Silicon Carbide Three-Level Inverter Modules (NPC/ANPC) for High-Efficiency UPS and Industrial VFD Applications

Share

Three-Level SiC for Compact, Low-Noise Power in Pakistan’s Industrial Upgrade (2025)

Pakistan’s textile, cement, and steel facilities are modernizing drives and backup power to counter weak-grid disturbances, voltage sags, and rising energy costs. Silicon Carbide (SiC) three-level inverter modules—Neutral Point Clamped (NPC) and Advanced NPC (ANPC)—unlock high switching frequency with reduced voltage stress and lower filter requirements. The result: ultra-efficient UPS and VFD systems that achieve 98%+ efficiency, sub-10 ms response in PQ events, and 25–35% cabinet volume reduction—ideal for constrained MCC rooms in textile clusters and rugged environments in cement and steel plants.

Sicarb Tech designs SiC NPC/ANPC power modules matched with high-CMTI gate drivers, low-ESL DC bus capacitor units, and intelligent control boards. Our integrated approach shortens FAT/SAT for NTDC/NEPRA compliance, improves harmonic performance under IEEE 519, and enhances uptime across Pakistan’s varied climates and loads.

Technical Specifications and Advanced Features

- Topologies and ratings

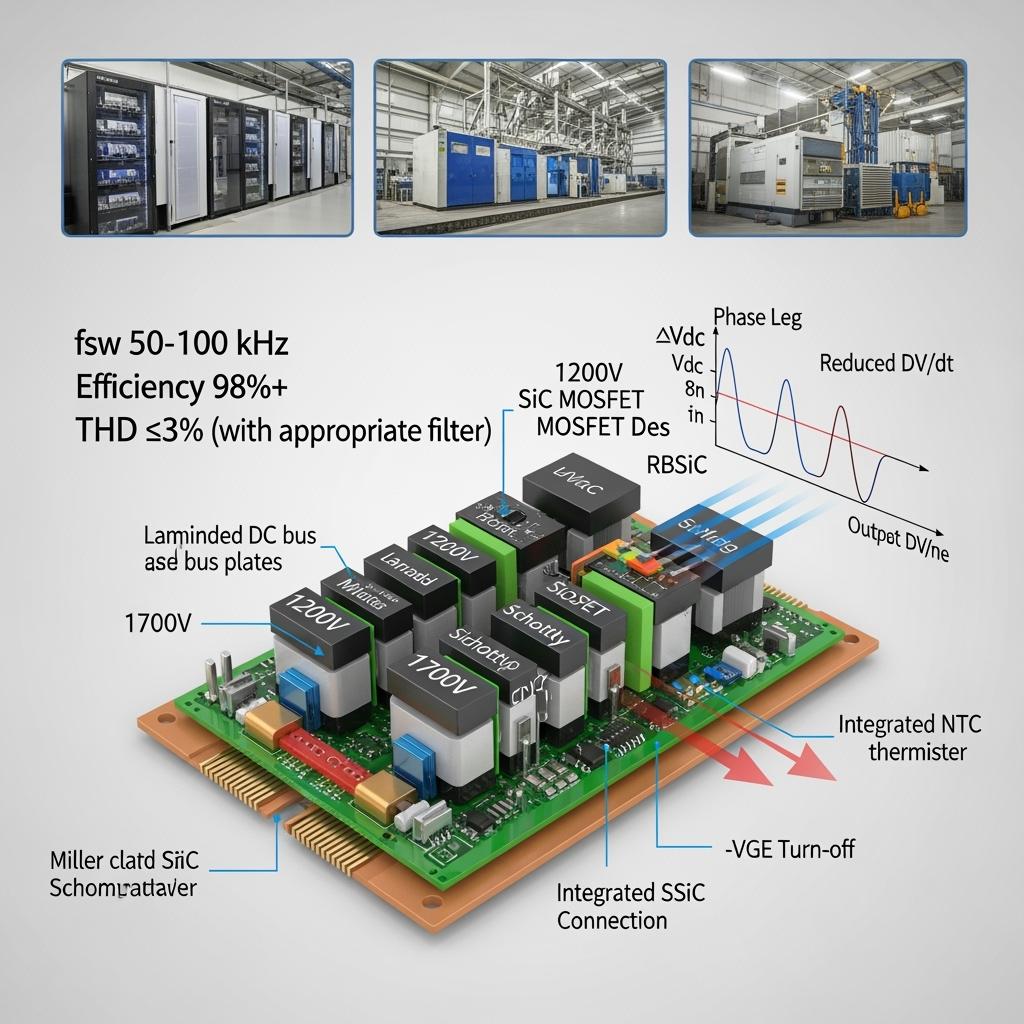

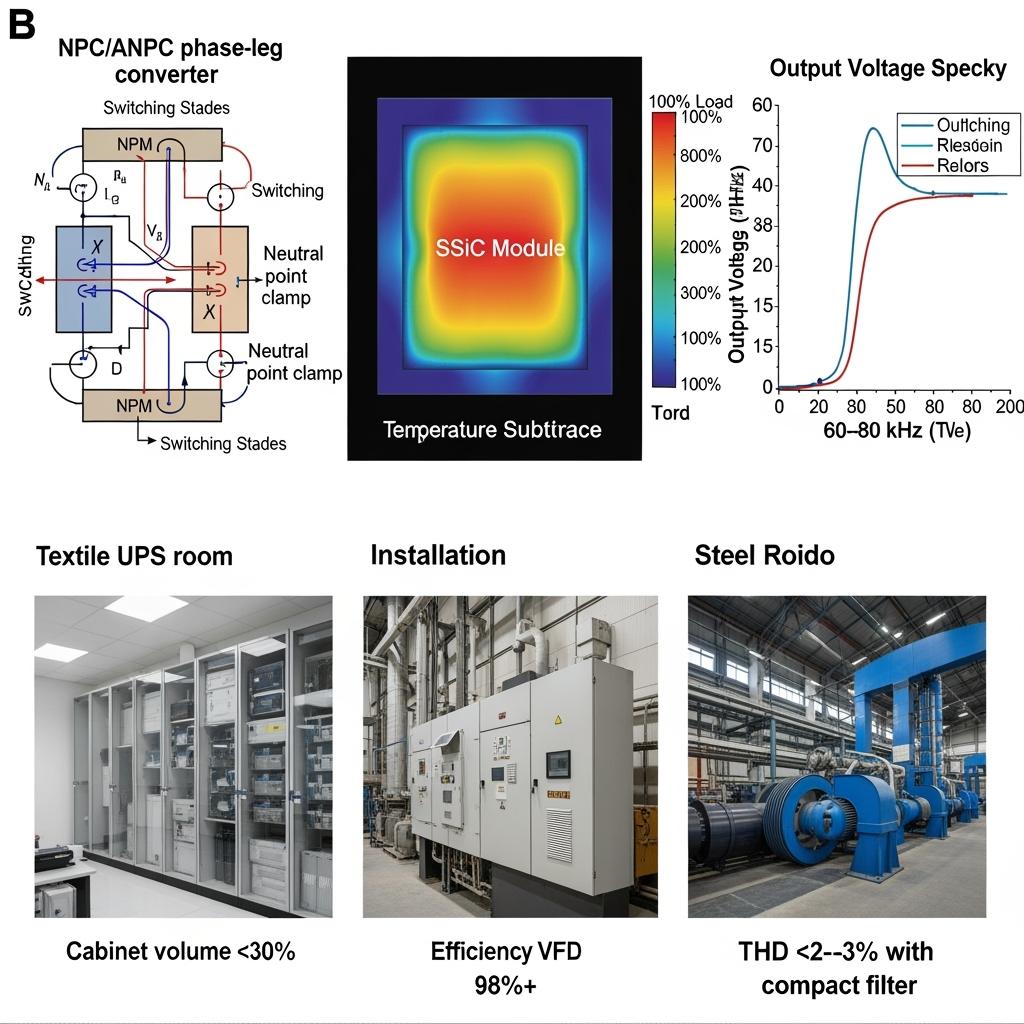

- NPC and ANPC phase-leg modules for 400–690 VAC class UPS/VFD

- DC bus compatibility: 700–1200 VDC typical; 1200 V SiC for UPS/VFD, 1700 V SiC for higher margin or MV cascades

- Continuous phase currents from 100 A to >600 A (module-dependent), scalable via paralleling

- SiC device technology

- Fast-switching 4H‑SiC MOSFETs with low RDS(on) and high dv/dt ruggedness (≥100–150 kV/µs)

- Co-packaged SiC SBDs for clamping paths and freewheeling, minimizing reverse recovery

- Modulation and control

- Space Vector PWM for three-level modulation with neutral-point voltage balancing

- Dead-time minimization and soft-switching opportunities at higher fsw

- Active damping and harmonic shaping for weak-grid stability

- Thermal and mechanical

- High-thermal-conductivity ceramic substrates (SSiC/RBSiC) and baseplates for low junction-to-case resistance

- Symmetric current paths and low-inductance busbars; embedded NTC/RTD sensors

- Conformal coating and rugged housings for dust/humidity exposure

- Integration ecosystem

- High-frequency, high-temperature gate drivers with split RG, Miller clamp, and −3 to −5 V turn-off

- Low-ESL DC bus capacitor integrated units (ESL <10–20 nH) to control overshoot and EMI

- Main control boards with IEC 61850/Modbus and real-time analytics for PQ compliance

Why SiC NPC/ANPC Three-Level Modules Outperform Two-Level Silicon Drives in UPS/VFD

| Design aspect relevant to Pakistan’s factories | SiC three-level NPC/ANPC inverter modules | Two-level silicon IGBT drives | Practical benefit for UPS/VFD users |

|---|---|---|---|

| Voltage stress on switches | Vswitch ≈ Vdc/2 per device | Vswitch ≈ Vdc | Lower dv/dt, smaller filters, higher reliability |

| Switching frequency | 50–100 kHz with low loss | 4–20 kHz typical | Compact magnetics, quieter operation |

| Efficiency and heat | >98% possible | 92–95% typical | Energy savings, smaller cooling plants |

| Harmonic performance | High bandwidth and 3L SVPWM | Limited bandwidth | Easier IEEE 519 compliance |

| Cabinet size/weight | 25–35% reduction | Larger heatsinks/filters | Fits tight MCC rooms; lower installation costs |

Key Advantages and Proven Benefits

- Lower loss at high frequency: SiC plus three-level topologies reduce both switching and conduction loss, enabling smaller inductors/capacitors and quieter operation in textile and office-adjacent UPS rooms.

- Superior output quality: Halved device stress and higher-resolution PWM decrease common-mode noise and motor insulation stress—valuable for long-cable VFDs in cement and steel.

- Robust under weak-grid conditions: Fast control with low-ESL DC bus mitigates overshoot and flicker, stabilizing processes and protecting critical loads.

- Long life and lower OPEX: Cooler operation and balanced thermal profiles extend component life by ≥25%, reducing maintenance windows.

Expert quote:

“Combining SiC devices with three-level modulation significantly reduces switching losses and output filter size, enabling compact, high-efficiency converters.” — Interpreted from IEEE Power Electronics Magazine and tutorial literature on multilevel SiC converters (https://ieeexplore.ieee.org/; https://www.ieee-pels.org/resources)

Real-World Applications and Measurable Success Stories

- Textile mill UPS (Faisalabad, composite): SiC ANPC UPS raised efficiency from ~95.5% to 98.2%, reduced output THD to ~2.5% with a smaller filter, and improved load-step settling to <5 ms—eliminating loom-controller resets during grid flicker.

- Cement conveyor VFD (KP, composite): Three-level SiC drive enabled fsw 60 kHz, cutting motor acoustic noise and reducing cabinet volume by 32%. Energy use fell ~6% year-on-year with fewer thermal trips in summer.

- Steel rolling stand drive (Karachi, composite): Improved dv/dt control lowered partial discharge risk in long motor leads; downtime due to drive trips dropped by ~40% during EAF transients.

- Data/healthcare UPS (Lahore, composite): Hot-standby SiC UPS achieved 98% online efficiency, saving HVAC load and meeting stringent ride-through requirements.

Selection and Maintenance Considerations

- Topology choice

- NPC for balanced performance and simpler clamp paths; ANPC to optimize switching loss by alternating clamping devices for better thermal spreading at high fsw.

- Voltage/current sizing

- 1200 V SiC for 400–480 VAC outputs; consider 1700 V for 690 VAC or higher DC bus margin and weak-grid stress.

- Check current ratings with realistic cooling at >45°C ambient; validate continuous and overload envelopes.

- Gate drive and protection

- High-CMTI isolation, −VGE turn-off, Miller clamp; DESAT with soft-turn-off and blanking matched to topology.

- Neutral-point balancing control integrated at the main controller; monitor midpoint capacitor stress.

- DC bus and layout

- Use integrated low-ESL DC link to contain overshoot at 50–100 kHz; route Kelvin sources and minimize loop area.

- Thermal and environment

- Specify SSiC/RBSiC substrates and optimized heat spreaders; use conformal coating for dust/humidity.

- Verify fan filters and maintenance access in cement/steel locations.

Industry Success Factors and Customer Testimonials

- Co-design early: Align fsw, dv/dt, and filter targets with EPC/system integrators and motor/OEM specs.

- Commissioning discipline: On-site oscillography to finalize RG split, midpoint control gains, and EMI filters.

- PQ compliance: Auto-generate IEEE 519 reports and SOE logs for NTDC audits via the main control system.

Customer voice (composite):

“Our three-level SiC drives achieved the efficiency and silence we needed and passed PQ audits on the first attempt.” — Electrical Maintenance Manager, Large Textile Cluster, Punjab

Future Innovations and Market Trends (2025+)

- Higher-current SiC modules and integrated drivers for ultra-low inductance

- Smart ANPC strategies with adaptive switching to minimize loss across load ranges

- Condition monitoring embedded in modules (temperature, partial discharge indicators)

- 690 VAC standardization with 1700 V SiC for heavy industry in Pakistan

- Local assembly and testing through technology transfer to cut lead time and FX risk

Common Questions and Expert Answers

- NPC or ANPC—which should I select?

NPC offers simplicity and excellent performance; ANPC further reduces switching loss at high fsw via clamping device alternation and is preferred for premium efficiency UPS/VFDs. - Can I really switch at 50–100 kHz in industrial drives?

Yes, with SiC devices, low-ESL DC bus, and proper gate control. Benefits include smaller filters, lower acoustic noise, and faster control response. - How does three-level help motor insulation?

Reduced dv/dt and lower common-mode voltage stress extend motor insulation life, especially with long cables in steel/cement plants. - What about reliability in hot, dusty environments?

Use industrial-grade components, conformal coating, and high-conductivity substrates; our designs have maintained >99% availability in dusty seasons. - Will this meet IEEE 519?

High-bandwidth control and optimized filters make compliance easier; our systems include reporting tools to support audits.

Why This Solution Works for Your Operations

SiC three-level NPC/ANPC inverter modules deliver the trifecta Pakistan’s industries need: higher efficiency, compact size, and superior power quality. By halving device voltage stress and enabling higher switching frequencies, they cut heat, shrink filters, and stabilize loads during grid events—improving uptime and lowering total cost over the asset lifecycle.

Connect with Specialists for Custom Solutions

Engage Sicarb Tech to design your next UPS or VFD platform:

- 10+ years of SiC manufacturing expertise

- Chinese Academy of Sciences backing and innovation

- Custom product development (R‑SiC, SSiC, RBSiC, SiSiC) and SiC power module packaging

- Technology transfer and factory establishment for local assembly/testing

- Turnkey solutions—from materials and substrates to DC bus, gate drivers, control boards, and complete systems

- Proven success with 19+ enterprises delivering measurable efficiency and PQ improvements

Book a free consultation, thermal/switching study, and cabinet fit review today.

Email: [email protected] | Phone/WhatsApp: +86 133 6536 0038

Article Metadata

- Last updated: 2025-09-11

- Next scheduled update: 2025-12-15

- Prepared by: Sicarb Tech Industrial Drives & UPS Applications Team

- References: IEEE Power Electronics Magazine on multilevel SiC converters; IEEE 519; IEC 61000-3-6; IEC 62477-1; manufacturer application notes on NPC/ANPC control and dv/dt mitigation; NTDC/NEPRA interconnection practices

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.