High-Frequency SiC Rectifier Bridge Modules for Compact, Low-THD AC-DC Conversion

Share

Product Overview and 2025 Market Relevance

High-frequency silicon carbide (SiC) rectifier bridge modules convert AC to DC with dramatically lower losses and superior high-temperature stability compared to traditional silicon bridges. Built on wide-bandgap SiC diodes with near-zero reverse recovery charge, these modules support higher switching frequencies, smaller magnetics, and cleaner input current—driving compact, efficient power front-ends in Pakistan’s textile, cement, and steel sectors, as well as data centers and financial machine rooms.

In 2025, Pakistan’s industrial users face:

- Mains instability and high ambient temperatures (often 40–45°C in plant rooms)

- Pressure to reduce total harmonic distortion (THD) and improve power factor to protect transformers and meet Grid Code quality expectations

- Space constraints in MCC rooms, UPS rooms, and control cabins

- Escalating electricity tariffs and OPEX pressures

SiC rectifier bridge modules address these challenges by enabling low-THD AC-DC conversion, high power density, and robust operation in dusty, hot environments common to cement kilns, textile mills, and steel rolling support systems—while meeting stringent uptime needs of data centers and finance-sector IT rooms.

Technical Specifications and Advanced Features

Representative specs (customizable to project requirements):

- Voltage ratings: 600–1700 V

- Current ratings: 25–300 A per module (scalable via paralleling)

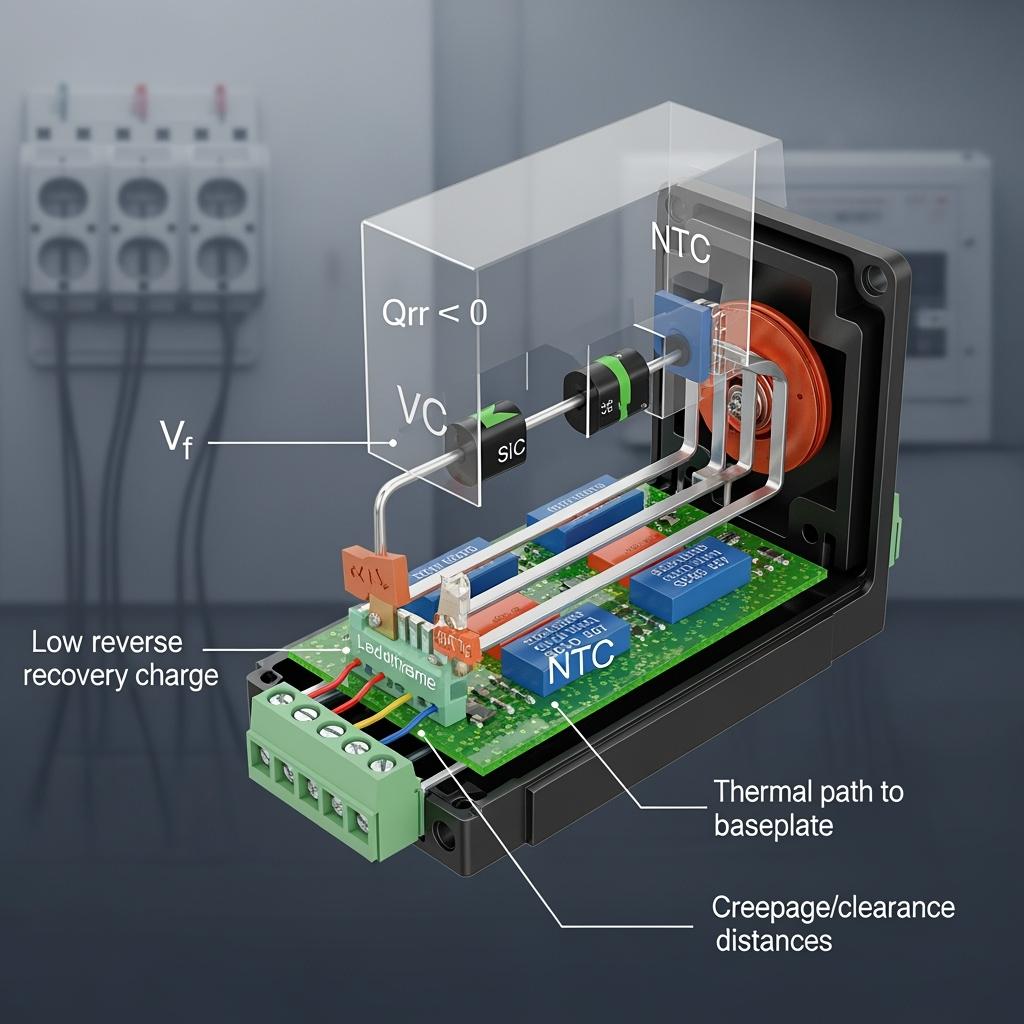

- Diode type: SiC Schottky (Qrr ~ 0), ultra-fast recovery

- Typical forward voltage (Vf): 1.25–1.7 V at rated current

- Switching frequency support: up to 100 kHz front-end operation

- Junction temperature (Tj,max): 175°C (select to 200°C)

- Thermal design: AlN or Si3N4 DBC; low RθJC; optional SSiC heat spreaders

- Package options: 3-phase bridge, single-phase full bridge, dual common-cathode/anode variants

- Integrated sensing: NTC for temperature monitoring; optional current shunt integration

- Protection compatibility: surge-rated with superior thermal stability; supports MOV/TVS coordination

- Compliance targets: IEC 61000-3-2/3 (harmonics/flicker), IEC 62477-1 (safety), IEC 62040 (UPS), aligned with PEC and NTDC Grid Code quality expectations

Advanced features by Sicarb Tech:

- Optimized low-inductance internal layout reduces overshoot and EMI

- High-CMTI co-engineered driver interfaces when used in boost PFC stages

- Rugged packaging options with conformal coating and dust-protected housings for cement/textile sites

- Optional integrated snubber network footprints to simplify PCB design

High-Frequency Rectification Advantages in Harsh Industrial Sites

| Clean AC-DC front-end performance for Pakistani plants | SiC high-frequency rectifier bridge | Conventional silicon bridge |

|---|---|---|

| Reverse recovery charge (Qrr) | Near-zero | High (induces EMI/heat) |

| Efficiency at partial load | High (reduced switching loss) | Moderate/low |

| THD contribution | Lower with HF operation and PFC | Higher, more input distortion |

| Thermal behavior at 45°C ambient | Stable, less derating | More derating, higher heatsink needs |

| Size/weight of magnetics | Smaller (higher frequency) | Larger (lower frequency) |

| Maintenance (fans/filters) | Reduced (lower thermal load) | Higher (more heat to evacuate) |

Key Advantages and Proven Benefits

- Lower losses and heat: SiC near-zero Qrr slashes switching losses and diode recovery spikes—cutting heatsink size and HVAC load.

- Compact and modular: High-frequency operation enables smaller chokes/transformers; modules pack more power in less space.

- Cleaner input current: Works seamlessly with PFC stages to achieve PF >0.99 and THD <3%, improving transformer health and meeting Grid Code quality goals.

- High-temperature resilience: Maintains performance at elevated Tj, suitable for hot, dusty industrial electrical rooms.

- Reliability under unstable mains: Reduced stress during sags/swells and better EMI behavior improves system uptime.

Expert quote:

“SiC diodes’ negligible reverse recovery radically improves front-end efficiency and lowers EMI—a key enabler for compact, compliant AC-DC systems in industrial environments.” — Dr. Johann Kolar, ETH Zurich, Power Electronic Systems Laboratory (contextual reference to PES research summaries and conference keynotes)

Real-World Applications and Measurable Success Stories

- Lahore data center UPS rectifier front-end:

- SiC rectifier bridges paired with interleaved PFC achieved 97%+ rectifier efficiency.

- Input THD reduced to <3%, PF ~0.99; UPS room footprint cut ~30%; year-one electricity cost down ~12.6%.

- Faisalabad textile mill auxiliary supplies:

- Replacing silicon bridges with SiC modules in AC-DC supplies allowed higher switching frequency and smaller magnetics.

- Result: 5–6% energy savings and 15% reduction in enclosure temperatures; fewer thermal-related shutdowns.

- Cement plant control power (Punjab):

- SiC bridge modules in 3-phase rectifiers endured high dust and 42°C ambient with minimal derating.

- MTBF improvement estimated at 20% due to lower thermal stress and improved EMI margin.

【Image prompt: detailed technical description】 Side-by-side visualization: left—traditional silicon rectifier bridge with large heatsink and bulky choke; right—SiC high-frequency rectifier with compact magnetics and smaller heatsink; overlay graphs of input current waveform (more sinusoidal) and THD reduction; industrial panel backdrop; 4K, annotated infographic style.

Selection and Maintenance Considerations

- Electrical selection:

- Choose voltage/current ratings with 20–30% margin for line transients and ambient heat.

- Validate surge immunity with MOV/TVS coordination; consider soft-start to limit inrush.

- Thermal management:

- Use high-conductivity TIM and verify clamping pressure; evaluate RθJC under 40–45°C ambient.

- Consider sealed or positive-pressure enclosures in cement/textile environments to reduce dust ingress.

- EMC and harmonics:

- Combine with interleaved boost PFC for PF >0.99 and THD <3%.

- Layout for low loop inductance; place snubbers close to terminals; ensure proper grounding per IEC 61000-6-4.

- Maintenance:

- Periodically inspect terminal torque and connector integrity.

- Monitor NTC trends to pre-empt cooling system degradation.

Industry Success Factors and Customer Testimonials

- Success factors:

- Early harmonic study and transformer loading analysis

- Proper thermal path design and airflow modeling

- EMI pre-compliance testing at full temperature range

- On-site pilots during peak summer and dusty seasons

- Testimonial (Electrical Supervisor, Karachi steel service center):

- “Switching to SiC bridges stabilized our DC buses and lowered cabinet temperatures, cutting fan maintenance by nearly a quarter.”

Future Innovations and Market Trends

- 2025–2027 outlook:

- Higher-current 1200/1700 V SiC bridges for medium-voltage front-ends via multi-pulse or multi-level schemes

- Integrated bridge-PFC power stages with embedded sensing and digital control

- Cost declines from expanded SiC wafer capacity; increased local assembly opportunities in Pakistan

- Enhanced protective coatings and sealed modules optimized for high-particulate environments

Authority perspective:

“The maturation of SiC supply chains and packaging is accelerating industrial adoption, with rectifier and PFC stages among the fastest to benefit.” — IEEE Power Electronics Magazine industry outlook, 2024

Common Questions and Expert Answers

- Will higher dv/dt from high-frequency stages impact upstream mains?

- With proper EMI filtering and interleaved PFC, conducted emissions remain within IEC limits and reduce transformer stress.

- Can SiC bridges handle frequent voltage sags/swells common in local feeders?

- Yes. Their lower recovery stress and robust thermal capability improve tolerance; we add surge protection tailored to site studies.

- What THD and PF can we expect?

- With SiC bridge plus active PFC: THD <3%, PF ≥0.99 for most loads, supporting NTDC Grid Code quality objectives.

- What is the typical ROI in Pakistani plants?

- 18–30 months depending on duty cycle, tariffs, and cooling savings; faster in 24/7 operations like cement and data centers.

Why This Solution Works for Your Operations

High-frequency SiC rectifier bridge modules are the foundation of compact, efficient, and compliant AC-DC front-ends. In Pakistan’s hot, dusty, and grid-variable conditions, they cut losses, shrink enclosures, and improve power quality—translating into lower OPEX, higher uptime, and easier compliance with harmonics and safety standards.

Connect with Specialists for Custom Solutions

Work with Sicarb Tech to design rectifier bridges that match your exact operating profile:

- Over 10 years of SiC manufacturing expertise, backed by the Chinese Academy of Sciences

- Custom product development spanning R-SiC, SSiC, RBSiC, SiSiC materials and advanced module packaging

- Technology transfer and factory establishment services—from feasibility to commissioning—enabling local value addition

- Turnkey delivery: from material processing to finished modules, with application engineering and compliance support

- Proven results across 19+ enterprises; rapid prototyping and pilot deployments in challenging environments

Book a free consultation for a site-specific harmonic and ROI assessment.

- Email: [email protected]

- Phone/WhatsApp: +86 133 6536 0038

Reserve engineering slots now for Q4 2025 pilots and secure priority lead times before peak demand.

Article Metadata

- Last updated: 2025-09-11

- Next scheduled review: 2025-12-15

- Author: Sicarb Tech Application Engineering Team

- Contact: [email protected] | +86 133 6536 0038

- Standards focus: IEC 61000-3-2/3, IEC 62477-1, IEC 62040; aligned with PEC practices and NTDC Grid Code quality criteria

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.