Mastering Precision: A Deep Dive into SiC Cutting Machines for High-Performance Industrial Applications

Share

Silicon Carbide (SiC) has emerged as a critical material in numerous high-performance industrial applications due to its exceptional properties, including high hardness, excellent thermal conductivity, and superior resistance to wear and corrosion. However, these very properties make SiC a challenging material to machine. Specialized SiC cutting machines are therefore essential for shaping SiC components with the precision and efficiency required by industries such as semiconductors, aerospace, and advanced manufacturing. This blog post delves into the world of SiC cutting machines, exploring their applications, advantages, types, design considerations, and the crucial factors in selecting the right equipment and supplier. For businesses looking to leverage the benefits of custom SiC components, understanding the intricacies of SiC cutting technology is paramount.

The Crucial Role of SiC Cutting Machines in Modern Industries

SiC cutting machines are not just tools; they are enablers of innovation across a spectrum of demanding sectors. The ability to precisely cut and shape Silicon Carbide allows engineers and designers to harness its unique characteristics for components that must perform under extreme conditions. In the semiconductor industry, for example, SiC wafers are fundamental to producing next-generation power electronics. These devices, known for their efficiency and ability to operate at high voltages and temperatures, require meticulous cutting and dicing, a task where precision SiC dicing machines and SiC wafer cutting machines excel.

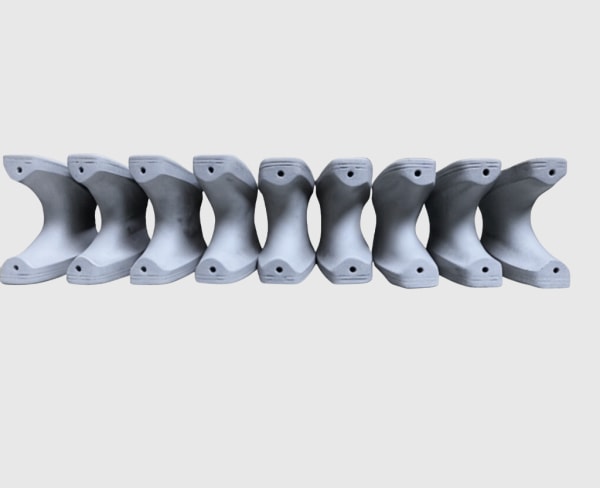

Beyond semiconductors, the aerospace sector benefits from SiC components in applications like high-temperature engine parts and lightweight structural elements. The energy industry, particularly in high-temperature furnace construction and nuclear applications, relies on SiC’s thermal stability and resistance to harsh environments. Furthermore, industrial manufacturing utilizes SiC for wear-resistant parts, seals, bearings, and nozzles. The common thread across these diverse applications is the need for accurately machined SiC parts, making advanced industrial SiC cutting equipment indispensable. As the demand for high-performance materials grows, so does the importance of sophisticated technical ceramics cutting solutions.

For procurement managers and technical buyers, sourcing high-quality, custom-cut SiC components is critical. This often leads them to seek partners with deep expertise in both SiC materials and advanced machining processes. Companies like Sicarb Tech, situated in Weifang City, the hub of China’s silicon carbide customizable parts manufacturing, are pivotal in this ecosystem. SicSino, backed by the robust scientific and technological capabilities of the Chinese Academy of Sciences , has been instrumental in advancing SiC production technology since 2015. Their expertise in custom SiC component machining ensures that industries can access the precise components they need.

Key Industrial Applications Demanding Precision SiC Cutting

The unique properties of Silicon Carbide make it suitable for a wide array of demanding applications. The ability to accurately cut and shape this advanced ceramic is crucial for realizing its full potential. Below is a table highlighting key industries and their specific applications for custom-cut SiC components:

| Industry Sector | Specific Applications of Custom Cut SiC Components | SiC Properties Leveraged | Common SiC Cutting Machine Types Used |

|---|---|---|---|

| Semiconductors | Wafer substrates, dummy wafers, LED manufacturing components, power device packaging | High thermal conductivity, electrical insulation, purity | Diamond wire saws, Laser cutting, Dicing saws |

| Aerospace & Defense | Turbine components, rocket nozzles, armor, mirrors for optical systems | High strength-to-weight ratio, thermal shock resistance | Abrasive waterjet, Diamond grinding, Laser |

| High-Temperature Furnaces | Heating elements, kiln furniture (beams, rollers, plates), thermocouple protection tubes | High-temperature stability, thermal shock resistance, strength | Diamond saws, Grinding machines |

| Energy (incl. Nuclear) | Heat exchangers, fuel cladding components, components for fusion reactors | High thermal conductivity, radiation resistance, corrosion resistance | Diamond wire saws, EDM (for conductive SiC) |

| Industrial Manufacturing | Mechanical seals, bearings, pump components, nozzles, wear-resistant linings, cutting tool inserts | High hardness, wear resistance, chemical inertness | Grinding, Lapping, Abrasive waterjet |

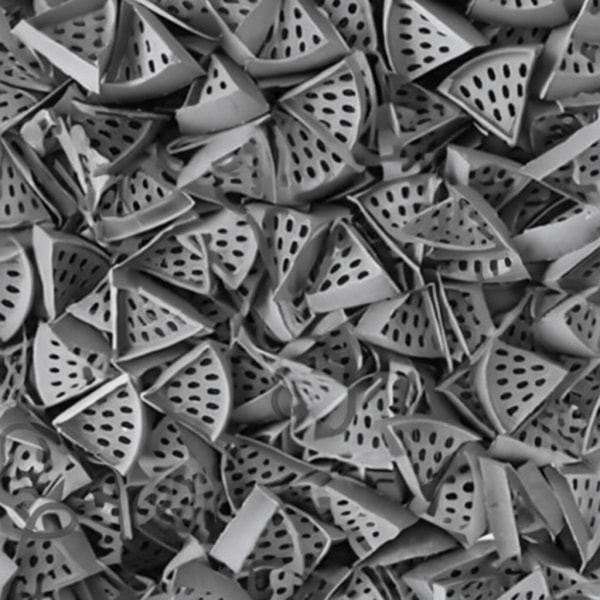

| Automotive | Brake discs, diesel particulate filters, components for electric vehicle power modules | Wear resistance, high-temperature stability, thermal conductivity | Diamond grinding, Laser cutting |

| Chemical Processing | Pump shafts and sleeves, valve components, reaction vessel linings | Chemical inertness, corrosion resistance, wear resistance | Diamond machining, Abrasive waterjet |

As seen in the table, the applications are diverse and demanding, underscoring the need for specialized SiC cutting machines and processes. The choice of cutting method often depends on the complexity of the part, the required tolerances, and the specific grade of SiC being processed. For instance, SiC wafer cutting machines using diamond wire technology are preferred for their ability to produce thin, precise wafers with minimal kerf loss, which is vital for maximizing yield in semiconductor manufacturing. Similarly, laser cutting silicon carbide offers a non-contact method ideal for intricate patterns and can minimize mechanical stress on the material.

The demand for wholesale SiC components and OEM SiC parts is steadily increasing as more industries recognize the advantages of this advanced material. This trend highlights the importance of reliable suppliers capable of delivering high-quality, custom-cut SiC products.

Unlocking Performance: Advantages of Utilizing Advanced SiC Cutting Technology

The decision to invest in or specify components cut using advanced SiC cutting technology stems from a range of benefits crucial for high-performance applications. While SiC itself offers remarkable material properties, it is the precision of the cutting and machining process that truly unlocks its potential for complex and demanding end-uses.

Key Advantages:

- Enhanced Precision and Tight Tolerances: Modern SiC cutting machines, such as laser cutters, diamond wire saws, and precision grinders, can achieve exceptionally tight tolerances and intricate geometries. This is critical for applications like semiconductor wafers, where dimensional accuracy directly impacts device performance, and for aerospace components, where fit and function are paramount.

- Improved Material Integrity: Advanced cutting techniques, particularly non-contact methods like laser cutting or low-stress methods like diamond wire sawing, minimize the risk of micro-cracks, chipping, and sub-surface damage. This preserves the inherent strength and reliability of the SiC material, leading to more durable and dependable components.

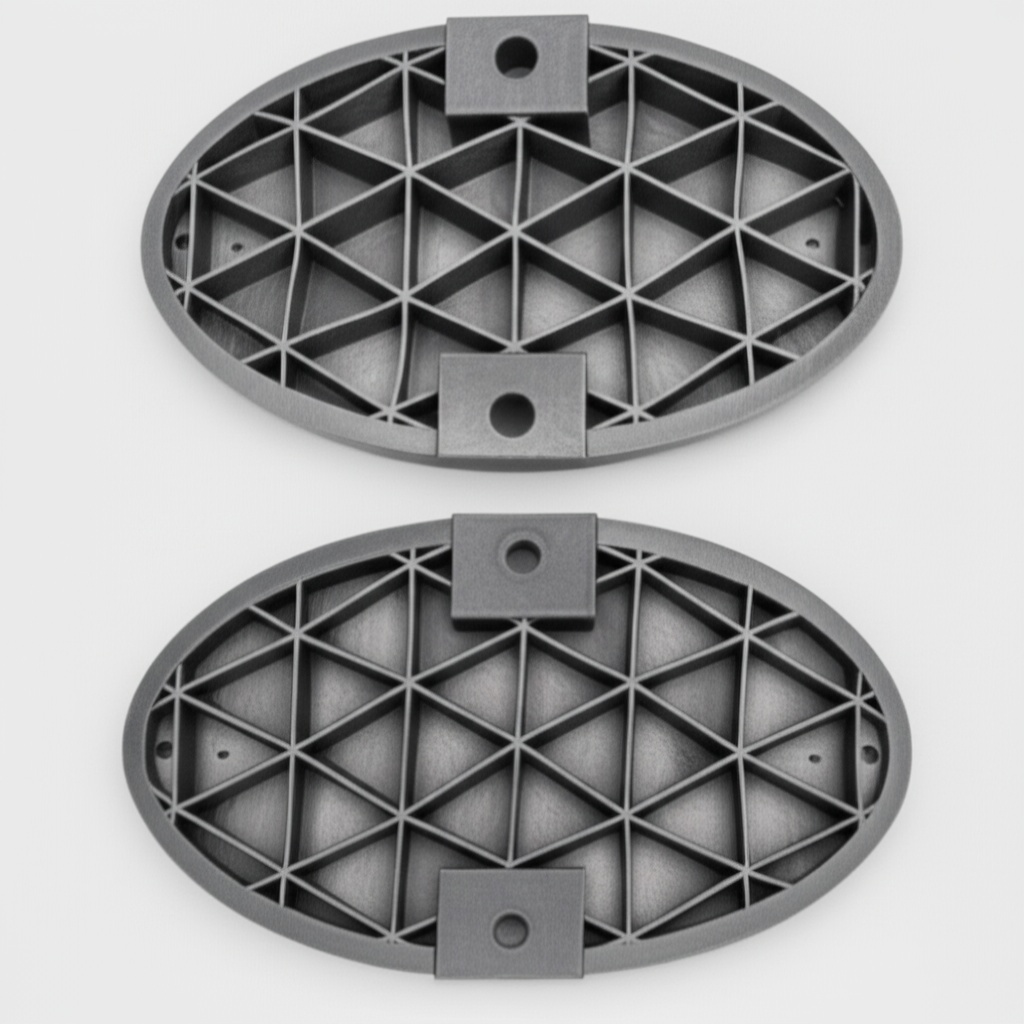

- Complex Geometries and Customization: Custom SiC component machining allows for the creation of complex shapes and features that would be difficult or impossible to achieve with traditional ceramic forming methods alone. This design flexibility enables engineers to optimize parts for specific functional requirements, such as improved fluid dynamics in nozzles or enhanced heat dissipation in thermal management systems.

- Higher Yield and Reduced Material Waste: Precision cutting methods, especially those with minimal kerf loss (like fine diamond wires or focused laser beams), maximize the number of usable parts from a single SiC boule or blank. This is particularly important for expensive, high-purity SiC grades, contributing to cost-effectiveness in wholesale SiC components manufacturing.

- Faster Prototyping and Production: Automated SiC cutting machines can significantly reduce machining times compared to manual or less specialized methods. This accelerates prototyping cycles and enables faster ramp-up to full-scale production, which is crucial for meeting time-to-market pressures in dynamic industries.

- Consistent Quality and Repeatability: CNC (Computer Numerical Control) integration in modern SiC cutting equipment ensures high levels of repeatability from part to part and batch to batch. This consistency is vital for OEMs and technical procurement professionals who rely on uniform component quality for their assembly lines and final products.

- Suitability for Various SiC Grades: Advanced cutting technologies can be adapted to different types of SiC, including sintered silicon carbide (SSC), reaction-bonded silicon carbide (RBSC or SiSiC), and others. Each grade may have slightly different machining characteristics, and versatile cutting solutions can accommodate these variations.

Sicarb Tech leverages these advanced cutting technologies to support local enterprises in Weifang, China – the heart of the nation’s SiC industry. By providing access to state-of-the-art material, process, and design technologies, SicSino helps ensure that businesses can procure high-quality, cost-competitive customized silicon carbide components. Their integrated process, from materials to finished products, underscores the value of advanced cutting in achieving superior end-results.

Exploring the Spectrum: Types of SiC Cutting Machines and Their Mechanisms

Processing Silicon Carbide effectively requires specialized machinery due to the material’s extreme hardness and brittleness. Various types of SiC cutting machines have been developed, each employing different mechanisms to achieve material removal and shaping. The choice of machine depends on factors such as the required precision, production volume, complexity of the cut, and the specific type of SiC material.

Here’s an overview of common SiC cutting machine types and their operational principles:

- Diamond Wire Saws:

- Mechanism: These machines use a rapidly moving steel wire, often less than 100μm in diameter, impregnated or coated with fine diamond abrasives. The wire, typically in a slurry of cutting fluid, slices through the SiC material through a gentle abrasive action. Multi-wire versions allow for simultaneous cutting of multiple wafers from an ingot.

- Advantages: Produces very thin cuts with minimal kerf loss, excellent for wafering and slicing large SiC boules. Achieves good surface finish and minimizes sub-surface damage.

- Applications: SiC wafer cutting machines for semiconductor and LED substrates, slicing of optical components.

- Keywords: Diamond wire cutting SiC, SiC wafer slicing, precision SiC sawing.

- Diamond Blade Saws (Dicing Saws):

- Mechanism: Employ a circular blade with diamond abrasive particles embedded in its cutting edge. The blade rotates at high speed to grind or cut through the SiC. Coolant is essential to manage heat and remove debris.

- Advantages: Faster cutting speeds for straight cuts compared to wire saws for certain applications, suitable for dicing wafers into individual chips or cutting smaller components.

- Applications: Dicing SiC wafers, cutting SiC tubes, rods, and plates into smaller sections.

- Keywords: SiC dicing machines, diamond blade SiC cutting, industrial SiC sawing.

- Laser Cutting Machines:

- Mechanism: Utilize a high-intensity focused laser beam to melt, vaporize, or thermally fracture the SiC material along the desired cutting path. Different laser types (e.g., Nd:YAG, fiber, ultrashort pulse lasers) can be used, each offering specific advantages in terms of cut quality and heat-affected zone (HAZ). Stealth dicing (internal modification followed by cleaving) is an advanced laser technique for wafers.

- Advantages: Non-contact process, minimizing mechanical stress and tool wear. Capable of intricate patterns and high precision. Can be very fast for certain applications. Ultrashort pulse lasers can significantly reduce HAZ.

- Applications: Cutting complex shapes, scribing, drilling micro-holes, SiC wafer dicing (especially stealth dicing).

- Keywords: Laser cutting silicon carbide, SiC laser ablation, precision laser machining SiC.

- Abrasive Waterjet (AWJ) Cutting Machines:

- Mechanism: A high-velocity jet of water (pressurized up to 60,000 psi or higher) is mixed with fine abrasive particles (e.g., garnet). This powerful stream erodes the SiC material.

- Advantages: No heat-affected zone, can cut very thick SiC sections, versatile for various shapes and materials, minimal dust.

- Applications: Cutting thick SiC plates, complex 2D shapes, rough machining before finishing operations.

- Keywords: Abrasive jet machining SiC, waterjet SiC cutting, cold cutting SiC.

- Grinding Machines (Surface, Cylindrical, CNC):

- Mechanism: Employ rotating abrasive wheels (typically diamond wheels for SiC) to remove material and achieve precise dimensions and surface finishes. CNC grinders allow for complex profiles and automated operations.

- Advantages: Capable of achieving very high dimensional accuracy and excellent surface finishes. Essential for final shaping and finishing of SiC components.

- Applications: Precision grinding of SiC seals, bearings, shafts, optical components, and achieving tight tolerances on previously cut parts.

- Keywords: SiC grinding services, diamond grinding SiC, precision SiC machining.

- Electrical Discharge Machining (EDM) – for conductive SiC grades:

- Mechanism: Uses electrical sparks (discharges) between an electrode and the conductive SiC workpiece submerged in a dielectric fluid. The sparks erode the material.

- Advantages: Can machine complex shapes and cavities in conductive SiC grades that are difficult to achieve with other methods. No direct contact, so no mechanical cutting forces.

- Applications: Machining intricate details in reaction-bonded SiC (RBSC/SiSiC) components which contain free silicon and are thus electrically conductive.

- Keywords: EDM SiC machining, conductive SiC cutting.

The selection of the appropriate SiC cutting machine is critical for OEMs and technical procurement professionals. Understanding the capabilities and limitations of each technology ensures that components meet specifications for performance and cost. Partnering with a knowledgeable supplier like SicSino, who has access to a wide array of technologies and expertise in material-process interactions, can significantly streamline the procurement of custom SiC products.

Navigating the Blueprint: Critical Design and Operational Considerations for SiC Cutting

Successfully cutting Silicon Carbide requires more than just selecting the right machine; it involves careful consideration of various design and operational factors. These elements are crucial for ensuring manufacturability, achieving desired component performance, and optimizing costs. Engineers and procurement managers should be aware of these aspects when specifying custom SiC components or evaluating a supplier’s capabilities.

Design Considerations for SiC Parts:

- Manufacturability:

- Geometric Complexity: While advanced SiC cutting machines can produce intricate shapes, overly complex designs can significantly increase machining time and cost. Design for Manufacturability (DFM) principles should be applied, simplifying geometries where possible without compromising function. Avoid sharp internal corners, as these are stress concentrators and difficult to machine; incorporate radii instead.

- Wall Thickness and Aspect Ratios: SiC is brittle. Thin walls or features with high aspect ratios (length to thickness) are prone to chipping or fracture during cutting and handling. Minimum achievable wall thickness depends on the SiC grade and cutting method. Consult with your SiC supplier, like SicSino, for guidance on practical limits.

- Feature Tolerances: Specify tolerances that are genuinely required for the application. Unnecessarily tight tolerances drastically increase machining costs and may require multiple processing steps (e.g., rough cutting followed by precision grinding).

- Material Grade Selection: Different SiC grades (e.g., SSiC, SiSiC, NBSC) have varying machinability due to differences in density, porosity, and secondary phases. The chosen grade will influence the optimal cutting parameters and achievable features.

- Stress Points and Brittleness Management:

- Identify and mitigate potential stress concentration points in the design.

- Gradual transitions in thickness and generous fillets can help distribute stress.

- Consider the direction of cutting and potential induced stresses during the machining process.

Operational Considerations for SiC Cutting:

- Cutting Parameters:

- Feed Rate, Speed, Depth of Cut: These must be carefully optimized for the specific SiC grade, cutting tool (e.g., diamond grit size, laser power), and machine type. Aggressive parameters can lead to excessive tool wear, material damage (chipping, cracking), or poor surface finish.

- Coolant/Lubricant Application: Essential for most mechanical cutting processes (diamond sawing, grinding) to reduce heat, flush away debris, and prolong tool life. The type and delivery method of coolant are critical. Laser cutting may use assist gases.

- Tool Wear Management: Diamond tools wear down, and laser optics can degrade. Regular monitoring and replacement schedules are necessary to maintain cut quality and precision. Advanced systems may incorporate in-situ tool wear monitoring.

- Workpiece Clamping and Fixturing:

- Secure and vibration-free clamping is crucial for accurate cutting and to prevent damage to the brittle SiC workpiece. Fixtures must be designed to support the component adequately without inducing stress. Vacuum chucks or specialized adhesives are sometimes used for thin wafers.

- Environmental Controls:

- Temperature stability in the machining environment can affect precision.

- Proper dust and slurry management is necessary for operator safety and machine longevity, especially when dry cutting or grinding SiC, which produces fine, abrasive particulate.

- Process Monitoring and Quality Control:

- In-process monitoring (e.g., acoustic emission sensing, force monitoring) can help detect issues like tool wear or incipient cracking.

- Post-cutting inspection (dimensional checks, surface roughness measurement, visual inspection for defects) is vital to ensure components meet specifications.

Working with an experienced supplier like Sicarb Tech offers significant advantages. Their deep understanding of SiC material science, coupled with expertise in various SiC cutting technologies, allows them to provide valuable input on design optimization and ensure that operational parameters are tailored for high-quality, cost-effective production of technical ceramics components. SicSino’s commitment to assisting clients from design through to delivery helps overcome the challenges inherent in SiC machining, making them a reliable partner for wholesale buyers and OEMs. Their access to the extensive capabilities within Weifang City’s SiC manufacturing cluster further enhances their ability to meet diverse customization needs.

Achieving Perfection: Tolerances, Surface Finish, and Dimensional Accuracy in SiC Cutting

For engineers and procurement professionals in high-tech industries, the achievable tolerances, surface finish, and overall dimensional accuracy of custom silicon carbide products are paramount. These factors directly influence the component’s performance, lifespan, and integration into larger assemblies. The choice of SiC cutting machine and subsequent finishing processes plays a pivotal role in meeting these stringent requirements.

Understanding Tolerances:

Tolerance refers to the permissible limit or limits of variation in a physical dimension of a part. For SiC components, typical achievable tolerances depend heavily on:

- The cutting method employed:

- Diamond Wire Sawing: Can achieve good dimensional control, especially for wafer thickness ($ \pm 5 \mu m$ to $ \pm 25 \mu m$ is common, depending on wafer diameter and process).

- Laser Cutting: Precision varies with laser type and setup. Ultrashort pulse lasers can achieve tolerances in the range of $ \pm 5 \mu m$ to $ \pm 20 \mu m$ for intricate features.

- Diamond Grinding: This is often the most precise method for final dimensions, capable of achieving tolerances as tight as $ \pm 1 \mu m$ to $ \pm 5 \mu m$ for critical features.

- Abrasive Waterjet: Generally offers looser tolerances (e.g., $ \pm 0.1 mm$ or wider) and is often used for near-net shaping before final grinding.

- The SiC material grade: Density, grain size, and presence of secondary phases can affect machining stability and the ability to hold tight tolerances.

- The size and complexity of the component: Larger parts or those with very complex geometries may present greater challenges in maintaining uniform tolerances across all features.

Surface Finish (Ra):

Surface finish, often quantified by the arithmetic average roughness (Ra), is critical for applications involving sealing surfaces, bearings, optical interfaces, or where material strength is paramount (as surface flaws can be crack initiation sites).

- As-Cut Surfaces:

- Diamond wire sawing typically yields Ra values from 0.2μm to 1μm.

- Laser cutting can range widely, from Ra<0.1μm with advanced stealth dicing to several microns for ablative cutting, often with a noticeable heat-affected zone.

- Abrasive Waterjet cutting tends to produce rougher surfaces, often Ra>5μm.

- Finished Surfaces:

- Grinding: Can achieve Ra values from 0.1μm down to 0.02μm (fine grinding).

- Lapping and Polishing: These are secondary finishing processes used to achieve exceptionally smooth surfaces, often with Ra<0.01μm (<10nm), essential for optical and some semiconductor applications.

The following table provides a general comparison of achievable tolerances and surface finishes for different SiC processing methods:

| Machining Process | Typical Achievable Tolerance Range | Typical Achievable Surface Finish (Ra) | Notes |

|---|---|---|---|

| Diamond Wire Sawing | $ \pm 5 \mu m$ to $ \pm 50 \mu m$ | 0.2μm to 1μm | Good for slicing, minimal sub-surface damage. |

| Diamond Blade Dicing | $ \pm 10 \mu m$ to $ \pm 50 \mu m$ | 0.5μm to 2μm | Faster for straight cuts, can cause more chipping than wire sawing. |

| Laser Cutting (Ablative) | $ \pm 20 \mu m$ to $ \pm 100 \mu m$ | 1μm to 5μm | Non-contact, complex shapes, potential HAZ. |

| Laser Cutting (Stealth) | $ \pm 5 \mu m$ to $ \pm 20 \mu m$ | <0.1μm (on cleaved face) | Excellent for wafers, clean edges, minimal debris. |

| Abrasive Waterjet | $ \pm 0.1 mm$ to $ \pm 0.5 mm$ | >5μm | No HAZ, good for thick sections, rougher finish. |

| Precision Grinding | $ \pm 1 \mu m$ to $ \pm 25 \mu m$ | 0.02μm to 0.4μm | High accuracy, excellent finish, often a secondary operation. |

| Lapping/Polishing | Sub-micron improvement | <0.01μm to 0.1μm | Produces mirror-like finishes, essential for optics/some semiconductor uses. |

Dimensional Accuracy:

This refers to the conformity of the actual machined dimensions to the specified nominal dimensions. It encompasses both tolerance and the systematic correctness of the machining process. Achieving high dimensional accuracy requires:

- Calibrated and well-maintained SiC cutting machines.

- Precise tooling and fixturing.

- Careful control of cutting parameters.

- Robust metrology and quality control procedures, including CMM (Coordinate Measuring Machine) checks for complex parts.

Sicarb Tech, with its foundation in the Chinese Academy of Sciences National Technology Transfer Center, deeply understands the interplay between material properties, cutting processes, and achievable precision. They assist enterprises in Weifang in adopting technologies that deliver high-quality customized silicon carbide components meeting stringent dimensional and surface finish specifications. Their integrated approach, encompassing material, process, design, measurement, and evaluation technologies, ensures that OEMs and technical buyers receive parts that perform reliably in demanding applications. For those needing SiC components for industrial applications where precision is non-negotiable, partnering with a supplier with proven capabilities in achieving tight tolerances and fine finishes is crucial.

Beyond the Cut: Post-Processing Needs for SiC Components

The journey of a Silicon Carbide component doesn’t always end once it leaves the SiC cutting machine. Depending on the application’s demands for dimensional accuracy, surface quality, or specific functional properties, various post-processing steps may be necessary. These secondary operations are crucial for enhancing performance, durability, and overall value of custom SiC products.

Common Post-Processing Techniques for SiC Components:

- Grinding:

- Purpose: To achieve very tight dimensional tolerances, improve surface finish, and remove any micro-cracks or sub-surface damage induced during initial cutting (e.g., after diamond sawing or abrasive waterjet cutting).

- Methods: Surface grinding, cylindrical grinding, centerless grinding, and CNC profile grinding using diamond abrasive wheels.

- Relevance: Essential for most precision applications like bearings, seals, shafts, and optical components.

- Lapping:

- Purpose: To produce extremely flat surfaces and improve surface finish beyond what grinding can typically achieve. It involves abrading the SiC surface against a flat plate (lap) with a fine abrasive slurry.

- Methods: Single-sided or double-sided lapping using diamond slurries of decreasing grit size.

- Relevance: Critical for mechanical seals, valve seats, semiconductor wafer chucks, and substrates requiring high flatness.

- Polishing:

- Purpose: To achieve a mirror-like, ultra-smooth surface finish with minimal defects (Ra often in the nanometer range). This reduces friction, improves wear resistance, and is vital for optical applications.

- Methods: Mechanical polishing with fine diamond pastes or slurries on specialized pads, Chemo-Mechanical Polishing (CMP) for semiconductor wafers.

- Relevance: Optical mirrors, high-performance bearings, semiconductor wafers, and components requiring minimal surface-induced light scattering or friction.

- Edge Chamfering/Rounding:

- Purpose: To remove sharp edges, which can be stress concentration points and prone to chipping, especially in brittle materials like SiC. Chamfered or rounded edges improve strength and handling safety.

- Methods: Specialized grinding wheels, diamond files, or sometimes laser ablation.

- Relevance: Most SiC components, particularly wafers, tiles, and parts that will be handled or assembled.

- Cleaning:

- Purpose: To remove any residual abrasive particles, coolants, machining debris, or contaminants from the SiC surface.

- Methods: Ultrasonic cleaning in deionized water or specific solvents, precision cleaning protocols for semiconductor-grade components.

- Relevance: Universally required, but stringency varies with application (e.g., ultra-high purity cleaning for semiconductor processing equipment).

- Annealing/Heat Treatment:

- Purpose: Occasionally used to relieve internal stresses induced during machining, or to modify material microstructure in some specific SiC grades or applications (though less common for fully sintered SiC).

- Methods: Controlled heating in a furnace with a specific temperature profile and atmosphere.

- Relevance: Specific cases where stress relief is critical and cannot be managed by machining parameters alone.

- Sealing or Coating (Less Common for Pure SiC, More for Porous Grades or Composites):

- Purpose: For porous SiC grades (like some reaction-bonded types), sealing might be done to reduce permeability. Coatings (e.g., CVD diamond, other ceramics) can be applied to enhance specific surface properties like extreme wear resistance or chemical inertness further, though dense SiC often provides these inherently.

- Methods: Impregnation with sealants, Chemical Vapor Deposition (CVD), Physical Vapor Deposition (PVD).

- Relevance: Specialized applications requiring enhanced surface functionalities beyond inherent SiC properties or for improving performance of less dense SiC variants.

The necessity and extent of these post-processing steps significantly influence the final cost and lead time of SiC components for industrial applications. Procurement managers and engineers should discuss these requirements in detail with their suppliers. Sicarb Tech and its network of specialized SiC factories in Weifang are equipped to handle a range of post-processing needs, ensuring that the final customized silicon carbide components meet all performance and quality specifications. Their integrated process, from raw material to finished and post-processed parts, provides a streamlined solution for obtaining high-quality SiC products.

Frequently Asked Questions (FAQ) about SiC Cutting Machines

Technical buyers, engineers, and procurement managers often have specific questions when considering Silicon Carbide components and the machinery used to produce them. Here are some common queries with concise, practical answers:

1. What are the primary challenges in cutting Silicon Carbide (SiC), and how do modern machines address them?

Silicon Carbide’s extreme hardness (ranking just below diamond) and brittleness are the primary challenges. This makes it difficult to machine without causing chipping, micro-cracks, or rapid tool wear.

- Hardness: Modern SiC cutting machines address this by using superabrasives, primarily diamond tooling (for saws, grinders) or high-energy processes. Diamond wire saws and diamond grinding wheels are specifically designed to abrade SiC effectively.

- Brittleness: To manage brittleness and prevent fractures, machines employ strategies like:

- Low-stress cutting methods: Diamond wire cutting SiC applies relatively low force, minimizing sub-surface damage.

- Non-contact cutting: Laser cutting silicon carbide avoids mechanical stress, though thermal stress needs management (e.g., using ultrashort pulse lasers to reduce the heat-affected zone).

- Optimized parameters: Precise control of feed rates, cutting speeds, and depth of cut is crucial.

- Effective cooling: Coolants dissipate heat and remove abrasive particles, reducing thermal shock and tool wear.

- Rigid machine construction: Minimizes vibrations that can exacerbate cracking.

- Tool Wear: Diamond tools still wear when cutting SiC. Advanced machines may incorporate tool wear monitoring systems and use high-quality, durable diamond abrasives. Laser systems require maintenance of optics.

2. How does the choice of SiC cutting machine affect the cost and lead time of custom SiC components?

The choice of cutting machine and subsequent post-processing significantly impacts cost and lead time:

- Cutting Speed & Complexity:

- Abrasive Waterjet: Relatively fast for rough cutting thick sections or complex 2D shapes but may require significant secondary grinding for precision, adding to cost and time.

- Diamond Sawing (Blade/Wire): Wire sawing is slower per cut but good for batch wafering with minimal material loss. Blade sawing is faster for simpler cuts.

- Laser Cutting: Can be very fast for intricate patterns or scribing, but initial equipment cost is high. Throughput depends on material thickness and laser power.

- Grinding: Can be time-consuming, especially for achieving very tight tolerances and fine finishes, adding to the cost.

- Material Utilization (Kerf Loss):

- Diamond wire saws offer minimal kerf loss, maximizing usable material from expensive SiC boules, which is cost-effective for wholesale SiC components.

- Blade saws and abrasive waterjets have larger kerf losses.

- Tooling Costs & Wear Rate: Diamond tools are expensive, and their wear rate contributes to operational costs. Laser systems have consumable optics and require maintenance.

- Precision & Post-Processing: Achieving tighter tolerances and finer surface finishes usually requires multiple steps (e.g., initial cutting followed by precision grinding and lapping/polishing). Each additional step adds to the cost and lead time.

- Automation & Labor: Highly automated SiC cutting machines can reduce labor costs and improve consistency but involve higher capital investment.

Partnering with a knowledgeable supplier like Sicarb Tech, who can optimize the entire process from material selection to final cutting and finishing, is crucial for managing costs and lead times effectively for custom SiC product procurement. Their expertise helps in selecting the most efficient cutting strategy for a given component and application.

3. What should I look for when choosing a supplier for custom SiC components that require precision cutting?

Selecting the right supplier is critical for obtaining high-quality, reliable customized silicon carbide components. Key factors include:

- Technical Expertise & Experience:

- Deep understanding of SiC material grades and their properties.

- Proven experience in machining SiC to tight tolerances and complex geometries.

- Knowledge of various SiC cutting technologies and their appropriate applications.

- Equipment & Capabilities:

- Access to a range of modern SiC cutting machines (diamond saws, lasers, grinders, etc.) to suit different requirements.

- In-house or tightly controlled post-processing capabilities (grinding, lapping, polishing, cleaning).

- Robust metrology and quality control systems (e.g., CMM, surface profilometers, optical inspection).

- Material Quality & Sourcing:

- Ability to source high-quality SiC raw materials appropriate for your application.

- Traceability of materials.

- Design for Manufacturability (DFM) Support:

- Willingness and ability to collaborate on design optimization to improve manufacturability and reduce costs.

- Quality Certifications:

- Relevant certifications (e.g., ISO 9001) demonstrating a commitment to quality management.

- Capacity & Lead Times:

- Ability to meet your volume requirements and delivery schedules.

- Location and Support:

- Consider suppliers like Sicarb Tech, located in Weifang City, a major hub for SiC production. SicSino not only offers custom parts but also benefits from its role within the Chinese Academy of Sciences Innovation Park, providing access to advanced technologies and a strong talent pool. They emphasize reliable quality and supply assurance.

- Technology Transfer Options: For businesses looking to establish their own SiC production, SicSino uniquely offers technology transfer for professional SiC production, including turnkey project services. This indicates a profound level of expertise.

By carefully evaluating these aspects, technical procurement professionals, OEMs, and distributors can find a reliable partner for their industrial SiC cutting equipment needs and custom component sourcing.

Conclusion: The Enduring Value of Precision in SiC Component Manufacturing

The journey through the intricacies of SiC cutting machines reveals a landscape where precision, material science, and advanced engineering converge. For industries pushing the boundaries of performance – from semiconductors to aerospace, energy to industrial manufacturing – the ability to shape Silicon Carbide into highly reliable, custom components is not just an advantage, but a necessity. The exceptional hardness, thermal stability, and wear resistance of SiC are unlocked and made accessible through sophisticated cutting technologies like diamond wire sawing, laser ablation, and precision grinding.

Choosing the right SiC cutting technology and, crucially, the right manufacturing partner, directly impacts the quality, cost-effectiveness, and timely delivery of critical components. Factors like achievable tolerances, surface finish, design for manufacturability, and post-processing needs must be carefully considered by engineers and procurement managers.

In this demanding field, companies like Sicarb Tech stand out. Rooted in the technological powerhouse of the Chinese Academy of Sciences and strategically located in Weifang, the epicenter of China’s SiC industry, SicSino offers more than just component manufacturing. They provide a gateway to advanced SiC production technologies, supporting local enterprises and offering global partners access to high-quality, cost-competitive customized silicon carbide components. Their commitment to an integrated process—from material expertise and design consultation to cutting-edge machining and evaluation—ensures that clients receive parts optimized for their specific applications. Furthermore, their unique offering of technology transfer for setting up specialized SiC factories underscores their deep expertise and commitment to advancing the SiC industry.

As the demand for high-performance materials continues to surge, the role of expert SiC machining and reliable suppliers will only grow in importance. By partnering with knowledgeable and well-equipped specialists, businesses can confidently integrate the superior properties of custom silicon carbide into their most demanding industrial environments, driving innovation and achieving new levels of operational excellence.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.