Unlocking a New Era of Performance: The Transformative Potential of Nano Silicon Carbide

Share

In the relentless pursuit of materials that can withstand extreme conditions and deliver unprecedented performance, nano silicon carbide (nano SiC) emerges as a revolutionary contender. This advanced ceramic material, engineered at the nanoscale, offers a remarkable suite of properties that are redefining possibilities across a multitude of high-stakes industries. From enhancing the efficiency of semiconductor manufacturing to fortifying components in aerospace and energy sectors, custom nano silicon carbide products are essential for applications demanding exceptional thermal conductivity, mechanical strength, and chemical inertness. As industries push the boundaries of innovation, the unique attributes of nano SiC are not just beneficial but are increasingly becoming indispensable.

The drive for miniaturization, coupled with the need for materials that can operate reliably under harsh environments, has propelled nano SiC into the spotlight. Unlike its bulk counterparts, nano SiC powders and components derived from them exhibit enhanced properties due to their incredibly fine grain structures and increased surface area. This translates to improved sinterability, greater hardness, and superior wear resistance, opening doors to applications previously thought unattainable. For procurement managers, engineers, and technical buyers, understanding the intricacies of nano silicon carbide is crucial for making informed decisions that can lead to significant advancements in product design, durability, and overall operational efficiency. At Sicarb Tech, we are at the forefront of harnessing the power of this extraordinary material, offering bespoke nano SiC solutions tailored to the exacting demands of modern industry.

The Science of Small: What Makes Nano Silicon Carbide Unique?

Nano silicon carbide refers to SiC particles with dimensions typically less than 100 nanometers. This reduction in particle size to the nanoscale unlocks a host of quantum mechanical and surface-area effects that dramatically alter and often enhance the material’s intrinsic properties compared to micro-sized or bulk silicon carbide. The key to its uniqueness lies in its atomic structure and the consequences of its nanometric scale.

At its core, silicon carbide (SiC) is a compound of silicon and carbon, forming a very strong, covalently bonded crystal lattice. Common polytypes include cubic (β-SiC) and hexagonal (α-SiC). When produced or processed into nanoparticles, several critical changes occur:

- Increased Surface Area to Volume Ratio: As particle size decreases, the proportion of atoms on the surface increases exponentially. This vast surface area enhances reactivity, allows for lower sintering temperatures, and provides more sites for interaction with matrix materials in composites.

- Quantum Confinement Effects: In extremely small nanoparticles (typically below 10-20 nm), quantum confinement can lead to changes in electronic and optical properties. This is particularly relevant for applications like quantum dots or specialized sensors.

- Grain Boundary Strengthening (Hall-Petch Effect): In consolidated nanocrystalline SiC materials, the high density of grain boundaries impedes dislocation movement, leading to significantly increased hardness and strength compared to coarser-grained SiC.

- Enhanced Sinterability: Nano SiC powders can be sintered to high densities at lower temperatures and shorter times than micron-sized powders. This is due to the higher driving force for densification provided by the large surface energy of nanoparticles, leading to energy savings and the potential to retain finer, more uniform microstructures.

- Improved Homogeneity: The use of nano SiC powders can lead to more uniform microstructures in the final ceramic components, reducing flaws and enhancing mechanical reliability.

These unique characteristics translate into a range of superior material properties:

- Exceptional Hardness and Wear Resistance: Nano SiC is one of the hardest materials available, making it ideal for wear-resistant coatings, cutting tools, and abrasive applications.

- High Thermal Conductivity: Despite its ceramic nature, SiC exhibits excellent thermal conductivity, which is often retained or even enhanced at the nanoscale, crucial for heat dissipation in electronics and high-temperature applications.

- Superior Strength at High Temperatures: Nano SiC maintains its mechanical strength and creep resistance at elevated temperatures (often exceeding 1600∘C), outperforming most metals and other ceramics.

- Excellent Chemical Inertness: It is highly resistant to corrosion and oxidation, even in aggressive chemical and high-temperature environments.

- Tailorable Electrical Properties: While inherently a semiconductor, the electrical conductivity of SiC can be tailored through doping and its nanostructure, allowing for applications ranging from insulators to conductive elements.

Sicarb Tech, leveraging its deep expertise in technical ceramics and its strategic position within Weifang City, China’s silicon carbide manufacturing hub, is adept at producing and utilizing nano SiC powders to create custom components that fully exploit these unique nanoscale advantages. Our connection with the Chinese Academy of Sciences ensures that we are at the cutting edge of nano SiC material science and application.

Pushing Boundaries: Key Applications of Nano Silicon Carbide

The exceptional properties of nano silicon carbide have paved the way for its adoption in a diverse array of demanding industrial applications. Its ability to enhance performance, improve durability, and enable new functionalities makes it a critical material for industries striving for technological breakthroughs. Wholesale buyers and OEMs are increasingly specifying nano SiC for components where conventional materials fall short.

1. Advanced Composites and Structural Reinforcement: Nano SiC particles are extensively used as a reinforcement phase in metal matrix composites (MMCs), ceramic matrix composites (CMCs), and polymer matrix composites (PMCs).

- MMCs (e.g., Aluminum-SiC): Adding nano SiC to aluminum or magnesium alloys significantly increases their yield strength, tensile strength, hardness, and wear resistance while maintaining low density. These are sought after in aerospace SiC components and automotive parts for lightweighting and performance.

- CMCs (e.g., SiC-SiC): Nano SiC can be used to create finer microstructures in SiC-fiber reinforced SiC matrix composites, enhancing their toughness and thermal shock resistance for applications like gas turbine components, heat exchangers, and high-temperature furnace parts.

- PMCs: Dispersing nano SiC in polymers can improve their mechanical strength, thermal stability, and wear resistance, beneficial for high-performance coatings, adhesives, and engineering plastics.

2. High-Performance Coatings: Nano SiC is a preferred material for creating ultra-hard, wear-resistant, and corrosion-resistant coatings.

- Cutting Tools and Molds: Coatings of nano SiC or diamond-like carbon (DLC) incorporating SiC nanoparticles extend the life of cutting tools, dies, and molds used in industrial manufacturing.

- Protective Layers: Applied via thermal spray or PVD/CVD techniques, nano SiC coatings protect underlying materials from abrasion, erosion, and chemical attack in harsh environments, such as in chemical processing equipment or pump components.

- Biomedical Implants: Biocompatible nano SiC coatings can improve the wear resistance and longevity of medical implants.

3. Semiconductor Manufacturing and Electronics: The semiconductor industry leverages nano SiC for its thermal management capabilities and stability.

- CMP Slurries: Nano SiC particles are used in Chemical Mechanical Planarization (CMP) slurries for polishing silicon wafers and other semiconductor materials, achieving superior surface flatness.

- Thermal Interface Materials (TIMs): Nano SiC, with its high thermal conductivity, is incorporated into TIMs to efficiently dissipate heat from microprocessors and power electronics.

- High-Frequency Devices: The unique electronic properties of certain SiC polytypes at the nanoscale are being explored for next-generation high-frequency and high-power electronic devices.

4. Energy Storage and Conversion: Nano SiC plays a role in enhancing the performance and safety of energy systems.

- Lithium-Ion Batteries: As an anode material or coating, nano SiC can improve the cycle life, charging rate, and safety of lithium-ion batteries by accommodating volume changes and enhancing conductivity.

- Thermoelectric Devices: The thermoelectric properties of nano SiC can be optimized for waste heat recovery and power generation.

- Catalysis: The high surface area and thermal stability make nano SiC an excellent catalyst support for various chemical reactions, including in energy applications like hydrogen production.

5. Abrasives and Polishing: Due to its extreme hardness, nano SiC is used in high-precision grinding, lapping, and polishing applications where achieving exceptionally smooth surfaces and tight tolerances is critical, such as in optics and advanced ceramics finishing.

The table below highlights some key industries and the specific advantages nano SiC brings:

| Industry Sector | Key Nano SiC Applications | Advantages Gained Through Nano SiC Integration |

|---|---|---|

| Aerospace | Lightweight MMCs, Thermal protection system components, High-temperature sensors | Reduced weight, Increased strength-to-weight ratio, Enhanced thermal stability |

| Automotive | Engine components, Brake systems, Wear-resistant parts in MMCs | Improved fuel efficiency, Durability, Reduced emissions |

| Semiconductors | CMP slurries, Wafer handling components, Heat sinks | Precision polishing, High thermal conductivity, Purity |

| Energy | Battery components, Fuel cell parts, Thermoelectric devices | Enhanced efficiency, Improved cycle life, High-temperature operation |

| Industrial Manufacturing | Cutting tools, Wear-resistant coatings, Pump seals, Nozzles | Extended tool life, Reduced downtime, Improved process efficiency |

| Chemical Processing | Seals, Valves, Linings for corrosive environments | Superior chemical resistance, High wear resistance |

Sicarb Tech, with its comprehensive understanding of custom SiC components and the nuances of nano silicon carbide powder processing, is well-equipped to partner with businesses in these demanding sectors. Our ability to provide custom nano SiC parts ensures that clients can fully leverage the material’s potential for their specific application needs, backed by the robust supply chain and technological expertise of Weifang’s SiC industrial cluster.

Advantages of Custom Nano Silicon Carbide Components

Opting for custom-designed nano silicon carbide components, rather than off-the-shelf solutions, offers significant advantages for industries requiring peak performance and tailored functionality. The inherent properties of nano SiC are already exceptional, but customization amplifies these benefits by aligning the material’s characteristics and the component’s geometry precisely with the application’s demands. This is particularly crucial for technical procurement professionals and OEMs looking to gain a competitive edge.

The primary benefits of customizing nano SiC components include:

- Optimized Performance for Specific Conditions:

- Tailored Thermal Management: Custom designs can optimize heat dissipation paths, crucial for semiconductor applications SiC and power electronics. The geometry, density, and even the blend of nano SiC can be adjusted to achieve specific thermal conductivity profiles.

- Enhanced Wear Resistance: For applications like custom nozzles, seals, or bearings, the component can be designed to maximize wear life in its specific operational environment, considering factors like contact pressure, abrasive media, and temperature. Sicarb Tech can engineer components where the highest wear resistance is concentrated in critical areas.

- Specific Chemical Inertness: While nano SiC is broadly inert, specific contaminants or chemical concentrations at extreme temperatures might require subtle adjustments in material purity or density, achievable through custom formulation and processing.

- Precision Engineering and Complex Geometries:

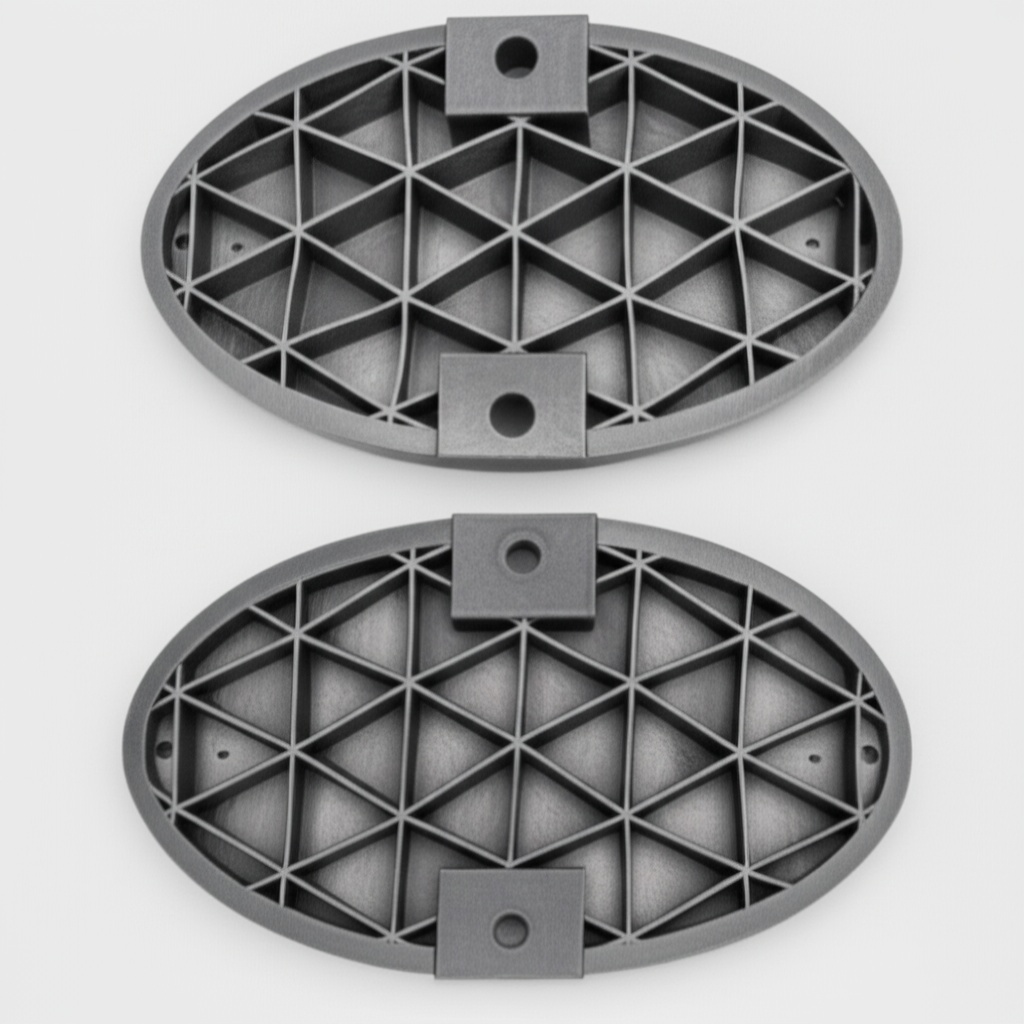

- Complex Shapes: Advanced manufacturing techniques, guided by expert design, allow for the creation of intricate nano SiC parts that would be impossible with traditional machining of bulk materials. This is vital for miniaturized devices or components with complex internal features.

- Tight Tolerances: Custom manufacturing ensures that components meet exact dimensional specifications, critical for integration into larger assemblies, especially in aerospace SiC components and precision machinery.

- Integration Features: Custom components can be designed with built-in features for easier assembly, such as specific mounting points, channels, or interfaces, reducing overall system complexity and cost.

- Improved Material Efficiency and Cost-Effectiveness (Long-Term):

- Reduced Material Waste: Designing components to near-net shape with nano SiC powders, especially using advanced forming techniques, can minimize material waste compared to subtractive manufacturing from larger blocks.

- Extended Component Lifespan: Components tailored to their exact operational stresses and environmental challenges typically last longer, reducing replacement frequency, downtime, and long-term operational costs. This is a key consideration for industrial SiC solutions.

- System-Level Benefits: A custom nano SiC part can enhance the performance and reliability of the entire system it’s part of, leading to greater overall efficiency and value.

- Prototyping and Iterative Design:

- Working with a specialized supplier like Sicarb Tech allows for rapid prototyping and iterative design improvements. This flexibility is crucial when developing new technologies or optimizing existing ones, allowing engineers to test and refine nano SiC components quickly.

- Proprietary Solutions:

- Custom components can provide a competitive advantage by enabling proprietary designs that are difficult for competitors to replicate. This is particularly relevant for OEMs developing cutting-edge products.

The table below summarizes the advantages of custom nano SiC components versus standard options:

| Feature | Standard SiC Components | Custom Nano SiC Components (e.g., from SicSino) |

|---|---|---|

| Design Flexibility | Limited to available shapes and sizes | High; tailored to specific geometries and functional requirements |

| Performance | General-purpose; may be over or under-engineered | Optimized for the specific application; maximises desired properties |

| Material Utilization | Can involve significant machining waste | Near-net-shape possibilities, reducing waste |

| Integration | May require adapters or modifications for assembly | Can be designed for seamless integration |

| Lifecycle Cost | Potentially lower initial cost, but may have shorter life | Higher initial design investment, often lower total cost of ownership due to longevity & performance |

| Competitive Edge | Uses commonly available parts | Enables unique, high-performance proprietary solutions |

Choosing custom nano silicon carbide products means investing in a solution that is meticulously engineered for your needs. Sicarb Tech, backed by the extensive capabilities of the Chinese Academy of Sciences National Technology Transfer Center and the dynamic SiC ecosystem in Weifang, specializes in translating complex engineering requirements into high-performance custom nano SiC parts. Our integrated approach, from material science to final component manufacturing, ensures that our clients receive parts that deliver maximum value and performance.

Synthesis and Processing: Creating Nano Silicon Carbide

The journey from raw materials to high-performance nano silicon carbide components is a sophisticated process involving specialized synthesis methods for producing nano SiC powders and advanced consolidation techniques to form dense, engineered parts. The choice of synthesis route significantly impacts the powder’s characteristics, such as particle size distribution, purity, crystallinity, and morphology, which in turn influence the properties of the final sintered component.

Common Synthesis Methods for Nano SiC Powders:

- Acheson Process (Modified): While the traditional Acheson process produces industrial-grade SiC, modifications can yield finer particles. However, achieving true nanoscale with high purity via this carbothermal reduction of silica with carbon at very high temperatures (>2000∘C) is challenging and often requires extensive post-processing (milling, classification).

- Chemical Vapor Synthesis (CVS) / Chemical Vapor Reaction (CVR): This method involves the reaction of gaseous precursors (e.g., silanes like SiH4 or chlorosilanes like SiCl4, and hydrocarbons like CH4 or C2H2) at high temperatures. CVS can produce high-purity, fine, and unagglomerated nano SiC powders with controlled stoichiometry. Laser pyrolysis and plasma synthesis are variants of this approach.

- Example Reaction (simplified): SiH4(g)+CH4(g)→SiC(s)+4H2(g)

- Sol-Gel Process: This wet chemical route involves the hydrolysis and polycondensation of silicon alkoxides and a carbon source. The resulting gel is then heat-treated (pyrolyzed and carbothermally reduced) to form SiC nanoparticles. This method offers good control over purity and particle size.

- Polymer Precursor Route: Organosilicon polymers (e.g., polysilanes, polycarbosilanes) are synthesized, shaped, and then pyrolyzed in an inert or reactive atmosphere to convert them into SiC. This route is particularly useful for producing SiC fibers and coatings, and can yield amorphous or nanocrystalline SiC.

- High-Energy Ball Milling: This mechanical attrition method involves milling coarser SiC powders (or a mixture of silicon and carbon) in a high-energy mill. The intense mechanical forces lead to particle size reduction down to the nanoscale. However, contamination from milling media can be a concern.

- Combustion Synthesis / Self-Propagating High-Temperature Synthesis (SHS): Highly exothermic reactions between reactants (e.g., silicon and carbon powders) are initiated, and a combustion wave propagates through the mixture, forming SiC. This can be a rapid and energy-efficient method, often yielding fine powders.

Key Considerations in Nano SiC Powder Production:

- Particle Size and Distribution: Crucial for sinterability and final microstructure.

- Purity: Impurities can degrade mechanical, thermal, and electrical properties.

- Crystallinity and Polytype: β-SiC (cubic) is often preferred for sintering, while different polytypes may be desired for specific electronic applications.

- Degree of Agglomeration: Hard agglomerates are difficult to break down and can lead to defects in sintered parts.

- Cost: Some synthesis routes are more expensive than others, impacting the final product cost.

Consolidation and Processing of Nano SiC Powders into Components:

Once nano SiC powders are synthesized, they must be consolidated into dense components. This is challenging due to the material’s high melting point, strong covalent bonding, and the tendency of nanoparticles to agglomerate.

- Sintering:

- Pressureless Sintering (PLS): Requires sintering aids (e.g., boron, carbon, alumina, yttria) and very high temperatures (typically 2000−2200∘C). Achieving full density with nano powders can be difficult without grain growth.

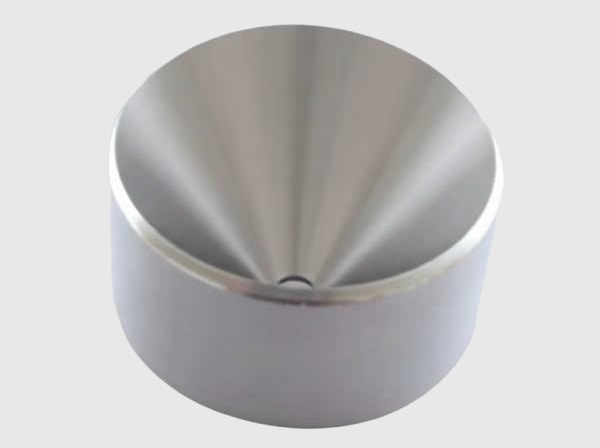

- Hot Pressing (HP): Simultaneous application of heat and uniaxial pressure. Results in higher densities and finer microstructures than PLS, but is limited to simpler shapes.

- Hot Isostatic Pressing (HIP): Applies heat and isostatic gas pressure, excellent for complex shapes and achieving near-full density. Often used as a post-sintering step.

- Spark Plasma Sintering (SPS) / Field Assisted Sintering Technology (FAST): A relatively new technique that uses pulsed DC current and uniaxial pressure. Allows for very rapid heating and cooling, leading to high densities at lower temperatures and shorter times, effectively preserving nanocrystalline structures. This is a key technology for advanced material solutions using nanoparticles.

- Reaction Bonding (RB-SiC) / Infiltration: A porous preform of SiC and carbon is infiltrated with molten silicon. The silicon reacts with the carbon to form new SiC, bonding the original particles. The final material contains some free silicon. While not always producing true “nano-structured” SiC throughout, nano SiC powders can be used in the initial preform.

- Additive Manufacturing (e.g., Binder Jetting, Stereolithography): Emerging techniques for creating complex SiC parts layer by layer using nano SiC powders mixed with binders, followed by debinding and sintering. These offer great design freedom for custom SiC components.

Sicarb Tech has extensive expertise in both the selection and processing of nano SiC powders. Our capabilities in Weifang, the heart of China’s SiC industry, benefit from access to various advanced synthesis and consolidation technologies. We assist clients in choosing the optimal production route for their custom nano SiC parts, ensuring the desired properties and performance are achieved, leveraging our deep understanding of silicon carbide manufacturing processes from powder to product. Our association with the Chinese Academy of Sciences provides us with insights into the latest innovations in nano SiC synthesis and processing, which we translate into tangible benefits for our customers.

From Powder to Part: Design and Manufacturing of Custom Nano SiC Components

Transforming nano silicon carbide powder into functional, high-performance custom components is a multi-stage process that demands expertise in material science, ceramic engineering, and precision manufacturing. The journey involves careful design considerations, selection of appropriate forming and sintering techniques, and meticulous post-processing to meet the stringent requirements of industries like aerospace, semiconductors, and high-temperature processing. At Sicarb Tech, we leverage our deep technical knowledge and the robust manufacturing ecosystem of Weifang to deliver bespoke custom nano SiC parts.

Design Considerations for Nano SiC Components:

Designing with nano SiC requires a different mindset than with metals or even conventional ceramics due to its hardness, brittleness (though toughness can be enhanced at the nanoscale and with composites), and specific manufacturing constraints.

- Manufacturability: Complex geometries are achievable, especially with techniques like Spark Plasma Sintering (SPS) or additive manufacturing routes, but designs should aim to minimize sharp internal corners, abrupt changes in thickness, and features that could introduce stress concentrations.

- Geometry Limits & Wall Thickness: While nano SiC allows for finer features, minimum wall thickness is dictated by the forming process and handling strength of the green or sintered body. Thin walls can be challenging to produce without defects.

- Stress Points & Load Distribution: Finite Element Analysis (FEA) is often employed to identify potential stress points. Designs should aim to distribute loads evenly to mitigate the risk of fracture. Fillets and radii are preferred over sharp edges.

- Tolerances & Surface Finish: Extremely tight tolerances and smooth surface finishes (often to the nanometer scale for optical applications) are achievable but add to the cost and complexity. Realistic tolerances should be specified based on functional requirements.

- Joining & Assembly: If the nano SiC component is part of a larger assembly, methods for joining it to other materials (e.g., brazing, diffusion bonding, mechanical fastening) must be considered during the design phase.

- Material Selection within Nano SiC Grades: Even within “nano SiC,” variations in powder synthesis, purity, and the use of sintering aids can lead to different final properties. The specific grade or composition must be matched to the application’s thermal, mechanical, electrical, and chemical demands.

Manufacturing Process Overview:

- Powder Preparation & Mixing: High-quality nano SiC powder is selected. If sintering aids or other constituents are required (e.g., for composites), they are intimately mixed with the SiC powder using techniques like ball milling or attrition milling to ensure homogeneity. Binders and plasticizers may be added for certain forming methods.

- Forming (Shaping the Green Body):

- Pressing (Uniaxial, Isostatic): Powder is compacted in a die. Suitable for simpler shapes.

- Slip Casting / Slurry Casting: A stable suspension (slip) of nano SiC powder is poured into a porous mold. Suitable for complex shapes.

- Extrusion: For producing parts with constant cross-sections, like rods and tubes.

- Injection Molding (Ceramic Injection Molding – CIM): Nano SiC powder is mixed with a thermoplastic binder, molded, and then the binder is removed. Excellent for complex, high-volume parts.

- Additive Manufacturing (3D Printing): Techniques like binder jetting, material jetting, or vat polymerization are increasingly used for intricate prototypes and small production runs of custom SiC components.

- Debinding (Binder Removal): If binders were used in forming, the green parts undergo a controlled heating process to carefully burn out the organic binders before sintering.

- Sintering / Densification: The porous green body is heated to high temperatures (often under pressure, as in HP, HIP, or SPS) to cause the nanoparticles to bond and the part to densify, achieving high strength and the desired microstructure. This is a critical step where the unique properties of nanocrystalline silicon carbide are locked in.

- Machining and Finishing (Post-Sintering):

- Due to its extreme hardness, sintered SiC is very difficult to machine. Diamond tooling is exclusively used.

- Grinding: To achieve precise dimensions and tolerances.

- Lapping & Polishing: For applications requiring ultra-smooth surfaces (e.g., mirrors, semiconductor equipment parts, seals). CMP can be used for nanometer-level finishes.

- Laser Machining: Can be used for drilling small holes or creating intricate surface features.

- Electrical Discharge Machining (EDM): Applicable if the SiC grade has sufficient electrical conductivity.

- Cleaning & Inspection: Parts are thoroughly cleaned and inspected for dimensional accuracy, surface quality, and internal defects using techniques like CMM, SEM, X-ray, or ultrasonic testing.

The table below outlines typical forming and finishing methods for nano SiC components:

| Manufacturing Stage | Technique Examples | Key Considerations for Nano SiC |

|---|---|---|

| Powder Preparation | Ball Milling, Attrition Milling, Spray Drying | Homogeneity, Deagglomeration, Binder compatibility |

| Forming | Isostatic Pressing, CIM, Slip Casting, Additive Manufacturing | Shape complexity, Green density, Dimensional control |

| Debinding | Thermal Debinding, Solvent Debinding | Slow, controlled removal to prevent defects |

| Sintering | SPS, HIP, Pressureless Sintering (with aids) | Density, Grain size control, Temperature, Atmosphere, Pressure |

| Machining | Diamond Grinding, Lapping, Polishing, Laser Ablation, EDM | Extreme hardness, Tool wear, Achievable tolerances |

| Inspection | CMM, SEM, NDT (X-ray, Ultrasonic) | Defect detection, Dimensional verification, Surface roughness |

Sicarb Tech provides comprehensive customizing support, guiding clients from the initial design concept through to the final delivered nano SiC component. Our team in Weifang, a recognized hub for China’s silicon carbide customizable parts factories, possesses the integrated process knowledge – covering material selection, process optimization, design for manufacturing, and advanced measurement and evaluation technologies – to meet diverse and challenging customization needs. We ensure that your custom nano SiC parts are not only manufactured to specification but also optimized for performance and reliability.

Addressing Challenges in Nano SiC Utilization and Manufacturing

While nano silicon carbide offers a wealth of advantages, its widespread adoption and efficient manufacturing are not without challenges. These hurdles often stem from the very nanoscale characteristics that provide its benefits, as well as the inherent properties of silicon carbide itself. Understanding these challenges is crucial for both manufacturers and end-users to develop effective mitigation strategies and unlock the full potential of this advanced material.

Key Challenges:

- Powder Handling and Agglomeration:

- Issue: Nano SiC powders have a very high surface area and energy, making them prone to forming agglomerates (clumps of particles). These agglomerates can be difficult to break down and can persist through processing, leading to inhomogeneous microstructures, porosity, and reduced mechanical properties in the final component.

- Mitigation:

- Surface modification of nanoparticles (e.g., using surfactants or coatings).

- Advanced dispersion techniques (e.g., ultrasonic agitation, high-shear mixing).

- Controlled powder handling environments to minimize moisture and electrostatic attraction.

- Use of spray drying to produce flowable granules of deagglomerated nanopowders.

- Achieving Full Densification without Grain Growth:

- Issue: Sintering nano SiC powders to full density often requires high temperatures, which can lead to undesirable grain growth. Coarsening of the nanostructure negates some of the benefits of using nanoparticles in the first place (e.g., reduced Hall-Petch strengthening).

- Mitigation:

- Employing advanced sintering techniques like Spark Plasma Sintering (SPS) or Hot Isostatic Pressing (HIP), which can achieve densification at lower temperatures and shorter times.

- Careful selection and use of sintering aids that promote densification without significantly accelerating grain growth.

- Two-step sintering processes.

- Machining and Finishing Complexity:

- Issue: Sintered SiC is extremely hard and brittle, making it very difficult and costly to machine to precise tolerances. Tool wear is rapid, and achieving fine surface finishes requires specialized techniques.

- Mitigation:

- Near-net-shape forming techniques (e.g., Ceramic Injection Molding, additive manufacturing) to minimize the amount of material that needs to be removed.

- Advanced machining processes: diamond grinding, lapping, polishing, laser ablation, Electrical Discharge Machining (EDM) for conductive grades.

- Designing parts with machining in mind, avoiding features that are unnecessarily difficult to create.

- Expertise in tolerance, surface finish & dimensional accuracy is critical.

- Cost of Nano SiC Powders and Processing:

- Issue: The synthesis of high-quality, unagglomerated nano SiC powders can be expensive compared to conventional micron-sized SiC. Advanced consolidation and machining processes also add to the cost.

- Mitigation:

- Ongoing research into more cost-effective synthesis routes for nano SiC.

- Optimizing manufacturing processes for higher yields and reduced waste.

- Focusing on applications where the performance benefits justify the cost.

- Partnering with experienced suppliers like Sicarb Tech, who leverage the economies of scale and specialized expertise within China’s SiC manufacturing hub to offer cost-competitive customized silicon carbide components.

- Brittleness and Fracture Toughness:

- Issue: Like most ceramics, SiC is inherently brittle, though nanocrystalline SiC can exhibit improved toughness compared to coarse-grained counterparts. Susceptibility to catastrophic failure from small flaws is a concern.

- Mitigation:

- Incorporating nano SiC into composite materials (e.g., CMCs, MMCs) to enhance toughness through mechanisms like crack deflection and fiber pull-out.

- Careful process control to minimize flaws (pores, inclusions) that can act as fracture initiation sites.

- Design strategies that manage stress concentrations.

- Development of self-healing SiC materials.

- Quality Control and Characterization:

- Issue: Characterizing nanoparticles and nanostructured materials requires advanced analytical techniques to assess particle size, distribution, morphology, phase purity, and defects at the nanoscale.

- Mitigation:

- Utilizing sophisticated characterization tools: Transmission Electron Microscopy (TEM), Scanning Electron Microscopy (SEM), X-ray Diffraction (XRD), Atomic Force Microscopy (AFM), surface area analyzers (BET).

- Establishing stringent quality control protocols throughout the manufacturing process, from powder synthesis to final component inspection. Sicarb Tech prides itself on its robust measurement and evaluation technologies.

- Scaling Production:

- Issue: Transitioning from laboratory-scale production of nano SiC powders and components to large-scale, consistent industrial manufacturing can be challenging.

- Mitigation:

- Investment in scalable synthesis and processing technologies.

- Process automation and control.

- Developing a reliable supply chain for high-quality raw materials and nano SiC powders. Companies like Sicarb Tech play a vital role in assisting local enterprises in Weifang to achieve large-scale production.

Overcoming these challenges requires a deep understanding of materials science, ceramic processing, and engineering design. It also necessitates collaboration between researchers, manufacturers, and end-users. As a key player in the Weifang SiC cluster, Sicarb Tech is actively involved in addressing these challenges, continually refining our processes and leveraging the collective expertise of the region and the Chinese Academy of Sciences to deliver superior nano silicon carbide solutions. Our integrated approach, encompassing material, process, design, and evaluation technologies, positions us to help clients navigate the complexities of nano SiC utilization.

Choosing Your Partner: Selecting the Right Nano Silicon Carbide Supplier

Selecting the right supplier for nano silicon carbide products, whether powders or custom components, is a critical decision that can significantly impact the success of your project and the performance of your end products. The specialized nature of nano SiC demands a supplier with deep technical expertise, robust manufacturing capabilities, stringent quality control, and a commitment to customer collaboration. For wholesale buyers, technical procurement professionals, OEMs, and distributors, a thorough evaluation process is essential.

Key Criteria for Evaluating a Nano SiC Supplier:

- Technical Expertise and R&D Capabilities:

- Material Science Knowledge: Does the supplier have a profound understanding of nano SiC synthesis, characterization, and the relationship between processing, microstructure, and properties?

- Engineering Support: Can they offer design assistance, material selection advice, and co-engineering solutions tailored to your specific application?

- Innovation: Is the supplier invested in R&D to improve nano SiC materials and manufacturing processes? Look for connections to research institutions, like Sicarb Tech‘s collaboration with the Chinese Academy of Sciences .

- Manufacturing Capabilities and Customization:

- Range of Technologies: Does the supplier possess a comprehensive suite of manufacturing technologies, from powder processing to forming (e.g., pressing, CIM, additive manufacturing) and advanced sintering (e.g., SPS, HIP)?

- Customization: Can they produce custom nano SiC parts to complex geometries and tight tolerances? Sicarb Tech emphasizes its ability to meet diverse customization needs.

- Scalability: Can they handle volumes from prototypes to large-scale production?

- Post-Processing: Do they offer in-house capabilities for machining, grinding, lapping, polishing, and coating?

- Quality Assurance and Certifications:

- Quality Management System: Is the supplier ISO 9001 certified or compliant with other relevant industry standards?

- Material Traceability: Can they provide full traceability of materials from raw inputs to finished products?

- Inspection and Testing: What are their capabilities for dimensional inspection, material characterization (e.g., SEM, XRD), and non-destructive testing (NDT)? Sicarb Tech highlights its measurement and evaluation technologies.

- Consistency: Can they ensure consistent quality from batch to batch?

- Supply Chain and Reliability:

- Location and Infrastructure: A supplier located in a major manufacturing hub, like Sicarb Tech in Weifang City (China’s SiC hub), often benefits from a well-established supply chain and skilled workforce. Weifang is home to over 40 SiC enterprises, accounting for over 80% of China’s total output.

- Lead Times: What are their typical lead times for custom orders, and are they reliable?

- Raw Material Sourcing: Do they have secure sources for high-quality nano SiC powders or precursors?

- Risk Management: What measures are in place to ensure continuity of supply?

- Cost-Effectiveness and Value:

- While initial price is a factor, consider the total cost of ownership. A slightly more expensive but higher-quality, more durable component from a reputable supplier can be more cost-effective in the long run.

- Sicarb Tech aims to offer higher-quality, cost-competitive customized silicon carbide components by leveraging its technological strengths and the industrial ecosystem in China.

- Customer Service and Support:

- Communication: Are they responsive and transparent in their communications?

- Collaboration: Are they willing to work closely with your team to understand your needs and solve problems?

- After-Sales Support: What kind of support do they offer after delivery?

- Experience and Reputation:

- Track Record: How long have they been working with nano SiC and similar advanced ceramics? Do they have case studies or testimonials from satisfied clients in your industry?

- Industry Standing: Are they recognized as experts in the field? The backing of the Chinese Academy of Sciences National Technology Transfer Center adds significant credibility to Sicarb Tech.

The following table offers a checklist for supplier evaluation:

| Evaluation Aspect | Key Questions to Ask | Desired Supplier Attributes |

|---|---|---|

| Technical Capability | What is your experience with nano SiC? What are your R&D efforts? Can you assist with design? | Deep material science knowledge, strong engineering team, innovative, collaborative. |

| Manufacturing Prowess | What forming, sintering, and finishing technologies do you use? Can you meet our complexity and tolerance needs? | Wide range of advanced equipment, proven customization capability, scalable production. |

| Quality Systems | Are you certified? What are your QC procedures? How do you ensure consistency? | ISO certification, comprehensive testing labs, robust QC protocols, full traceability. |

| Supply Chain & Reliability | What are your lead times? How do you ensure supply stability? | Reliable lead times, strong local supply network (e.g., Weifang hub for SicSino), risk mitigation plans. |

| Cost & Value | Can you provide a detailed cost breakdown? How does your product offer long-term value? | Transparent pricing, focus on total cost of ownership, demonstrable performance benefits. |

| Service & Support | How do you handle inquiries and technical support? What is your process for collaboration? | Responsive communication, dedicated technical support, collaborative approach. |

| Company Standing | Can you provide references or case studies? What is your industry reputation? | Proven track record, positive client feedback, respected in the advanced ceramics industry. |

Sicarb Tech embodies many of these desired attributes. Having introduced and implemented silicon carbide production technology since 2015, assisting local Weifang enterprises, we possess a domestic top-tier professional team. Our extensive array of technologies—material, process, design, measurement, and evaluation—along with an integrated process from materials to products, enables us to confidently meet diverse customization needs for nano silicon carbide components. Furthermore, for clients looking to establish their own SiC production, we offer technology transfer and turnkey project services. Choosing SicSino means partnering with a knowledgeable and reliable source committed to quality and innovation in the heart of China’s SiC industry.

Frequently Asked Questions (FAQ) about Nano Silicon Carbide

Navigating the world of advanced materials like nano silicon carbide can bring up many questions for engineers, procurement managers, and technical buyers. Here are some common queries with concise, practical answers to help you better understand this remarkable material and its applications.

- What are the primary differences in properties between nano silicon carbide and traditional micron-sized silicon carbide? Nano silicon carbide generally exhibits enhanced properties compared to its micron-sized counterparts due to its significantly smaller particle/grain size. These improvements often include:

- Higher Hardness and Strength: Due to the Hall-Petch effect (grain boundary strengthening).

- Improved Sinterability: Nano powders can often be sintered to higher densities at lower temperatures or shorter times.

- Enhanced Wear Resistance: Finer microstructures can lead to smoother surfaces and better resistance to abrasive wear.

- Greater Surface Area: Which can be beneficial for catalytic applications or for improving interfacial bonding in composites.

- Tailorable Optical and Electronic Properties: Quantum confinement effects can emerge in very small nanoparticles, altering these properties. However, challenges with nano powders include a higher tendency for agglomeration and potentially higher raw material costs. The specific property differences will also depend on the synthesis method, purity, and processing of both the nano and micron SiC.

- What are the main cost drivers for custom nano silicon carbide components? The cost of custom nano SiC components is influenced by several factors:

- Nano SiC Powder Cost: The synthesis route for high-quality, unagglomerated nano SiC powder is often more complex and expensive than for conventional SiC powders. Purity and specific particle characteristics also affect price.

- Component Complexity and Size: Intricate geometries, very large or very small parts, and features requiring specialized forming techniques (e.g., ceramic injection molding, additive manufacturing) will increase costs.

- Tolerances and Surface Finish: Tighter dimensional tolerances and ultra-smooth surface finish requirements necessitate more extensive and precise machining (diamond grinding, lapping, polishing), which is time-consuming and costly for hard ceramics like SiC.

- Sintering Process: Advanced sintering methods like Hot Isostatic Pressing (HIP) or Spark Plasma Sintering (SPS), often needed for optimal densification and microstructure control of nano SiC, are more expensive than conventional pressureless sintering.

- Order Volume (Quantity): As with most custom manufacturing, larger production volumes typically lead to lower unit costs due to economies of scale in setup, tooling, and processing. Small batches and prototypes will have higher per-unit costs.

- Quality Assurance and Testing: Extensive non-destructive testing (NDT) and characterization add to the cost but are crucial for high-performance applications. Sicarb Tech strives to provide cost-competitive customized silicon carbide components by leveraging its expertise, efficient processes, and the industrial advantages of the Weifang SiC hub.

- How does Sicarb Tech ensure the quality and reliability of its nano SiC products, especially given its location in China?Sicarb Tech ensures quality and reliability through a multi-faceted approach, leveraging its unique position and capabilities:

- Strong Technical Foundation: We are backed by the Chinese Academy of Sciences (Weifang) Innovation Park and the National Technology Transfer Center of the Chinese Academy of Sciences . This provides access to robust scientific and technological capabilities, advanced research, and a highly skilled talent pool.

- Expert Team: We possess a domestic top-tier professional team specializing in customized SiC production, with expertise spanning material science, process engineering, design, and advanced measurement & evaluation technologies.

- Integrated Process Control: We manage an integrated process from raw materials to finished products. This comprehensive oversight allows for stringent quality control at every stage – from powder selection and preparation to forming, sintering, machining, and final inspection.

- Advanced Technologies: We have supported over 10 local enterprises with our technologies, indicating a deep understanding and implementation of advanced SiC production techniques, crucial for nano SiC.

- Weifang SiC Hub Advantage: Being located in Weifang City, the hub of China’s SiC customizable parts manufacturing (over 80% of national output), gives us access to a mature supply chain, specialized ancillary services, and a skilled labor force. We have been instrumental in the technological advancement of this cluster since 2015.

- Commitment to Quality Assurance: Our processes include rigorous measurement and evaluation to ensure that all custom nano SiC components meet the specified quality and performance standards, providing more reliable quality and supply assurance within China. By combining the scientific backing of Chinese Academy of Sciences, our in-house expertise, strategic location, and commitment to technological excellence, Sicarb Tech delivers high-quality, reliable nano SiC products to both domestic and international clients.

Conclusion: Embracing the Nanoscale Advantage with Custom Silicon Carbide

The journey into the realm of nano silicon carbide reveals a material poised to redefine the limits of performance in countless industrial applications. Its exceptional hardness, superior thermal properties, remarkable wear resistance, and chemical inertness, all amplified at the nanoscale, offer solutions to challenges that conventional materials simply cannot meet. From the intricate demands of semiconductor manufacturing to the extreme environments of aerospace and high-temperature furnaces, custom nano SiC components are not just an upgrade but a fundamental enabler of innovation and efficiency.

The decision to incorporate custom nano SiC parts into your designs is an investment in unparalleled durability, precision, and operational excellence. While the path involves careful consideration of design intricacies, advanced manufacturing processes, and potential challenges, the rewards—extended product lifecycles, enhanced system performance, and the ability to operate in previously untenable conditions—are substantial.

Choosing the right partner is paramount in harnessing the full potential of this advanced ceramic. Sicarb Tech, strategically located in Weifang, the epicenter of China’s silicon carbide industry, stands as a testament to technological leadership and reliable supply. Our deep roots in the Chinese Academy of Sciences ecosystem, coupled with our hands-on experience in advancing SiC production technologies for numerous enterprises, provide us with a unique blend of scientific rigor and practical manufacturing prowess. We offer not only higher-quality, cost-competitive customized silicon carbide components but also the expertise to guide you from concept to a finished product that precisely meets your demanding specifications. For those looking to establish their own production capabilities, our technology transfer and turnkey project services offer a comprehensive solution.

As industries continue to push for smaller, faster, and more resilient technologies, the role of advanced materials like nano silicon carbide will only grow. We invite engineers, procurement managers, and technical buyers to explore the transformative possibilities with SicSino, your trusted partner for cutting-edge industrial SiC solutions.

About the Author: Sicarb Tech

We provide clear and reliable insights into silicon carbide materials, component manufacturing, application technologies, and global market trends. Our content reflects industry expertise, practical experience, and a commitment to helping readers understand the evolving SiC landscape.