New SiC Developments Impacting Global Industries

Share

New SiC Developments Impacting Global Industries

In the relentless pursuit of higher performance, greater efficiency, and unparalleled durability, industries worldwide are increasingly turning to advanced materials. Among these, silicon carbide (SiC) stands out as a true game-changer, particularly with the advent of custom SiC products. These engineered ceramics are not merely alternatives; they are fundamental enablers of next-generation technologies across a diverse range of sectors, from the intricate world of semiconductor manufacturing to the extreme environments of aerospace and nuclear energy.

This blog post delves into the latest developments in custom silicon carbide, exploring its profound impact on global industries. We will examine the unique advantages of SiC, its myriad applications, critical design considerations, and how to select a reliable supplier for your specific needs. Prepare to uncover why custom SiC components are becoming indispensable for engineers, procurement managers, and technical buyers seeking to push the boundaries of what’s possible.

Main Applications of Custom Silicon Carbide

Custom silicon carbide products offer unparalleled performance in environments where traditional materials fall short. Their unique combination of properties makes them ideal for a vast array of high-stakes industrial applications. Let’s explore some of the key sectors benefiting from SiC advancements:

- Semiconductor Manufacturing: SiC is crucial for high-temperature process equipment, wafer carriers, and electrostatic chucks due to its excellent thermal stability, high purity, and minimal outgassing. This ensures the integrity of delicate semiconductor processes.

- Automotive Industry: From power electronics in electric vehicles (EVs) to braking systems and engine components, SiC’s superior thermal conductivity, high breakdown voltage, and wear resistance are driving efficiency and performance gains.

- Aerospace and Defense: Lightweight yet incredibly strong, custom SiC is used in missile radomes, turbine components, and high-temperature bearings, offering superior thermal shock resistance and rigidity in extreme conditions.

- Power Electronics: SiC-based power devices enable higher switching frequencies, lower power losses, and more compact designs for inverters, converters, and power supplies, leading to more efficient energy management.

- Renewable Energy: Essential for solar inverters and wind turbine power converters, SiC enhances the efficiency and reliability of renewable energy systems, contributing to a greener future.

- Metallurgy and High-Temperature Processing: SiC furnace components, crucibles, and kiln furniture withstand extreme temperatures and corrosive atmospheres, extending equipment lifespan and improving process control.

- Chemical Processing: Its exceptional chemical inertness makes SiC ideal for components exposed to aggressive chemicals, such as pump seals, valve components, and heat exchangers in harsh chemical environments.

- LED Manufacturing: SiC is used for susceptors and process components in the growth of GaN (gallium nitride) crystals, crucial for high-brightness LEDs and other optoelectronic devices.

- Industrial Machinery: Wear-resistant SiC components like nozzles, bearings, and mechanical seals significantly extend the operational life of industrial equipment, reducing maintenance costs and downtime.

- Telecommunications: SiC-based RF devices offer higher power density and efficiency for 5G base stations and other high-frequency communication systems.

- Oil and Gas: Downhole tools and drilling components benefit from SiC’s extreme hardness and corrosion resistance, enabling operations in harsh and abrasive environments.

- Medical Devices: Biocompatible and wear-resistant SiC can be found in surgical instruments and certain implantable devices where high durability and inertness are critical.

- Rail Transportation: SiC power modules enhance the efficiency and reliability of traction systems in electric locomotives and high-speed trains.

- Nuclear Energy: SiC is being explored for fuel cladding and other structural components in advanced nuclear reactors due to its exceptional radiation resistance and high-temperature strength.

Why Choose Custom Silicon Carbide Products?

The decision to opt for custom silicon carbide extends beyond simply selecting a material; it’s about engineering precision solutions for demanding applications. The benefits of customization are manifold:

- Unmatched Thermal Resistance: SiC maintains its strength and integrity at extremely high temperatures, far exceeding the limits of most metals and other ceramics.

- Superior Wear Resistance: Its inherent hardness makes SiC incredibly resistant to abrasion and erosion, significantly extending the lifespan of components in harsh, abrasive environments.

- Exceptional Chemical Inertness: SiC is virtually unaffected by most acids, alkalis, and corrosive gases, making it ideal for chemical processing and other aggressive media applications.

- High Thermal Conductivity: Efficiently dissipates heat, critical for thermal management in power electronics and high-temperature furnace applications.

- Low Thermal Expansion: Minimizes thermal stress and ensures dimensional stability even during rapid temperature fluctuations.

- High Strength and Stiffness: Offers excellent structural integrity under heavy loads and at elevated temperatures.

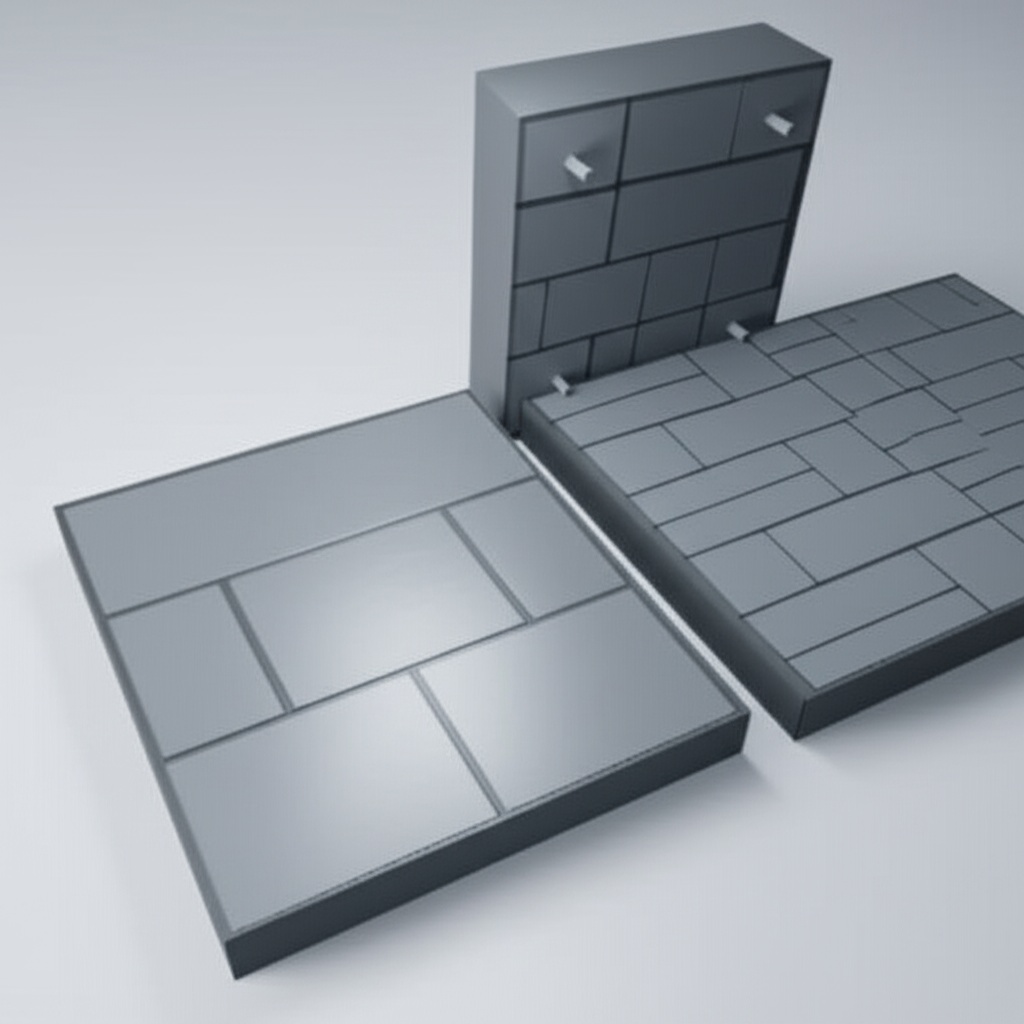

- Tailored Geometries and Features: Customization allows for complex shapes, precise drilling, and intricate internal structures, perfectly matching specific application requirements.

- Optimized Performance: By designing components specifically for their intended use, engineers can maximize efficiency, reduce waste, and improve overall system reliability.

Recommended SiC Grades and Compositions

Silicon carbide is not a single material but rather a family of technical ceramics, each with distinct properties tailored to specific applications. Understanding these grades is crucial for optimal component selection.

| SiC Grade/Type | Key Characteristics | Typical Applications |

|---|---|---|

| Reaction-Bonded Silicon Carbide (RBSC/SiSiC) | Excellent strength, wear resistance, and thermal shock resistance. Good dimensional stability. Can be formed into complex shapes. Contains free silicon. | Kiln furniture, nozzles, mechanical seals, pump components, heat exchangers, semiconductor process equipment. |

| Sintered Alpha Silicon Carbide (Alpha SiC) | High purity, superior corrosion resistance, excellent strength at high temperatures, high hardness. No free silicon. | High-performance mechanical seals, bearings, pump impellers, semiconductor wafer carriers, furnace components, high-purity crucibles. |

| Nitride-Bonded Silicon Carbide (NBSC) | Good thermal shock resistance and strength, but generally lower purity than RBSC or Sintered SiC. Cost-effective for certain applications. | Refractory bricks, kiln furniture, blast furnace liners, general industrial wear parts. |

| Chemically Vapor Deposited (CVD) Silicon Carbide | Extremely high purity, theoretical density, superior strength, and chemical resistance. Forms thin, highly uniform coatings. | Semiconductor susceptors, optical components, high-purity furnace liners, X-ray mirrors. |

Design Considerations for SiC Products

Designing with silicon carbide requires a specialized approach due to its unique material properties, particularly its hardness and brittleness. Careful design can mitigate challenges and maximize performance.

- Minimizing Stress Concentrators: Avoid sharp corners, abrupt changes in cross-section, and deep grooves, as these can create stress points leading to cracking. Radii should be maximized wherever possible.

- Wall Thickness Uniformity: Strive for consistent wall thicknesses to promote uniform cooling during manufacturing and minimize internal stresses.

- Hole and Feature Placement: Design holes and features with sufficient spacing from edges and other features to prevent material weakening. Consider through-holes over blind holes where possible.

- Material Shrinkage: Account for material shrinkage during sintering or reaction bonding processes. Suppliers will provide specific shrinkage rates for their materials.

- Machinability: While SiC is extremely hard, it can be machined with diamond tooling after firing. Design features to be as machinable as possible, minimizing complex internal geometries that are difficult to reach.

- Attachment Methods: Consider how the SiC component will be attached to other parts of an assembly. Mechanical fastening, adhesive bonding, or brazing all have specific design implications.

Tolerance, Surface Finish & Dimensional Accuracy

Achieving precise tolerances and specified surface finishes in silicon carbide components is a testament to advanced manufacturing capabilities. While SiC is a challenging material to machine, significant progress has been made.

- Achievable Tolerances: Precision grinding and lapping allow for very tight tolerances, often within microns, depending on the part size and complexity. For fired, unground parts, tolerances are typically wider.

- Surface Finish Options:

- As-Fired: Typically a rougher surface, suitable for non-critical applications.

- Ground: Achieves a smoother finish and tighter tolerances.

- Lapped/Polished: Provides an extremely smooth, highly reflective surface, critical for sealing surfaces, bearing surfaces, and optical applications.

- Dimensional Accuracy: Highly dependent on the manufacturing process (e.g., slip casting, pressing, 3D printing) and post-processing steps like grinding and lapping. Reputable suppliers can achieve exceptional dimensional accuracy for critical applications.

Post-Processing Needs for Enhanced Performance

While silicon carbide components offer inherent advantages, post-processing steps can further optimize their performance, durability, and functionality for specific applications.

- Precision Grinding: Essential for achieving tight dimensional tolerances, flatness, and specific surface finishes on fired SiC parts.

- Lapping and Polishing: Used to create extremely smooth and flat surfaces, crucial for applications requiring high sealing integrity (e.g., mechanical seals), low friction, or optical clarity.

- Sealing/Impregnation: For porous SiC grades (like some RBSC or NBSC), impregnation with resins or metals can enhance impermeability and strength.

- Coatings: Applying specialized coatings (e.g., ceramic, metallic, or diamond-like carbon) can further enhance properties like corrosion resistance, wear resistance, or conductivity for specific functionalities.

- Joining and Assembly: Techniques such as brazing, diffusion bonding, or adhesive bonding may be used to integrate SiC components into larger assemblies, requiring careful consideration of thermal expansion differences.

Common Challenges and How to Overcome Them in SiC Manufacturing

Despite its remarkable properties, working with silicon carbide presents certain manufacturing and application challenges. Understanding and addressing these is key to successful implementation.

- Brittleness: Like most ceramics, SiC is inherently brittle. This requires careful handling during manufacturing, transport, and installation. Designs should avoid stress concentrators and thin sections that could be prone to chipping or cracking.

- Machining Complexity: The extreme hardness of SiC makes it incredibly difficult and expensive to machine, requiring specialized diamond tooling and advanced grinding techniques. This impacts manufacturing costs and lead times.

- Thermal Shock Sensitivity: While SiC has good thermal shock resistance compared to many ceramics, rapid, extreme temperature changes can still induce stress and potential failure, particularly in less dense grades. Proper design and process control can mitigate this.

- High Sintering Temperatures: Producing fully dense SiC requires extremely high temperatures (over 2000°C), which demands specialized furnaces and precise atmosphere control, contributing to manufacturing costs.

- Cost: Due to raw material purity, complex processing, and specialized machining, custom SiC components can have a higher upfront cost compared to traditional materials. However, their extended lifespan and performance often result in lower total cost of ownership.

Overcoming these challenges relies on expertise in material science, advanced manufacturing processes, and collaborative design efforts between the customer and the SiC supplier.

How to Choose the Right Custom SiC Supplier

Selecting a reliable supplier for custom silicon carbide products is paramount to project success. A capable partner provides not just components, but technical expertise and support.

- Technical Expertise and R&D Capabilities: Look for a supplier with a deep understanding of SiC material science, processing techniques, and a history of successful custom projects. Inquire about their R&D investments and ability to innovate.

- Material Options and Customization: Ensure they offer a wide range of SiC grades (RBSC, Sintered, NBSC, etc.) and the capability to tailor compositions or develop new ones for unique requirements.

- Manufacturing Capabilities: Assess their ability to produce complex geometries, tight tolerances, and various surface finishes. Ask about their precision machining, grinding, and polishing capabilities.

- Quality Control and Certifications: Verify their quality management systems (e.g., ISO 9001) and their commitment to stringent quality control throughout the manufacturing process.

- Industry Experience: A supplier with experience in your specific industry (e.g., semiconductors, aerospace, power electronics) will better understand your application’s nuances and regulatory requirements.

- Lead Time and Production Capacity: Discuss their typical lead times for custom orders and their capacity to meet your production volume needs.

- Customer Support and Collaboration: A good supplier acts as a partner, offering design assistance, material selection guidance, and responsive technical support.

When considering a reliable partner for your silicon carbide needs, it’s worth noting the unique capabilities emerging from the heart of China’s SiC manufacturing. Here is the hub of China’s silicon carbide customizable parts factories. As you are aware, the hub of China’s silicon carbide customizable parts manufacturing is situated in Weifang City of China. Now the region has been home to over 40 silicon carbide production enterprises of various sizes, collectively accounting for more than 80% of the nation’s total silicon carbide output.

We, Sicarb Tech, have been introducing and implementing silicon carbide production technology since 2015, assisting the local enterprises in achieving large-scale production and technological advancements in product processes. We have been a witness to the emergence and ongoing development of the local silicon carbide industry.

Based on the platform of the national technology transfer center of the Chinese Academy of Sciences, Sicarb Tech is an entrepreneurial park that collaborates closely with the National Technology Transfer Center of the Chinese Academy of Sciences. It serves as a national-level innovation and entrepreneurship service platform, integrating innovation, entrepreneurship, technology transfer, venture capital, incubation, acceleration, and scientific and technological services.

Cost Drivers and Lead Time Considerations for SiC

Understanding the factors influencing the cost and lead time of custom silicon carbide components is vital for effective project planning and procurement.

| Cost Driver | Impact | Mitigation/Consideration |

|---|---|---|

| Material Grade & Purity | Higher purity and specialized SiC grades (e.g., Sintered Alpha SiC, CVD SiC) are more expensive due to raw material costs and complex processing. | Match material grade to application needs; avoid over-specifying. |

| Part Complexity & Geometry | Intricate designs, thin walls, small holes, or highly precise features increase machining difficulty and waste, driving up costs. | Simplify designs where possible; collaborate with supplier on manufacturability. |

| Tolerances & Surface Finish | Tighter tolerances and smoother finishes (lapping/polishing) require more intensive, time-consuming post-processing. | Specify only the necessary tolerances and finishes for critical areas. |

| Volume of Production | Lower volumes typically incur higher per-unit costs due to fixed setup costs. Larger volumes benefit from economies of scale. | Consider minimum order quantities; evaluate total project needs over time. |

| Post-Processing Requirements | Extensive grinding, lapping, coating, or specialized sealing adds to the overall cost and lead time. | Only include necessary post-processing steps. |

Lead Time Factors:

- Material Availability: Specialized SiC raw materials may have longer lead times from suppliers.

- Manufacturing Process: The specific SiC forming process (e.g., slip casting, pressing) and subsequent firing cycles are time-consuming.

- Machining & Post-Processing: The hardness of SiC means machining takes longer, and complex geometries or ultra-fine finishes add significant time.

- Supplier Backlog: A busy supplier may have longer queues for new orders.

- Tooling Development: For highly custom parts, initial tooling development can add several weeks or months to the first production run.

Frequently Asked Questions (FAQ) about Custom Silicon Carbide

Here are some common questions we receive regarding custom silicon carbide products:

Q1: Is silicon carbide brittle, and how does that affect design?

A1: Yes, like other advanced ceramics, silicon carbide is brittle. This means it has very high compressive strength but relatively lower tensile strength compared to metals. In design, this necessitates avoiding sharp corners, abrupt changes in cross-section, and designing for compressive loads wherever possible. Proper handling and mounting are also crucial to prevent chipping or cracking.

Q2: Can silicon carbide be repaired if damaged?

A2: Repairing damaged silicon carbide components is generally challenging due to its extreme hardness and inertness. Minor chips or surface imperfections might be addressed through grinding or polishing, but significant structural damage usually requires replacement. Preventative design and careful handling are the best strategies.

Q3: What are the typical operating temperatures for SiC components?

A3: Silicon carbide boasts exceptional high-temperature stability. Depending on the specific grade (e.g., Sintered SiC, Reaction-Bonded SiC), it can typically operate continuously in air up to 1600°C (2912°F) or even higher in inert or vacuum atmospheres. Its strength is largely retained even at these elevated temperatures, making it ideal for high-temperature processing environments.

Q4: How does the cost of SiC compare to other high-performance materials?

A4: The initial unit cost of custom silicon carbide components is often higher than traditional metals or less specialized ceramics. However, its superior performance in terms of wear resistance, corrosion resistance, and high-temperature stability often translates to a significantly lower total cost of ownership over the component’s lifespan due to reduced downtime, fewer replacements, and improved process efficiency. The investment in SiC often pays for itself through enhanced operational longevity and performance.

Conclusion: The Future is Forged in Custom Silicon Carbide

The burgeoning advancements in custom silicon carbide represent a pivotal shift in material science, offering unparalleled solutions for the world’s most demanding industrial environments. From revolutionizing semiconductor manufacturing and enabling the next generation of electric vehicles to enhancing the efficiency of power electronics and ensuring the integrity of critical aerospace components, SiC is more than just a material – it’s an engineering imperative.

By leveraging custom silicon carbide, industries can unlock new levels of performance, extend component lifespans, reduce maintenance, and operate efficiently in extreme conditions that would degrade conventional materials. The journey from design to final product requires deep technical expertise, precision manufacturing, and a collaborative partnership with a specialized SiC supplier.

As the global demand for higher efficiency, increased reliability, and extreme performance continues to grow, custom silicon carbide will undoubtedly remain at the forefront of material innovation, driving progress across every sector it touches. Embrace the power of SiC customization to build the future, one robust, high-performance component at a time.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.