1700V/1200V Silicon Carbide MOSFET Devices for High-Switching-Frequency Inverters, EV Chargers, and Grid-Tied Converters

Share

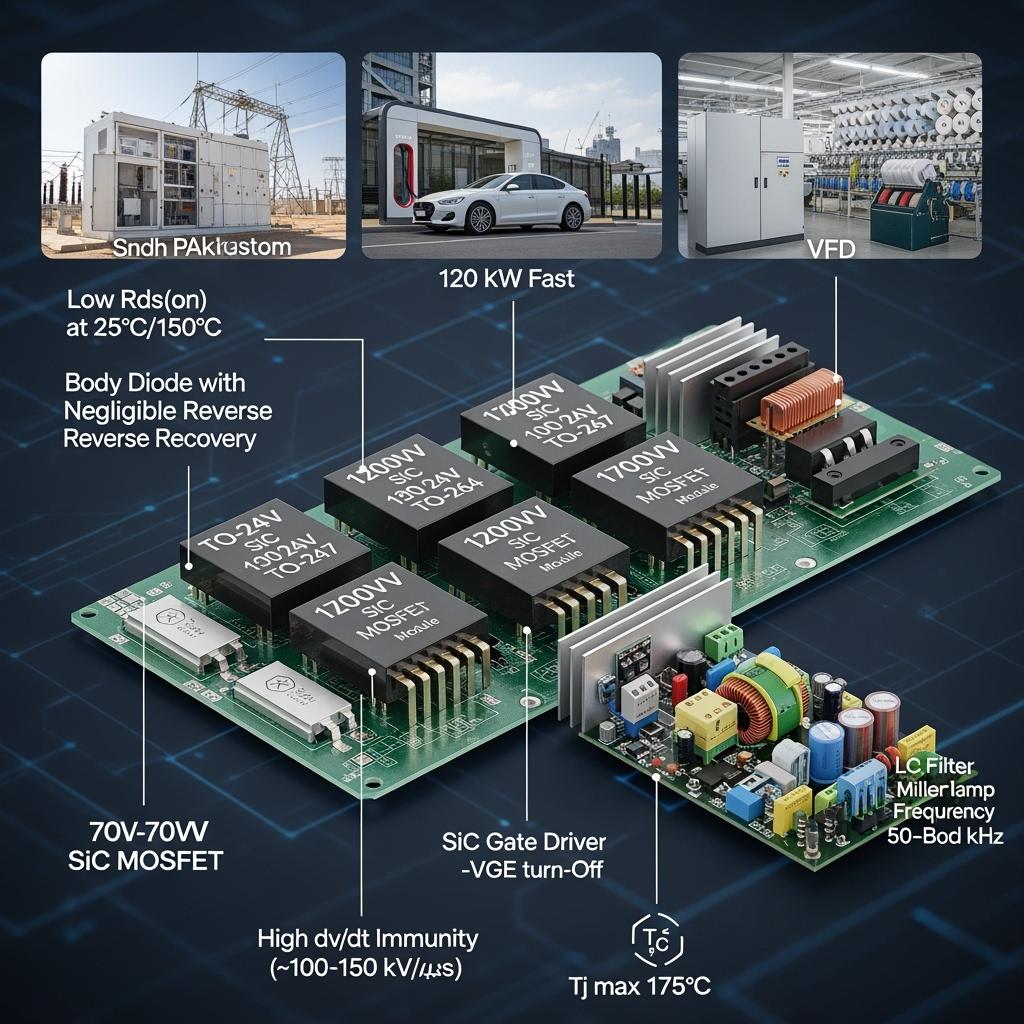

High-Efficiency SiC Switching for Pakistan’s Power Quality and Electrification Demands in 2025

Pakistan’s textile mills, cement kilns, and steel rolling lines are upgrading drives, rectifiers, and grid-interface systems while wind and solar additions accelerate in Sindh and Balochistan. To stabilize weak nodes and improve efficiency under rising tariffs, power converters require faster switching, lower losses, and higher temperature tolerance. 1700V/1200V Silicon Carbide (SiC) MOSFET devices enable compact, high-frequency inverters, fast EV chargers, and robust grid-tied converters—boosting system efficiency beyond 98%, improving dynamic response, and reducing cabinet footprint by 25–35%.

Sicarb Tech’s 4H‑SiC MOSFET portfolio is engineered for SVG/STATCOM, APF, PV/wind inverters, industrial VFD front-ends, UPS, and high-power DC fast chargers. With low RDS(on) per die, high dv/dt capability, and 175°C junction operation, our devices maintain performance in hot, dusty environments and during grid disturbances. Backed by the Chinese Academy of Sciences, we provide device application notes, gate-drive co-design, and module integration to shorten FAT/SAT and streamline NTDC/NEPRA approvals.

Technical Specifications and Advanced Features

- Voltage classes and die options

- 1200 V and 1700 V 4H‑SiC MOSFETs for 600–1100 VDC buses and MV cascades

- Typical RDS(on) per die: from <20 mΩ (1200 V) and <45 mΩ (1700 V) at 25°C; characterized up to 150°C

- Avalanche-rugged variants available for demanding grid events

- High-frequency switching

- Efficient operation at 50–100 kHz (and beyond with proper design)

- Low output capacitance (Coss) and minimal gate charge (Qg) reduce switching loss and enable smaller magnetics

- Body diode and reverse recovery

- Intrinsic body diode with negligible reverse recovery charge; optimized for hard-commutation with SiC SBD co-design

- Suited for totem-pole PFC, interleaved DC-DC, and grid-tied H-bridges

- Robustness and reliability

- Junction temperature range −55°C to 175°C; high-temperature gate stability

- High dv/dt ruggedness (≥100–150 kV/µs) with recommended gate drive practices

- Short-circuit withstand and DESAT-compatible soft-turn-off strategies

- Packaging and integration

- Discrete TO packages and power modules (half-bridge/full-bridge/NPC) with low inductance

- Compatible with high-thermal-conductivity substrates (SSiC/RBSiC ceramics) for >8 kW/L system density

- Application support for IEC 61850-enabled control and PQ analytics at system level

Why 1700V/1200V SiC MOSFETs Outperform Silicon IGBTs and Superjunction MOSFETs in Industrial Pakistan

| Performance factor in high-switching power stages | SiC MOSFET devices (1200 V / 1700 V) | Silicon IGBT / SJ MOSFET alternatives | Operational impact in Pakistan |

|---|---|---|---|

| Efficiency at 50–100 kHz | Very high (low switching + conduction loss) | Moderate; IGBTs limited by tail current | 5–7% system energy savings; lower tariffs burden |

| Thermal headroom | TJ up to 175°C, lower derating | TJ typically ≤125°C | Reliable in >45°C ambient at cement/steel sites |

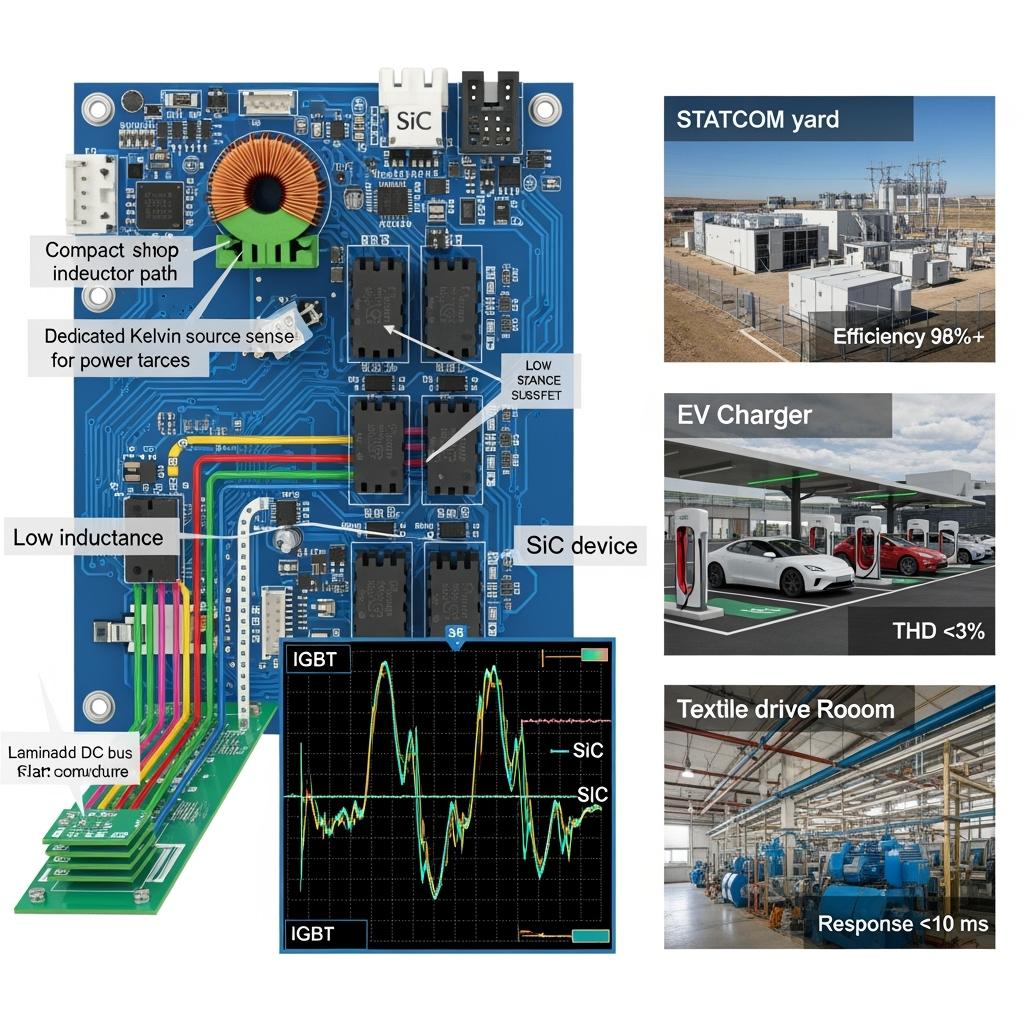

| Dynamic response | Fast dv/dt, low Qg/Coss | Slower switching, larger filters | <10 ms var response, smaller L/C components |

| Size and weight | Higher power density, smaller magnetics | Larger heat sinks and filters | 25–35% cabinet volume reduction |

| Harmonic performance | High bandwidth enables better PQ control | Limited bandwidth | Easier IEEE 519 alignment; fewer penalties |

Key Advantages and Proven Benefits

- High efficiency at high frequency: Lower switching and conduction losses allow compact filters and higher bandwidth control, critical for SVG/STATCOM and APF performance.

- Thermal resilience: Maintain performance in hot, dusty environments with reduced cooling requirements and longer service intervals.

- Robust grid interaction: High dv/dt capability, fast protection, and avalanche options improve survivability during sags, surges, and weak-grid oscillations.

- Lower total cost of ownership: Energy savings, reduced HVAC, smaller enclosures, and less maintenance drive faster ROI.

Expert quote:

“Wide-bandgap devices such as SiC enable higher switching frequencies with superior efficiency and thermal performance—key to compact, fast-responding grid converters.” — Interpreted from IEEE Power Electronics Society technology trend insights (https://www.ieee-pels.org/resources)

Real-World Applications and Measurable Success Stories

- Sindh wind farm STATCOM (composite): Upgrading to 1700 V SiC MOSFET modules lifted switching from 20 to 60 kHz and improved reactive response to <10 ms; chain efficiency reached 98.4%, with fewer filter components.

- Faisalabad textile VFD front-ends: 1200 V SiC totem-pole PFC achieved PF >0.99 and cut THD to ~3%, reducing penalties and shrinking cabinet depth by 30%.

- Karachi industrial EV fast charging hub: 120–180 kW chargers using 1200 V SiC reduced losses by ~3–4 percentage points, enabling passive cooling in moderate climates and improving uptime.

- KP cement auxiliaries: SiC-based APFs maintained THD within IEEE 519 during dust season; maintenance intervals extended by ~25% thanks to cooler operation.

Selection and Maintenance Considerations

- Device selection

- Choose 1200 V for 400–800 VDC buses (EV chargers, industrial drives, PV inverters); 1700 V for 1–1.2 kV buses, STATCOM/APF, and MV stacks

- Evaluate RDS(on) vs die area and thermal budget at operating temperature

- Gate drive and protection

- Use split RG, Miller clamp, and −3 to −5 V turn-off; ensure CMTI ≥100–150 kV/µs

- Implement DESAT detection with soft-turn-off; coordinate with short-circuit SOA

- Layout and magnetics

- Minimize loop inductance with laminated busbars and Kelvin source routing

- Right-size magnetics for 50–100 kHz to capture SiC benefits without acoustic issues

- Thermal management

- Pair with high-conductivity substrates and heat spreaders; validate under >45°C ambient

- Monitor temperature with NTC/RTD and design for predictable thermal cycling

- Compliance and audits

- Integrate PQ monitoring to demonstrate IEEE 519/IEC 61000-3-6 alignment

- Prepare evidence packs for NTDC/NEPRA using synchronized event logging at system level

Industry Success Factors and Customer Testimonials

- Early co-design with EPCs/integrators for switching frequency, EMI targets, and grid-code parameters

- Prototyping and on-site oscillography to finalize RG values and blanking times

- Localized spares and training to improve MTTR in remote wind/PV sites

Customer voice (composite):

“SiC MOSFETs let us shrink cabinets while improving efficiency and passing PQ audits on the first inspection.” — Electrical Projects Lead, Large Textile Complex, Punjab

Future Innovations and Market Trends (2025+)

- 200 mm SiC wafer scaling: Lower device cost and higher current ratings

- Advanced trench/planar SiC MOSFETs with improved channel mobility and lower RDS(on) at 150°C

- Co-packaged drivers and sensors for ultra-low inductance and smarter protection

- Grid-forming and hybrid STATCOM+BESS architectures leveraging SiC’s bandwidth

- Increased local assembly in Pakistan through technology transfer to cut lead times and FX exposure

Common Questions and Expert Answers

- Which voltage class should I choose?

1200 V for 400–800 V buses (EV chargers, PV, VFD front-ends), 1700 V for 1–1.2 kV buses and utility power quality systems. - What switching frequency is practical in harsh environments?

50–100 kHz is typical with proper gate drive, layout, and thermal design; higher is possible in specific topologies. - Do I still need SiC Schottky diodes with SiC MOSFETs?

Often beneficial in hard-commutation legs to minimize losses and EMI; totem-pole PFC can rely on MOSFET body diodes with careful control. - How do I manage dv/dt-induced issues?

Use high-CMTI drivers, optimized layout, negative gate bias, and proper snubbing; validate with time-domain measurements. - Can SiC help with IEEE 519 compliance?

Yes—higher control bandwidth and lower ripple enable better harmonic performance; combine with APF/SVG strategies for best results.

Why This Solution Works for Your Operations

SiC MOSFETs deliver the high-frequency efficiency and thermal robustness needed to stabilize weak grids, cut energy costs, and reduce footprint in Pakistan’s industrial and renewable plants. When combined with proper gate driving, DC bus integration, and standards-based monitoring, they provide faster approvals, higher uptime, and lower lifecycle cost than silicon alternatives.

Connect with Specialists for Custom Solutions

Accelerate your next converter platform with Sicarb Tech:

- 10+ years of SiC manufacturing expertise

- Chinese Academy of Sciences backing and innovation

- Custom product development across R‑SiC, SSiC, RBSiC, SiSiC materials and device packaging

- Technology transfer and factory establishment services for local assembly and testing

- Turnkey solutions from material processing to finished STATCOM/APF/charger/inverter systems

- Proven results with 19+ enterprises—efficiency gains, faster commissioning, and robust compliance

Request a free device selection review, thermal/switching analysis, and pilot module plan for your application.

Email: [email protected] | Phone/WhatsApp: +86 133 6536 0038

Article Metadata

- Last updated: 2025-09-11

- Next scheduled update: 2025-12-15

- Prepared by: Sicarb Tech SiC Devices & Applications Team

- References: IEEE PELS resources on WBG devices; IEEE 519; IEC 61000-3-6; IEC 62477-1; IEA reports on grid integration; NTDC/NEPRA interconnection practices

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.