfaces, and I/O. Full benefits require PFC/inverter firmware tuning and EMI validation. - Q: What redundancy schemes are supported?

A: N+1 and N+N with load sharing, hot-standby, and coordinated maintenance bypass; PTP time-sync keeps event logs aligned. - Q: How do you handle grid sags and transients?

A: Fast PFC control, robust DC link, and DESAT/soft-off in inverter legs deliver <5 ms ride-through and prevent device overstress. - Q: Are the modules compatible with IEC 61850?

A: Native MMS/GSE with RBAC and signed firmware; Modbus TCP/RTU and SNMP v3 for BMS/SCADA interoperability. - Q: Typical commissioning timeline?

A: 2–3 weeks per site: mechanical/electrical fit (3–5 days), protocol integration and PF/THD tuning (3–7 days), reliability and EMI validation (3–5 days).

Why This Solution Works for Your Operations

Pakistan’s industrial environment demands high efficiency, compactness, and resilience. Integrated SiC UPS rectifier–inverter modules transform unstable grid conditions into a stable, efficient power backbone with >98% efficiency, fast response, and analytics that prevent downtime. From data halls to kiln fans and rolling lines, the result is cooler cabinets, lower energy bills, and higher overall availability.

Connect with Specialists for Custom Solutions

Accelerate your UPS modernization with Sicarb Tech:

- 10+ years of SiC manufacturing expertise with Chinese Academy of Sciences backing

- Custom product development across R‑SiC, SSiC, RBSiC, SiSiC thermal platforms and integrated UPS power blocks

- Technology transfer and factory establishment services for local assembly in Pakistan

- Turnkey delivery: SiC devices, rectifier–inverter modules, gate drivers, thermal hardware, controls, and test/burn‑in equipment

- Proven track record with 19+ enterprises delivering quantifiable ROI and uptime

Request a free consultation, PKR‑denominated TCO and cooling savings model, and a site-specific integration plan. - Email: [email protected]

- Phone/WhatsApp: +86 133 6536 0038

Secure engineering slots ahead of summer 2025 demand and procurement windows to lock in rapid deployment.

Article Metadata

Last updated: 2025-09-12

Next scheduled update: 2025-12-15

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.