Mastering Material Excellence: A Deep Dive into SiC Pressure Forming Equipment

Share

In the realm of high-performance industrial applications, the demand for materials that can withstand extreme conditions is ever-increasing. Silicon Carbide (SiC) has emerged as a frontrunner, offering exceptional thermal resistance, wear resistance, and chemical inertness. However, harnessing the full potential of SiC often requires specialized manufacturing processes. SiC pressure forming equipment plays a pivotal role in this, enabling the creation of dense, high-strength, and complex-shaped SiC components. This blog post will delve into the intricacies of SiC pressure forming equipment, exploring its technologies, applications, and the critical considerations for businesses looking to leverage this advanced manufacturing capability. For engineers, procurement managers, and technical buyers in sectors like semiconductors, high-temperature processing, aerospace, energy, and industrial manufacturing, understanding this equipment is key to unlocking new levels of performance and innovation.

The ability to produce custom SiC components tailored to specific operational demands is a significant advantage. Standard off-the-shelf parts may not always meet the stringent requirements of cutting-edge applications. This is where the synergy between advanced materials like SiC and sophisticated processing equipment, such as pressure forming systems, becomes crucial. By precisely controlling the forming parameters, manufacturers can achieve superior material properties and intricate geometries, pushing the boundaries of what’s possible in demanding industrial environments. Companies specializing in technical ceramics and industrial SiC procurement are increasingly recognizing the value of pressure-formed SiC for its enhanced reliability and longevity.

Core Technologies in SiC Pressure Forming

The production of high-quality Silicon Carbide components often relies on advanced pressure-assisted sintering techniques. These methods are essential for achieving high densification and superior mechanical properties in the final SiC parts. The choice of technology depends on the desired characteristics of the component, production volume, and cost considerations. Each technique utilizes controlled pressure and temperature to consolidate SiC powders into a dense, robust ceramic.

Three primary pressure forming technologies dominate the landscape for SiC manufacturing:

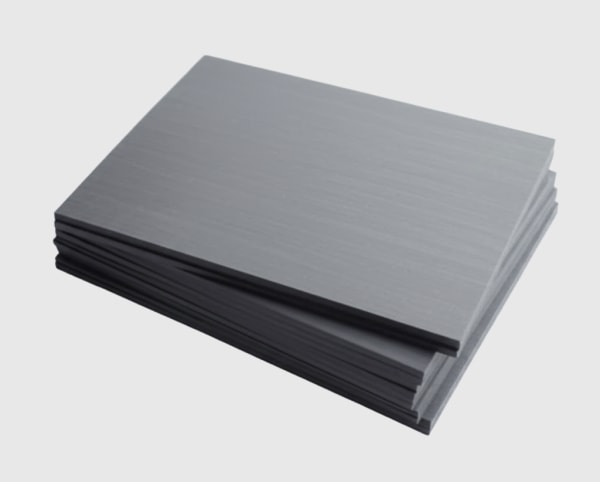

- Hot Pressing (HP): This technique involves the simultaneous application of high temperature and uniaxial pressure to a SiC powder compact within a die. The pressure is typically applied in one direction. Hot pressing is effective in producing relatively simple shapes with high density and fine microstructures. It is widely used for manufacturing sputtering targets, armor plates, and certain types of wear parts. The advantage lies in achieving excellent material properties, though the shapes are somewhat limited by the die design.

- Process: SiC powder is placed in a graphite die.

- Pressure: Uniaxial, typically 10-50 MPa.

- Temperature: 1800°C−2200°C.

- Atmosphere: Inert gas (e.g., Argon) or vacuum.

- Outcome: High-density SiC parts, often requiring subsequent machining for complex geometries.

- Hot Isostatic Pressing (HIP): HIP is a more advanced technique where SiC components (either pre-sintered or encapsulated powders) are subjected to high temperature and isostatic gas pressure from all directions. This uniform pressure application leads to highly dense and homogenous materials, eliminating internal porosity and enhancing mechanical properties like strength and toughness. HIP is ideal for complex shapes and critical applications where material integrity is paramount.

- Process: Pre-formed SiC parts or encapsulated powders are loaded into a high-pressure vessel.

- Pressure: Isostatic (uniform from all directions), typically 100-200 MPa, applied via an inert gas like Argon.

- Temperature: 1700°C−2000°C.

- Outcome: Near-net-shape or net-shape parts with exceptional density (often >99% theoretical density) and improved mechanical properties. This method is crucial for high-density SiC parts for demanding applications.

- Gas Pressure Sintering (GPS): GPS is a variation where SiC powder compacts are sintered under high gas pressure (typically Nitrogen or Argon) at elevated temperatures. While similar to HIP, GPS often involves lower pressures but can still achieve high densities. It’s particularly useful for nitrogen-containing SiC grades or when specific atmospheric reactions are desired during sintering. This method can be more cost-effective than HIP for certain applications while still yielding high-performance advanced ceramics.

The selection of the appropriate pressure forming technology is a critical decision that influences not only the final properties of the SiC component but also the overall manufacturing efficiency and cost. Sicarb Tech, with its deep understanding of SiC production technology, leverages these advanced forming techniques to produce superior custom SiC components and can guide clients in selecting the optimal process for their specific needs. Our expertise, rooted in the heart of China’s SiC manufacturing hub in Weifang City, ensures access to cutting-edge equipment and process know-how.

Why Invest in Advanced SiC Pressure Forming Equipment?

Investing in advanced SiC pressure forming equipment is not merely an upgrade of manufacturing capabilities; it’s a strategic move towards producing superior quality custom SiC products that can meet the increasingly stringent demands of modern industries. The benefits of utilizing such equipment translate directly into enhanced product performance, greater design freedom, and improved operational efficiency.

The primary advantages of using advanced SiC pressure forming equipment include:

- Achieving Near-Net-Shape Components: Pressure-assisted techniques, especially Hot Isostatic Pressing (HIP), allow for the production of components that are very close to their final desired dimensions. This significantly reduces the need for extensive and costly post-sintering machining, which is particularly challenging and expensive for hard materials like SiC. Reduced machining translates to lower material waste and faster production cycles.

- Superior Density and Reduced Porosity: High pressure applied during the forming process helps to eliminate voids and porosity within the SiC material. This results in components with significantly higher density, often approaching the theoretical maximum. High density is directly linked to improved mechanical strength, hardness, and wear resistance. For applications in harsh environments, such as industrial furnaces or semiconductor processing equipment, low porosity also means better resistance to chemical attack and permeation.

- Enhanced Mechanical Strength and Reliability: The combination of high temperature and pressure promotes better bonding between SiC grains, leading to a finer, more uniform microstructure. This refined microstructure results in superior mechanical properties, including higher flexural strength, fracture toughness, and hardness. Components manufactured using pressure forming are therefore more reliable and durable under mechanical stress and thermal shock.

- Improved Material Homogeneity: Isostatic pressure, as applied in HIP, ensures uniform densification throughout the component, regardless of its complexity. This leads to consistent material properties across the entire part, eliminating weak spots and ensuring predictable performance. This is critical for applications where even minor inconsistencies can lead to failure, such as in aerospace components or precision machinery parts.

- Capability to Produce Complex Geometries: While traditional ceramic forming methods might struggle with intricate designs, advanced pressure forming techniques, coupled with appropriate tooling and encapsulation methods (for HIP), enable the production of SiC parts with complex three-dimensional shapes. This opens up new design possibilities for engineers looking to optimize component performance through geometry.

- Consistency and Reproducibility: Modern SiC pressure forming equipment comes with sophisticated control systems that allow for precise regulation of temperature, pressure, and cycle times. This ensures high consistency and reproducibility from batch to batch, a critical factor for OEMs and wholesale buyers requiring reliable supply chains for technical ceramics.

The table below summarizes the key benefits linked to different pressure forming techniques:

| Feature | Hot Pressing (HP) | Hot Isostatic Pressing (HIP) | Gas Pressure Sintering (GPS) |

|---|---|---|---|

| Density Achieved | High (typically >98%) | Very High (often >99.5%) | High (typically >98%) |

| Shape Complexity | Low to Moderate | High (with encapsulation) | Moderate to High |

| Machining Required | Often significant | Minimal (near-net-shape) | Moderate |

| Mechanical Properties | Good to Excellent | Excellent to Superior | Good to Excellent |

| Material Homogeneity | Good (potential for minor anisotropy) | Excellent (isotropic) | Very Good |

| Typical Applications | Armor, wear parts, sputtering targets | Aerospace, medical, critical industrial components | Bearings, seals, nozzles |

| Suitability for Custom SiC | Good for simpler custom shapes needing high density | Ideal for complex, high-performance custom SiC parts | Versatile for various custom applications |

Investing in or partnering with a provider that utilizes advanced SiC pressure forming equipment, like Sicarb Tech, ensures that you are leveraging the best available technology for your critical SiC components. Our commitment to SiC production technology and our location in Weifang, a major hub for silicon carbide, means we are at the forefront of these advancements, offering our clients unparalleled quality and performance in their custom silicon carbide products.

Key Components and System Design of SiC Pressure Forming Equipment

The efficacy and precision of SiC pressure forming equipment hinge on the sophisticated design and integration of its key components. Each element plays a crucial role in achieving the desired temperature, pressure, and atmospheric conditions necessary for producing high-quality, dense technical ceramics. Understanding these components is essential for operators, procurement managers, and engineers involved in advanced ceramics processing.

Modern SiC pressure forming systems, whether Hot Presses, Hot Isostatic Presses (HIP units), or Gas Pressure Sintering (GPS) furnaces, share common foundational elements, albeit with variations specific to the technology:

- High-Pressure Vessel/Chamber: This is the core of the equipment, designed to safely contain the extreme pressures (ranging from tens to hundreds of MPa) and high temperatures involved in the process.

- Material: Typically constructed from high-strength steel alloys. For HIP units, designs often involve layered cylinders or wire-winding to ensure integrity under cyclic loading.

- Design Features: Equipped with secure sealing mechanisms, safety relief valves, and often cooling jackets to manage external temperatures. The internal volume dictates the maximum size and batch quantity of SiC parts.

- Importance: The vessel’s integrity is paramount for safety and operational reliability.

- Heating System: Responsible for elevating the SiC powder or pre-forms to the required sintering temperatures, often exceeding 2000°C.

- Types:

- Graphite Resistance Heaters: Common due to their ability to reach high temperatures and their chemical compatibility with SiC processing environments.

- Induction Heaters: Offer rapid heating rates and good temperature uniformity, particularly for Hot Pressing where the die itself can be inductively heated.

- Molybdenum or Tungsten Resistance Heaters: Used in specific atmospheres or when graphite is not suitable.

- Control: Precise temperature control is achieved through thermocouples or pyrometers linked to sophisticated PID controllers. Uniform temperature distribution within the hot zone is critical for consistent sintering.

- Types:

- Pressure Generation and Control System: This system delivers and maintains the required pressure throughout the forming cycle.

- Hot Pressing (Uniaxial): Typically uses hydraulic rams to apply force to the die punches. Pressure is controlled via hydraulic pumps and valves.

- HIP and GPS (Isostatic/Gas Pressure): Involves gas compressors (often multi-stage) to pump inert gas (like Argon or Nitrogen for GPS) into the pressure vessel. Precision pressure transducers and control valves maintain the set pressure.

- Accuracy: Accurate pressure application and control are vital for achieving target density and avoiding component damage.

- Atmosphere Control System: Essential for preventing oxidation of SiC and the heating elements at high temperatures, and in some cases, to provide a reactive atmosphere (e.g., Nitrogen in some GPS processes).

- Components: Vacuum pumps (to evacuate air before introducing process gas), gas supply lines, flow meters, and purity monitors.

- Gases Used: Typically high-purity Argon or Nitrogen. Vacuum conditions are often established before backfilling with the process gas.

- Impact: The purity of the atmosphere directly affects the quality and properties of the sintered SiC.

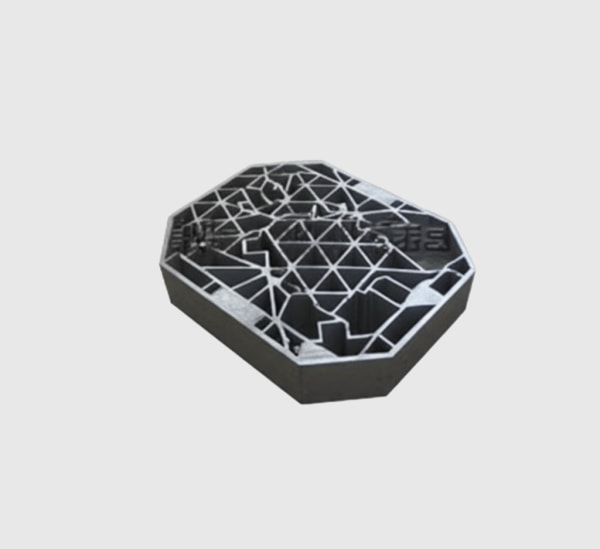

- Tooling and Fixturing (especially for Hot Pressing and HIP):

- Hot Pressing: Graphite dies and punches are commonly used due to their high-temperature strength and machinability. Die design is critical for part shape and densification.

- HIP: Components may be placed on refractory metal or ceramic trays. For powder consolidation, powders are often encapsulated in a gas-impermeable container (e.g., glass or metal) that deforms under pressure to shape the part.

- Material Choice: Tooling materials must withstand the process conditions without reacting with the SiC.

- Control and Data Acquisition System: The brain of the equipment, typically a PLC (Programmable Logic Controller) or computer-based system.

- Functions: Manages all process parameters (temperature, pressure, ramp rates, hold times, gas flow), executes pre-programmed cycles, monitors safety interlocks, and logs process data.

- User Interface: Provides operators with real-time information and control over the process.

- Benefits: Ensures reproducibility, provides valuable data for quality control and process optimization, and enhances operational safety.

- Safety Systems: Given the extreme conditions, robust safety interlocks and emergency shutdown systems are integral.

- Features: Over-pressure relief, over-temperature cut-offs, door interlocks, and emergency stop buttons.

- Compliance: Equipment must comply with relevant industrial safety standards.

Industrial Applications Benefiting from Pressure-Formed SiC Components

The exceptional properties of Silicon Carbide (SiC) components produced via advanced SiC pressure forming equipment make them indispensable in a wide array of demanding industrial applications. The ability to achieve high density, superior mechanical strength, excellent thermal conductivity, and chemical resistance opens doors for custom SiC products to thrive where conventional materials fail. Industries that heavily rely on technical ceramics are increasingly turning to pressure-formed SiC to enhance performance, efficiency, and reliability.

Here’s a look at key sectors and their applications of pressure-formed SiC:

- Semiconductor Manufacturing: This industry demands ultra-high purity, dimensional stability, and resistance to corrosive plasma environments.

- Applications: Wafer chucks (electrostatic or vacuum), focus rings, showerheads, dummy wafers, CMP (Chemical Mechanical Planarization) retainer rings, and components for etching and deposition chambers.

- Why Pressure-Formed SiC?: Provides the necessary stiffness, thermal stability (managing heat from plasma), wear resistance against abrasive slurries (in CMP), and purity to prevent contamination of silicon wafers. High-density SiC parts ensure longevity and consistent performance in these critical processes.

- Aerospace and Defense: Components in these sectors face extreme temperatures, high mechanical stresses, and require lightweight solutions.

- Applications: Rocket nozzles, missile components, leading edges for hypersonic vehicles, turbine engine components (blades, vanes, shrouds), reconnaissance mirrors, and lightweight armor.

- Why Pressure-Formed SiC?: Offers excellent high-temperature strength, thermal shock resistance, low density compared to superalloys, and superior hardness for armor applications. The ability to form complex shapes via HIP is particularly advantageous for aerospace components.

- High-Temperature Furnaces and Heat Treatment: Industrial furnaces require materials that can withstand continuous operation at extreme temperatures and resist thermal cycling.

- Applications: Kiln furniture (beams, rollers, setters, plates), radiant tubes, thermocouple protection tubes, crucibles, and burner nozzles.

- Why Pressure-Formed SiC?: Exceptional thermal conductivity, high-temperature strength, resistance to oxidation and creep, ensuring longer life and energy efficiency in industrial furnaces. Reaction-bonded SiC (RBSiC) and Sintered SiC (SSiC), often produced using pressure-assisted methods, are common choices.

- Energy Sector (including Power Generation and Renewables): Components in this sector often encounter high temperatures, corrosive environments, and wear.

- Applications: Heat exchanger tubes, components for concentrated solar power (CSP) systems, parts for nuclear applications (requiring radiation resistance), and wear-resistant components in fuel cells or biomass converters.

- Why Pressure-Formed SiC?: Provides excellent thermal shock resistance, high thermal conductivity for efficient heat transfer, and corrosion resistance, leading to improved system efficiency and durability.

- Industrial Manufacturing and Wear Components: Many industrial processes involve abrasive materials, high temperatures, or corrosive chemicals, leading to rapid wear of conventional parts.

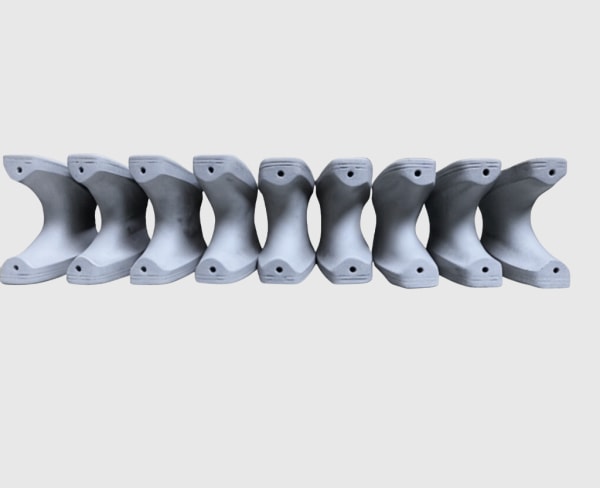

- Applications: Mechanical seals, bearings, pump components (shafts, impellers), nozzles for sandblasting or slurry transport, cyclone liners, and cutting tools.

- Why Pressure-Formed SiC?: Outstanding hardness, wear resistance, and corrosion resistance significantly extend the service life of components, reducing downtime and maintenance costs. This is a key area for industrial SiC procurement.

- Optics and Metrology: Applications requiring high stiffness, thermal stability, and the ability to be polished to a very smooth surface.

- Applications: Lightweight optical mirrors for telescopes and satellites, laser components, and precision metrology stages.

- Why Pressure-Formed SiC?: High specific stiffness (stiffness-to-weight ratio), low thermal expansion, and excellent polishability.

The table below illustrates some specific SiC grades and their suitability for applications typically manufactured using pressure forming techniques:

| SiC Grade | Key Properties | Typical Pressure Forming Method(s) | Common Industrial Applications |

|---|---|---|---|

| Sintered Silicon Carbide (SSiC) | High purity, excellent corrosion & wear resistance | HIP, GPS, HP | Semiconductor parts, chemical pump components, mechanical seals, nozzles, bearings |

| Reaction-Bonded SiC (RBSiC/SiSiC) | Good mechanical strength, complex shapes possible, cost-effective | Often pressureless sintered, but HIP can enhance | Kiln furniture, wear liners, large structural components, heat exchangers |

| Hot-Pressed SiC (HPSiC) | Very high density, excellent hardness & strength | HP | Armor, cutting tools, specialized wear parts, sputtering targets |

| Nitride-Bonded SiC (NBSiC) | Good thermal shock resistance, high hot strength | Often pressureless, but GPS can be used | Furnace components, refractories, components for molten metal handling |

The versatility of SiC pressure forming equipment allows manufacturers like Sicarb Tech to cater to these diverse industries. Our location in Weifang, the hub of China’s silicon carbide customizable parts factories, positions us perfectly to collaborate with businesses seeking high-performance custom SiC components. We leverage our extensive experience and the technological backing of the Chinese Academy of Sciences to deliver solutions that meet the unique challenges of each application.

Operational Excellence: Optimizing Your SiC Pressure Forming Process

Achieving consistently high-quality custom SiC products from SiC pressure forming equipment requires more than just sophisticated machinery; it demands operational excellence. This involves meticulous control over process parameters, careful material selection, thoughtful design, and diligent maintenance. For businesses involved in advanced ceramics processing or those looking to enhance their SiC production technology, optimizing these aspects is key to maximizing yield, performance, and cost-effectiveness.

Key factors for optimizing the SiC pressure forming process include:

- Precise Control of Process Parameters:

- Temperature: Accurate temperature control, including ramp rates (how quickly temperature is increased/decreased) and hold times at peak temperature, is crucial. Non-uniform heating or incorrect temperatures can lead to incomplete sintering, grain growth, or thermal stress. Modern equipment offers programmable cycles for precise control.

- Pressure: The applied pressure, its rate of application, and duration must be carefully controlled. Insufficient pressure results in lower density, while excessive pressure can damage tooling or the component. For HIP and GPS, the pressurization and depressurization rates are also critical.

- Atmosphere: Maintaining the integrity and purity of the inert atmosphere (e.g., Argon, Nitrogen) is vital to prevent oxidation and unwanted reactions. Gas flow rates and vacuum levels (before backfilling) must be monitored.

- Cycle Time: Optimizing the overall cycle time without compromising product quality is essential for throughput and energy efficiency. This involves balancing heating, soaking, and cooling phases.

- Raw Material Quality and Preparation:

- Powder Characteristics: The starting SiC powder’s purity, particle size distribution, and morphology significantly impact the sintering process and final properties. High-quality, consistent powders are essential.

- Binder Addition (if applicable): For some processes, organic binders are mixed with the SiC powder to aid in green body formation before pressure sintering. The type and amount of binder, and its complete burnout before densification, are critical.

- Powder Compaction (for Hot Pressing/GPS): Uniform packing of the powder in the die or mold ensures even densification.

- Mold and Die Design (especially for Hot Pressing):

- Material: Graphite is common, but its grade and design must withstand high temperatures and pressures without excessive wear or reaction.

- Tolerances: Precision machining of dies is necessary for producing near-net-shape parts and ensuring proper pressure transmission.

- Thermal Expansion: The design must account for the thermal expansion of both the SiC material and the die material to prevent cracking or stress.

- Encapsulation (for HIP of powders or porous parts):

- Material: Glass, refractory metals, or other deformable, impermeable materials are used to create a “can” around the SiC powder or pre-form.

- Sealing: The encapsulation must be perfectly sealed to prevent gas penetration, which would counteract the applied isostatic pressure.

- Interaction: The encapsulant should not react detrimentally with the SiC.

- Loading and Unloading Procedures:

- Careful handling of green bodies and sintered parts is necessary to prevent damage.

- Proper positioning of parts within the furnace ensures uniform exposure to heat and pressure.

- Preventative Maintenance of Equipment:

- Regular Inspections: Heating elements, thermocouples, pressure sensors, seals, and vacuum systems need regular checks and calibration.

- Component Replacement: Proactive replacement of wear parts (e.g., die liners, heating elements, seals) prevents unexpected downtime and compromised batches.

- Cleaning: Keeping the furnace chamber and components clean prevents contamination.

- Record Keeping: Maintaining logs of maintenance activities and equipment performance helps in identifying trends and potential issues.

- Operator Training and Expertise:

- Well-trained operators who understand the SiC material, the equipment’s functioning, and the critical process parameters are invaluable.

- Expertise in troubleshooting and process adjustment can significantly improve output quality. CAS new materials (SicSino), with its deep roots in the Weifang SiC industry and support from the Chinese Academy of SciencesNational Technology Transfer Center, emphasizes the importance of skilled personnel in achieving optimal results.

Key Engineering Tips for Process Optimization:

- Start with high-quality SiC powder: The adage “garbage in, garbage out” holds true. Consistent powder with controlled particle size is fundamental.

- Profile your furnace: Understand the temperature uniformity within your specific SiC pressure forming equipment to optimize part placement.

- Implement Statistical Process Control (SPC): Monitor key process parameters and part characteristics to identify and control variability.

- Conduct pilot runs for new designs: Before full-scale production of custom SiC components, test runs help refine parameters and identify potential issues.

- Invest in good metrology: Accurate measurement of part dimensions, density, and other properties is crucial for quality control and process improvement.

By focusing on these operational aspects, manufacturers can ensure their SiC pressure forming equipment operates at peak efficiency, producing high-quality technical ceramics that meet the exacting standards of industries such as semiconductors, aerospace, and high-temperature processing. Companies like Sicarb Tech not only apply these principles in their own production but also offer this expertise as part of their technology transfer services for clients wishing to establish their own SiC production facilities.

Selecting Your Partner for SiC Pressure Forming Equipment and Expertise

Choosing the right supplier for SiC pressure forming equipment or for sourcing custom SiC components manufactured using these advanced techniques is a critical decision that significantly impacts your project’s success, product quality, and overall cost-effectiveness. The ideal partner offers more than just machinery or parts; they provide comprehensive technical support, material expertise, customization capabilities, and potentially even turnkey solutions for establishing your own production.

When evaluating potential suppliers, especially for industrial SiC procurement or technical ceramics manufacturing equipment, consider the following crucial factors:

- Technical Expertise and Experience:

- Depth of Knowledge: Does the supplier possess a profound understanding of SiC materials science, various pressure forming technologies (HP, HIP, GPS), and their nuances?

- Application Experience: Have they successfully provided solutions for your specific industry or similar demanding applications? Ask for case studies or references.

- Problem-Solving Capabilities: Can they assist in troubleshooting processing issues or developing custom solutions for unique challenges?

- Equipment Quality and Capabilities:

- Range of Equipment: Do they offer equipment that matches your required scale, pressure and temperature ranges, and shape complexity needs?

- Component Quality: Are the critical components of their equipment (pressure vessels, heating systems, controls) sourced from reputable manufacturers and built to high standards?

- Process Control: How sophisticated are the control systems? Do they offer precise parameter regulation, data logging, and recipe management?

- Compliance and Safety: Does the equipment meet relevant industry safety standards and certifications?

- Customization and Flexibility:

- Tailored Solutions: Can the supplier customize equipment to meet specific process requirements or integrate it into existing production lines?

- Material Versatility: Can their equipment handle different grades of SiC and potentially other advanced ceramics?

- Prototyping and R&D Support: Do they offer support for developing new SiC components or optimizing existing designs?

- After-Sales Support and Service:

- Installation and Commissioning: What level of support is provided during setup and initial operation?

- Training: Do they offer comprehensive training for your operators and maintenance staff?

- Spare Parts Availability: Are spare parts readily available to minimize downtime?

- Technical Support: Is responsive and knowledgeable technical support accessible when issues arise?

- Technology Transfer and Turnkey Solutions:

- For businesses looking to establish or upgrade their own SiC production technology, does the supplier offer comprehensive technology transfer? This might include factory design, equipment procurement and installation, process know-how, and trial production assistance.

- Sicarb Tech, for instance, excels in this area. Based in Weifang City, the hub of China’s silicon carbide customizable parts factories, and backed by the robust scientific capabilities of the Chinese Academy of Sciences , we offer more than just components. We are committed to assisting clients in establishing their own specialized SiC production plants through comprehensive turnkey projects. This includes providing the technology transfer for professional silicon carbide production, factory design, procurement of specialized equipment, installation, commissioning, and trial production. Our approach ensures a more effective investment, reliable technology transformation, and a guaranteed input-output ratio.

- Company Reputation and Reliability:

- Track Record: What is their history in the industry? How long have they been specializing in SiC or advanced ceramics?

- Certifications: Do they hold relevant quality certifications (e.g., ISO 9001)?

- Location and Infrastructure: A supplier with a strong R&D background and manufacturing infrastructure, like CAS new materials (SicSino) through its association with the Chinese Academy of Sciences (Weifang) Innovation Park, offers greater reliability. We have been instrumental in the technological advancement of the local SiC industry since 2015.

- Cost-Effectiveness and Lead Time:

- While initial cost is a factor, consider the total cost of ownership, including maintenance, reliability, and the quality of the final SiC product.

- Evaluate lead times for equipment delivery or custom part production.

- Sicarb Tech prides itself on offering higher-quality, cost-competitive customized silicon carbide components from China, thanks to our integrated process from materials to products and our support for local enterprises.

The table below offers a quick checklist for evaluating suppliers:

| Evaluation Criterion | Key Questions to Ask | Why It’s Important for SiC Pressure Forming |

|---|---|---|

| Technical Expertise | What is your experience with [specific SiC grade/application]? Can you share material data? | Ensures correct process parameters and material selection for optimal custom SiC product performance. |

| Equipment Specifications | What are the max temperature/pressure ratings? What is the hot zone size? What type of control system is used? | Determines if the equipment can meet your production needs for technical ceramics. |

| Customization | Can you modify the equipment for [specific requirement]? Do you offer design support for SiC components? | Essential if standard offerings don’t fit, or if you need specialized SiC production technology. |

| Support & Service | What does your warranty cover? What is the typical response time for service? Do you offer remote diagnostics? | Minimizes downtime and ensures long-term operational efficiency of SiC equipment. |

| Technology Transfer | Do you offer turnkey plant solutions? What does your technology transfer package include? | Crucial for companies wanting to build in-house advanced ceramics processing capabilities. |

| Supplier Reliability | Can you provide customer testimonials or references? What are your quality assurance procedures? | Builds confidence in consistent supply and product quality for industrial SiC procurement. |

Choosing Sicarb Tech means partnering with an organization deeply embedded in the SiC industry, possessing a domestic top-tier professional team, and leveraging the formidable scientific and technological capabilities of the Chinese Academy of Sciences. We don’t just sell equipment or parts; we provide comprehensive solutions and foster technological advancement, making us a reliable partner for your SiC pressure forming equipment and expertise needs. Our support has benefited over 10 local enterprises, enhancing their technological capabilities and production scale.

Common Challenges in SiC Pressure Forming and Mitigation Strategies

While SiC pressure forming equipment enables the production of high-performance custom SiC components, the process is not without its challenges. Silicon Carbide itself is an inherently hard and brittle material, and the extreme temperatures and pressures involved in forming introduce complexities. Understanding these potential issues and implementing effective mitigation strategies are crucial for achieving consistent quality and efficient production in advanced ceramics processing.

Key challenges and their solutions include:

- Achieving Full and Uniform Densification:

- Challenge: Incomplete densification leads to porosity, which compromises mechanical strength, thermal conductivity, and chemical resistance. Non-uniform density can create weak spots.

- Mitigation:

- Optimize Powder: Use SiC powders with appropriate particle size distribution and morphology for better packing and sinterability.

- Process Parameters: Precisely control temperature, pressure, and hold times. Ensure uniform temperature distribution within the hot zone.

- Pressure Application: For Hot Pressing, ensure uniform pressure transmission through proper die design. For HIP/GPS, ensure effective gas penetration and pressure.

- Sintering Aids: Judicious use of sintering aids can promote liquid phase sintering (in some SiC types like LPS-SiC) or solid-state diffusion, but their type and amount must be carefully controlled to avoid degrading properties.

- Controlling Grain Growth:

- Challenge: Excessive grain growth during high-temperature sintering can reduce mechanical strength and toughness (Hall-Petch relationship).

- Mitigation:

- Lower Sintering Temperature/Time: If possible, reduce peak temperature or hold time, provided densification is not compromised.

- Grain Growth Inhibitors: Small additions of specific dopants (e.g., boron and carbon for SSiC) can pin grain boundaries and limit growth.

- Rapid Sintering Techniques: Techniques like Spark Plasma Sintering (SPS), a type of field-assisted sintering technique (FAST) which also uses pressure, can achieve densification at lower temperatures and shorter times, limiting grain growth, though this is a distinct technology from conventional HP/HIP/GPS.

- Managing Thermal Stresses and Cracking:

- Challenge: SiC’s high elastic modulus and relatively low fracture toughness make it susceptible to cracking from thermal stresses generated during rapid heating or cooling, especially in complex shapes or large components.

- Mitigation:

- Controlled Heating/Cooling Rates: Employ slower, programmed ramp rates, particularly through critical temperature ranges where phase transformations or significant thermal expansion/contraction occur.

- Component Design: Avoid sharp corners, abrupt changes in thickness, and features that act as stress concentrators.

- Furnace Uniformity: Ensure uniform temperature within the SiC pressure forming equipment to minimize thermal gradients.

- Support Fixtures: Use appropriate kiln furniture or supports that allow for some movement during shrinkage or expansion.

- Tooling Wear and Interaction (especially in Hot Pressing):

- Challenge: Graphite dies and punches used in Hot Pressing can wear or react with SiC at very high temperatures and pressures, leading to dimensional inaccuracies or contamination.

- Mitigation:

- High-Quality Graphite: Use dense, high-strength graphite grades.

- Protective Coatings: Apply coatings (e.g., boron nitride) to die surfaces to act as a barrier and lubricant.

- Process Optimization: Avoid unnecessarily high pressures or temperatures.

- Die Design: Design dies for longevity and ease of replacement of wear surfaces.

- Complexity of Encapsulation (for HIP of Powders):

- Challenge: Effectively encapsulating SiC powder to achieve a gas-tight seal that can deform appropriately under HIP conditions is complex and critical for achieving net-shape parts. Defects in encapsulation lead to failed consolidation.

- Mitigation:

- Material Selection: Choose appropriate can materials (glass, metal) based on HIP temperature and compatibility with SiC.

- Robust Sealing Techniques: Employ reliable welding or sealing methods for the cans.

- Pre-compaction: Pre-compacting powder within the can can improve final density and shape control.

- Modeling: Use Finite Element Analysis (FEA) to predict deformation of the can and powder compact during HIP.

- Atmosphere Control and Purity:

- Challenge: Contamination from the furnace atmosphere (e.g., oxygen, moisture) or impurities in the process gas can react with SiC, forming undesirable phases (like SiO2) that affect properties and surface finish.

- Mitigation:

- High-Purity Gases: Use high-purity Argon or Nitrogen.

- Vacuum Integrity: Ensure a good initial vacuum to remove air and moisture before backfilling with process gas.

- Furnace Materials: Use non-reactive internal furnace components.

- Regular Maintenance: Check for leaks in gas lines and vessel seals.

- Cost and Throughput:

- Challenge: Pressure forming processes can be energy-intensive and have longer cycle times compared to some other ceramic forming methods, impacting cost and throughput.

- Mitigation:

- Process Optimization: Fine-tune cycle parameters for the shortest effective time.

- Batch Size: Maximize batch size within the equipment’s capacity.

- Energy-Efficient Equipment: Modern designs often incorporate better insulation and heating element technology.

- Near-Net-Shape Forming: Reducing post-sintering machining saves significant time and cost. Sicarb Tech focuses on delivering higher-quality, cost-competitive custom silicon carbide components by optimizing these very aspects, leveraging our integrated process from materials to products.

Addressing these challenges requires a combination of material science knowledge, engineering expertise, and meticulous process control. Companies like Sicarb Tech, with their strong R&D background supported by the Chinese Academy of Sciences and practical experience in Weifang’s SiC industrial cluster, are well-equipped to navigate these complexities. We provide not only custom SiC parts that have overcome these hurdles but also offer technology transfer to empower clients with the knowledge to manage these challenges in their own SiC production technology.

Frequently Asked Questions (FAQ) about SiC Pressure Forming Equipment

Engineers, procurement managers, and technical buyers often have specific questions when considering SiC pressure forming equipment or components made using these processes. Here are some common queries with concise, practical answers:

1. What are the main differences between Hot Pressing (HP), Hot Isostatic Pressing (HIP), and Gas Pressure Sintering (GPS) for SiC?

These are all pressure-assisted sintering techniques used to achieve high-density Silicon Carbide, but they differ in how pressure and temperature are applied:

- Hot Pressing (HP): Applies uniaxial (one-direction) pressure to SiC powder in a die at high temperatures. Best for simpler shapes, good for high hardness and density, but can result in some anisotropy (direction-dependent properties).

- Hot Isostatic Pressing (HIP): Applies isostatic (uniform, all-direction) gas pressure to pre-formed parts or encapsulated powders at high temperatures. Excellent for complex shapes, achieves very high and uniform density, superior mechanical properties, and isotropic behavior. Often used for critical components.

- Gas Pressure Sintering (GPS): Similar to HIP but typically uses gas pressure (often nitrogen for SiC) during the sintering cycle, sometimes at slightly lower pressures than HIP. Can achieve high densities and is effective for certain SiC grades or when a specific gas atmosphere is beneficial during densification.

The choice depends on the desired final properties, shape complexity, and cost targets of the custom SiC products.

2. What kind of dimensional tolerances and surface finishes can be achieved with SiC parts made by pressure forming equipment?

- Dimensional Tolerances: Pressure forming techniques, especially HIP, can produce near-net-shape SiC components. As-sintered tolerances can range from ±0.5% to ±1% of the dimension. However, for tighter tolerances, post-sintering machining (grinding, lapping, polishing) is almost always required. With precision machining, tolerances as tight as a few microns (μm) can be achieved.

- Surface Finish: The as-sintered surface finish of pressure-formed SiC parts typically ranges from Ra=0.8μm to Ra=3.2μm, depending on the powder characteristics, tooling, and specific process. For applications requiring very smooth surfaces (e.g., seals, mirrors, semiconductor components), post-machining processes like lapping and polishing can achieve surface finishes down to Ra<0.02μm or even optical quality. Sicarb Tech has extensive experience in both forming and finishing technical ceramics to meet precise specifications.

3. Can SiC pressure forming equipment be used for materials other than Silicon Carbide?

Yes, the fundamental principles of applying heat and pressure to consolidate powders are applicable to a wide range of advanced materials. SiC pressure forming equipment, particularly Hot Presses and Hot Isostatic Presses, can often be adapted (with considerations for temperature limits, atmosphere compatibility, and tooling materials) for processing:

- Other Technical Ceramics: Alumina (Al2O3), Zirconia (ZrO2), Silicon Nitride (Si3N4), Boron Carbide (B4C), and various composite ceramics.

- Powder Metallurgy (P/M) Metals: Refractory metals (e.g., Tungsten, Molybdenum), superalloys, and metal matrix composites.

- Cermets: Ceramic-metal composites.

The specific equipment design (e.g., maximum temperature, pressure, available atmospheres) will dictate its suitability for other materials. If you are considering establishing a versatile advanced ceramics processing facility, this is an important factor. Sicarb Tech can provide guidance on equipment capabilities and even assist with technology transfer for a range of materials processing, backed by the broad expertise of the Chinese Academy of Sciences.

4. What are the primary cost drivers for SiC components manufactured using pressure forming, and what are typical lead times?

Several factors influence the cost and lead time of custom SiC components produced by pressure forming:

- Cost Drivers:

- Raw Material Grade & Purity: Higher purity SiC powders are more expensive.

- Complexity of Design: Intricate shapes require more complex tooling (for HP) or encapsulation and potentially more machining.

- Size of the Component: Larger parts consume more material and may require larger, more specialized equipment.

- Density and Performance Requirements: Achieving very high densities or specific mechanical properties might necessitate longer cycles or more advanced techniques (e.g., HIP vs. HP).

- Production Volume: Smaller batches or one-off custom parts generally have higher per-unit costs than large production runs due to setup and tooling amortization.

- Machining & Finishing: The extent of post-sintering machining significantly impacts cost, as SiC is very hard to machine.

- Quality Control & Testing: Stringent inspection and testing requirements add to the cost.

- Lead Times:

- Prototyping/Custom Parts: Typically range from 4 to 12 weeks, depending on complexity, material availability, and current workload.

- Production Volumes: Once a design is established, production lead times can be shorter and more predictable, often in the range of 6 to 10 weeks, but this is highly dependent on volume and scheduling.

- Equipment Purchase: Lead time for new SiC pressure forming equipment can range from 6 months to over a year, depending on customization and manufacturer backlog.

Sicarb Tech, situated in Weifang City – a major hub for silicon carbide production – leverages efficient supply chains and advanced manufacturing processes to offer competitive pricing and manageable lead times for industrial SiC procurement. Our integrated approach, from material sourcing to final product, allows us to optimize for both cost and delivery.

Conclusion: Embracing Precision and Performance with SiC Pressure Forming

The journey through the world of SiC pressure forming equipment reveals a landscape of sophisticated technology dedicated to unlocking the exceptional potential of Silicon Carbide. From the foundational principles of Hot Pressing, Hot Isostatic Pressing, and Gas Pressure Sintering to the intricacies of equipment design and operational excellence, it’s clear that pressure forming is indispensable for creating custom SiC components that meet the highest standards of performance and reliability.

Industries ranging from semiconductor manufacturing and aerospace to energy and high-temperature processing depend on the superior density, strength, and complex geometries achievable through these advanced techniques. While challenges exist, from managing thermal stresses to controlling grain growth, they are surmountable with deep material science knowledge, robust engineering, and meticulous process control – hallmarks of experienced providers.

When selecting a partner for your SiC needs, whether for acquiring technical ceramics manufacturing equipment or sourcing high-quality industrial SiC components, expertise, customization capabilities, and comprehensive support are paramount. Sicarb Tech stands as a testament to this ethos. Rooted in Weifang City, the heart of China’s SiC industry, and powered by the innovative spirit and technological prowess of the Chinese Academy of Sciences, we offer more than just products; we offer partnerships. Our commitment extends from providing cost-effective, high-quality customized SiC parts to empowering global clients through technology transfer and turnkey solutions for establishing their own state-of-the-art SiC production technology.

By embracing the precision and performance offered by SiC pressure forming, businesses can drive innovation, enhance product durability, and gain a competitive edge in the demanding industrial environments of today and tomorrow. Partner with Sicarb Tech to navigate the complexities of advanced ceramics and transform your material challenges into performance breakthroughs.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.