High-Frequency, High-Temperature Gate Drivers Optimized for SiC MOSFETs (Isolated, High dv/dt Immunity)

Share

Gate Drive Reliability for Pakistan’s High-Efficiency Converters in 2025

Pakistan’s textile, cement, and steel sectors are accelerating electrification and power quality upgrades while renewable capacity expands in Sindh and Balochistan. To fully realize the efficiency and speed of Silicon Carbide (SiC) MOSFETs in SVG/STATCOM, APF, high-frequency drives, UPS, and industrial power supplies, the gate driver is mission-critical. High-frequency, high-temperature SiC-optimized gate drivers with reinforced isolation and high dv/dt immunity prevent false turn-on, minimize switching losses, and ensure stable operation in >45°C ambient temperatures, dust, and humidity.

Sicarb Tech designs and supplies SiC-optimized gate driving solutions featuring robust isolation, wide common-mode transient immunity (CMTI), precise Miller control, and programmable turn-on/turn-off dynamics. Backed by the Chinese Academy of Sciences, our platforms integrate seamlessly into multilevel topologies and IEC 61850-monitored systems, shortening commissioning cycles for NTDC/NEPRA interconnection and improving long-term reliability.

Technical Specifications and Advanced Features

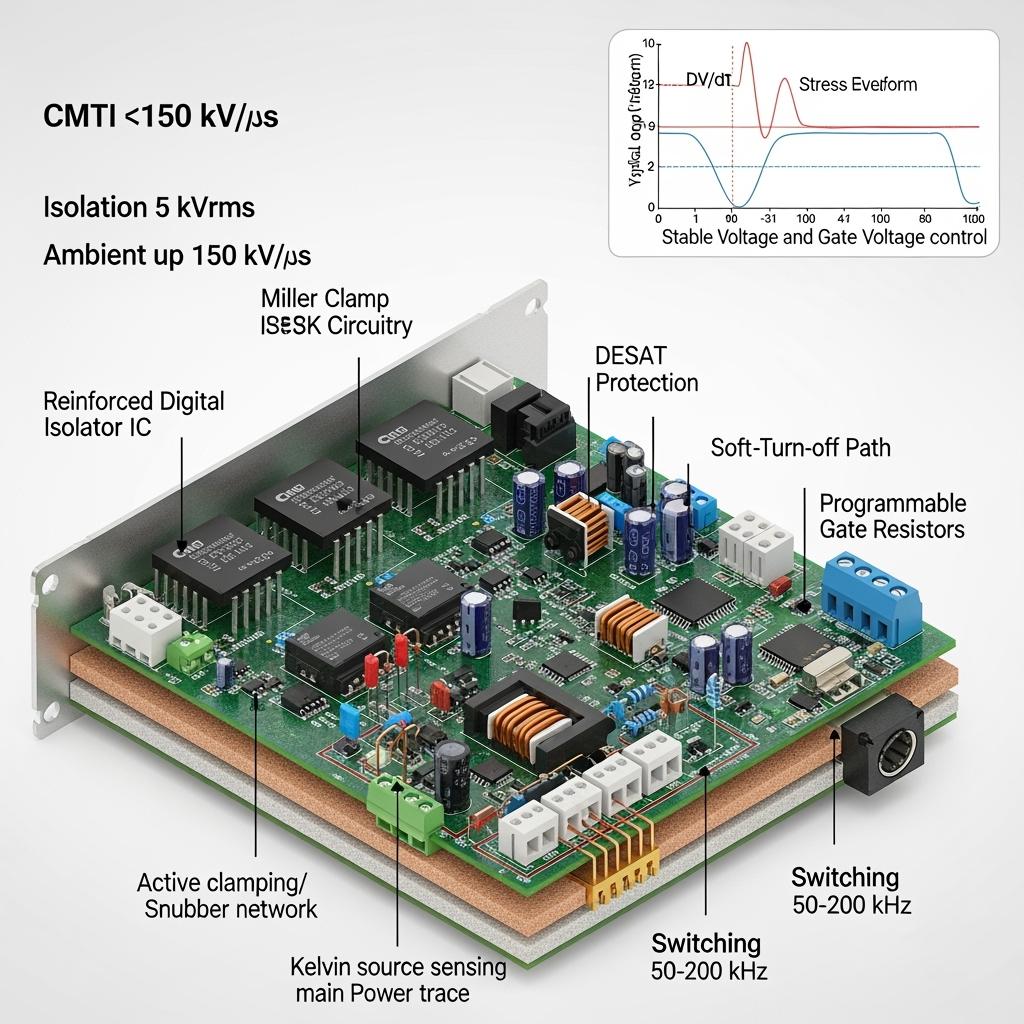

- Isolation and noise immunity

- Reinforced isolation up to 5 kVrms; creepage/clearance designed to IEC 60664-1

- CMTI ≥150 kV/µs to tolerate fast SiC switching edges without data corruption

- Fiber-optic or differential link options for long noisy cable runs in substations and mills

- Gate control and protection

- Programmable gate resistors and split RG (turn-on/turn-off) for EMI and overshoot control

- Miller clamp and negative gate bias (e.g., +18 V / −3 to −5 V) to prevent false turn-on

- DESAT overcurrent protection with soft-turn-off; short-circuit withstand coordination

- Active gate control profiles: di/dt and dv/dt shaping to balance loss and EMI

- Power and thermal

- Isolated bias supply ±18 V class, 3–6 W per channel; UVLO thresholds matched to SiC MOSFET requirements

- Operates in ambient up to 105°C; components rated for junction temperatures aligned with industrial grade

- Efficiency-optimized layout with low parasitic inductance and Kelvin source return

- Timing and diagnostics

- Propagation delay <100 ns with channel-to-channel matching ≤20 ns for multilevel stacks

- Fault latching, event timestamping, and health monitoring via SPI/CAN/optical links

- Ready for integration into IEC 61850 gateways via main control board (system-level interface)

- Compliance and reliability

- Designed to meet IEC 62477-1 (converter safety) and industrial EMC requirements

- Conformal coating options for cement dust and coastal humidity; IP-rated enclosures available at system level

Why SiC-Optimized Gate Drivers Outperform Conventional Drivers in Harsh, High-Switching Environments

| Design focus | SiC-optimized isolated gate driver (this solution) | Conventional IGBT-era driver | Operational impact in Pakistan |

|---|---|---|---|

| dv/dt and CMTI | ≥150 kV/µs CMTI; robust against fast edges | 25–50 kV/µs; prone to false triggers | Stability in weak-grid events and noisy substations |

| Gate control | Split RG, Miller clamp, −Vge turn-off, active control | Fixed RG, limited clamp options | Lower EMI, fewer nuisance trips, better efficiency |

| Protection | DESAT with soft-turn-off, fast short-circuit response | Slower OC detection; harsher turn-off | Protects expensive SiC modules and reduces downtime |

| Thermal rating | Ambient up to 105°C; high-reliability components | 70–85°C typical | Reliable in >45°C ambient and dusty plants |

| Synchronization | Tight delay matching for multilevel topologies | Loose matching | Balanced switching, reduced circulating currents |

Key Advantages and Proven Benefits

- Efficiency and EMI balance at high frequency (50–200 kHz): Programmable gate profiles reduce switching loss without sacrificing EMC.

- Reliability at temperature: Stable operation in hot, dusty cement and steel environments minimizes derating and shutdowns.

- Protection tuned for SiC: Fast DESAT and soft-turn-off reduce device stress during faults and grid events.

- Faster commissioning: Integrated diagnostics and standardized interfaces accelerate FAT/SAT and NTDC/NEPRA acceptance.

Expert quote:

“Gate drivers are the linchpin for realizing SiC’s promise—robust isolation, high CMTI, and precise gate shaping are essential to avoid EMI issues and unlock efficiency gains.” — Interpreted from IEEE Power Electronics Magazine perspectives on WBG gate driving (https://ieeexplore.ieee.org/xpl/RecentIssue.jsp?punumber=6161321)

Real-World Applications and Measurable Success Stories

- SVG/STATCOM in Sindh wind farm (composite): Upgraded to SiC-optimized drivers improved reactive step response to <10 ms and reduced switching losses by ~12%, raising compensation chain efficiency above 98%.

- Textile VFD front-end retrofit in Faisalabad: Gate shaping cut EMI-induced trips by 70% and allowed frequency increase from 20 kHz to 60 kHz, shrinking magnetics by ~25%.

- Steel APF in Karachi: Negative gate bias and Miller clamp eliminated false turn-on during EAF transients; THD stabilized within IEEE 519 limits with fewer filter re-tunes.

- Cement plant auxiliaries in KP: Conformal-coated gate driver assemblies maintained uptime through dust season with <0.5% driver-related failure events over 12 months.

Selection and Maintenance Considerations

- Electrical compatibility

- Match driver output current (2–10 A peak) to device gate charge and desired switching speed

- Select negative gate bias level to suppress Miller turn-on without overstressing gate oxide

- Ensure UVLO thresholds align with MOSFET requirements (+/− rails)

- Isolation and layout

- Choose reinforced isolation for MV stacks; verify creepage/clearance for local pollution degree

- Kelvin source return routing to minimize parasitic inductance and measurement error

- Protection and sensing

- DESAT threshold setting and blanking time tuned to device characteristics and topology (NPC/ANPC/MMC)

- Incorporate NTC/RTD sensing near dies for thermal foldback; ensure fault propagation paths to main controller

- Environmental robustness

- Specify conformal coating and gasketed enclosures in dusty/humid sites

- Validate airflow or liquid cooling paths around drivers and gate resistors

- Lifecycle and spares

- Maintain firmware/config backups; keep calibrated spares for critical feeders

- Plan annual review for parameter tuning as operating profiles evolve

Industry Success Factors and Customer Testimonials

- Early co-design with EPCs/integrators to align switching frequency, EMI targets, and grid compliance

- On-site oscillography during commissioning to finalize RG split, clamp thresholds, and blanking times

- Local training for O&M teams to interpret diagnostics and maintain parameter integrity

Customer voice (composite):

“After adopting SiC-specific drivers, we pushed to higher frequency without EMI penalties and eliminated nuisance trips during grid flicker events.” — Head of Electrical Maintenance, Textile Cluster, Punjab

Future Innovations and 2025+ Market Trends

- Integrated drivers in SiC power modules: Shorter loop inductance, embedded sensing, and smarter protection

- Adaptive gate control using real-time device temperature and current to minimize switching loss dynamically

- Higher CMTI (>200 kV/µs) and digital isolation with lower jitter for MMC-based utility converters

- Cybersecure diagnostics channels to align with IEC 62443 for critical infrastructure

Common Questions and Expert Answers

- What CMTI is recommended for SiC at 50–100 kHz switching?

≥100–150 kV/µs is recommended; our designs target ≥150 kV/µs for margin in weak-grid and EAF environments. - Do I need negative gate bias for SiC MOSFETs?

Often yes, especially in fast-switching or high dv/dt topologies. −3 to −5 V turn-off with Miller clamp reduces false turn-on risk. - How do you set DESAT and blanking time?

We calculate based on device SOA, stray inductance, and topology, then validate with oscilloscope captures during FAT/SAT to ensure soft-turn-off without excessive energy dissipation. - Can these drivers integrate with IEC 61850 systems?

At system level, the main controller aggregates driver telemetry via SPI/CAN/optical and publishes via IEC 61850 MMS/GOOSE with synchronized timestamps. - What about operation in >45°C and dust?

We specify industrial-grade components, conformal coating, and thermal design margins; enclosures achieve IP54–IP65 per site requirements.

Why This Solution Works for Your Operations

SiC gate drivers designed for high dv/dt and temperature unlock the full performance of SiC MOSFETs—higher efficiency, smaller magnetics, and stable dynamics—while protecting devices during faults. In Pakistan’s harsh conditions and weak-grid interconnections, that translates directly to fewer trips, faster approvals, and lower lifetime cost.

Connect with Specialists for Custom Solutions

Partner with Sicarb Tech to co-design the right gate driving strategy for your SVG/STATCOM, APF, VFD front-ends, and UPS:

- 10+ years of SiC manufacturing expertise

- Chinese Academy of Sciences-backed R&D and validation

- Custom product development across R‑SiC, SSiC, RBSiC, SiSiC materials and SiC power modules

- Technology transfer and factory establishment services—from feasibility to commissioning

- Turnkey solutions from material processing and substrates to finished systems and controls

- Proven track record with 19+ enterprises delivering measurable efficiency and PQ gains

Get a free consultation, design review, and on-site commissioning plan.

Email: [email protected] | Phone/WhatsApp: +86 133 6536 0038

Article Metadata

- Last updated: 2025-09-11

- Next scheduled update: 2025-12-15

- Prepared by: Sicarb Tech Application Engineering Team

- References: IEEE Power Electronics Magazine on WBG gate driving; IEC 62477-1; IEC 60664-1; IEEE 519; IEC 61000-3-6; NTDC/NEPRA interconnection practices

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.